A catalyst for dehydrogenating low-carbon alkanes to olefins and its preparation method and application

A low-carbon alkane and catalyst technology, which is applied in the field of low-carbon alkane dehydrogenation to olefin catalyst and its preparation field, can solve problems such as rapid coking, and achieve the effects of improving dispersity, high dehydrogenation activity, and high olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

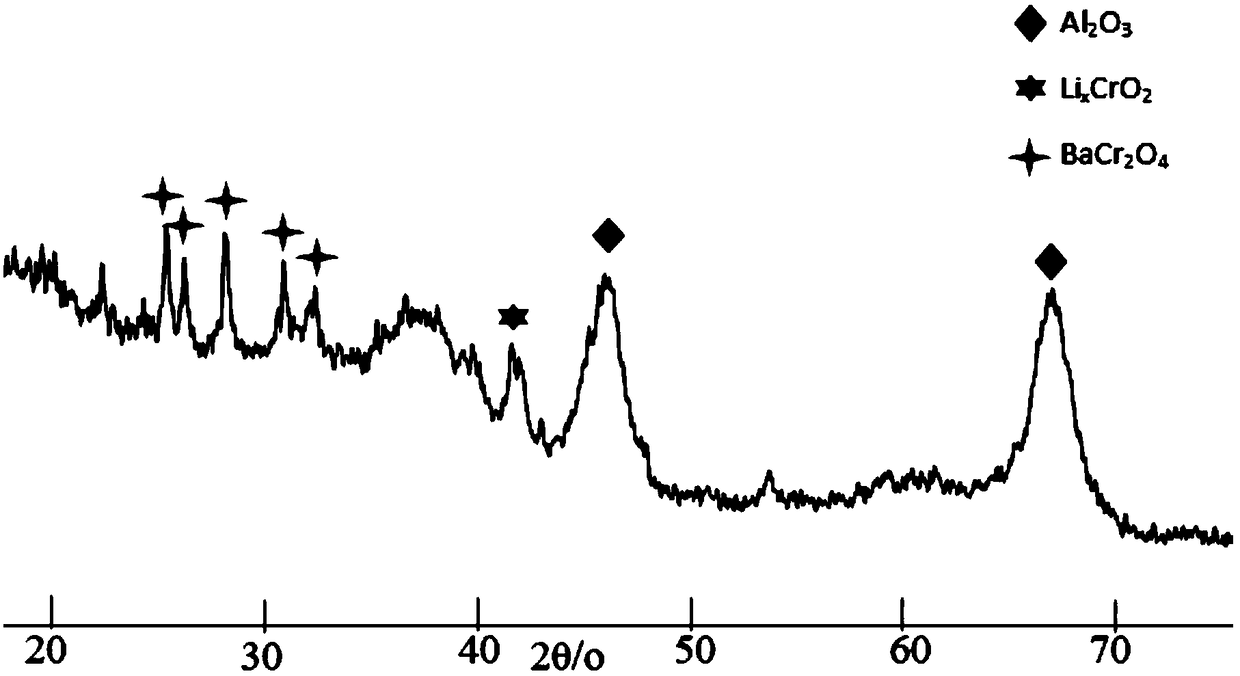

Image

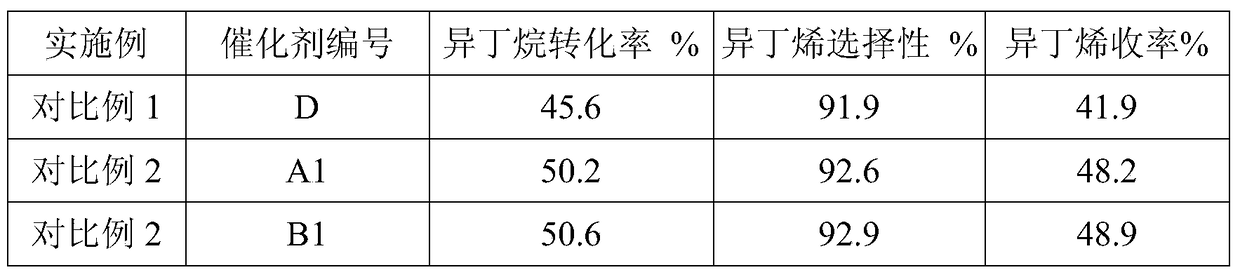

Examples

Embodiment 1

[0056] This embodiment provides a method for preparing a catalyst for dehydrogenating low-carbon alkanes to olefins, wherein the method includes the following steps:

[0057] 1. Preparation of alumina carrier:

[0058] Weigh 100g of macroporous pseudoboehmite powder produced by Shandong Aluminum Co., Ltd., add 2g of safflower powder, mix evenly, add dropwise 70mL of 1.5% nitric acid aqueous solution, fully knead, and extrude into a 1.6mm cylinder on the extruder The strips were dried in an oven at 120°C for 24 hours, and then fired in a muffle furnace at 800°C for 5 hours to obtain an alumina carrier.

[0059] 2. Preparation of barium-containing alumina carrier:

[0060] Take 100 g of the prepared alumina carrier, immerse in 200 mL of barium nitrate (the mass is respectively 1.94 g, 3.96 g, 6.05 g) aqueous solution (containing barium respectively 1%, 3%, 5%), and immerse for 2 hours Finally, take out the carrier, drain the solution, dry it in an oven at 120°C for 4 hours, an...

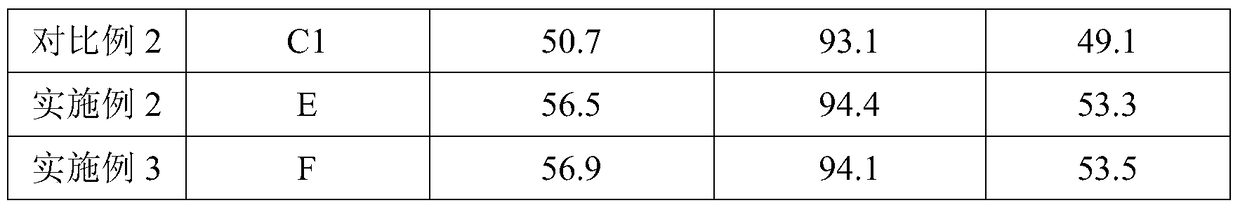

Embodiment 2

[0069] This embodiment provides a method for preparing a catalyst for dehydrogenating low-carbon alkanes to olefins, wherein the method includes the following steps:

[0070] Take 100 g of the barium-containing alumina carrier C prepared in step 2 of Example 1, impregnate it with 70 mL of chromic acid-sodium nitrate aqueous solution (with a Cr content of 12% and a Na content of 2%) with a pH value of 4, take it out after 2 hours, and let it dry in the air. After drying, it was dried in an oven at 120°C for 4 hours, and baked in a muffle furnace at 550°C for 4 hours to obtain a low-carbon alkane dehydrogenation olefins catalyst F (116.25g, in the shape of three lobes);

[0071] Based on the total weight of the low-carbon alkane dehydrogenation to olefins catalyst F as 100%, the low-carbon alkane dehydrogenation to olefins catalyst F prepared in Example 2 contains 4.8wt% barium oxide, 80.5wt% aluminum oxide, 13.2 wt% chromium oxide, 1.5wt% sodium oxide;

[0072] The low-carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com