Preparation method of efficient and visible-light catalytic function textile

A functional fabric and visible light technology, which is applied in the direction of plant fibers, animal fibers, textiles and papermaking, can solve the problems of wide band gap and fast electron-hole recombination, achieve high hydrophilicity, avoid the reduction of agglomeration efficiency, The effect of improving response efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

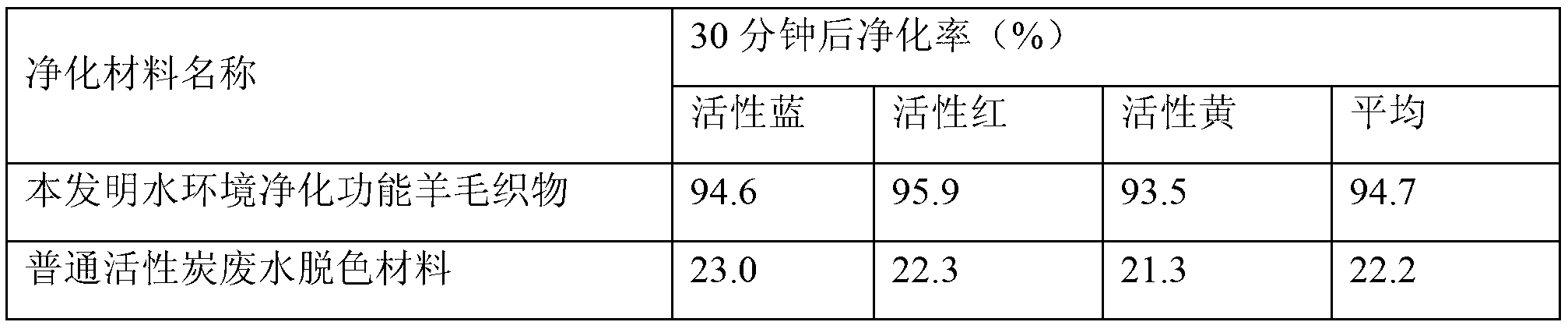

Embodiment 1

[0033] (1) Wool fabric surface pretreatment

[0034] Ultrasonic cleaning wool fabric (1g) with acetone for 30min, drying at 30°C for 3h, then treating it in high-efficiency detergent Kieralon OL (Basf) at 40°C for 25min, drying at 60°C for 10min, to obtain pretreated woolen fabric;

[0035] (2) Preparation of solution A

[0036] Add 5g of bismuth nitrate and 2.1g of citric acid into 100ml of nitric acid solution (2mol / L), stir until the solution is uniform and transparent, add dropwise a mixed solution of 1.2g of ammonium metavanadate and 1g of polyethylene glycol 2000 (PEG), and control The dropping rate was 3mL / min, and stirred at a speed of 300rpm for 2h to obtain solution A;

[0037] (3) Preparation of Suspension B

[0038] Adjust the pH of solution A to 8.5 with sodium hydroxide, raise the temperature to 90°C, and stir at a speed of 300rpm for 3h to obtain suspension B;

[0039] (4) Preparation of bismuth vanadate

[0040] Vacuum filter the suspension B, rinse the fil...

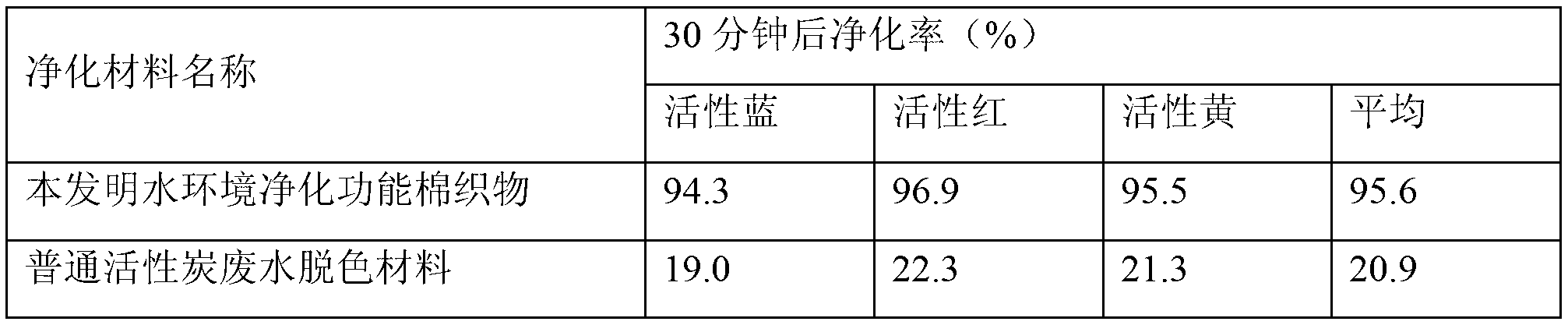

Embodiment 2

[0050](1) Cotton fabric surface pretreatment

[0051] Clean the cotton fabric (1g) ultrasonically with ethanol for 40min, dry at 30°C for 3h, then treat it in the high-efficiency cleaning agent Span-one (Desang Chemical) solution at 45°C for 25min, and dry at 65°C for 5min to obtain pretreated cotton fabric;

[0052] (2) Preparation of Solution A

[0053] Add 7.5g of bismuth nitrate and 3g of citric acid into 100ml of nitric acid solution (4mol / L), stir until the solution is uniform and transparent, add dropwise a mixed solution of 1.8g of ammonium metavanadate and 1g of polyethylene glycol 2000 (PEG), and control The dropping rate was 3mL / min, and stirred at a speed of 300rpm for 2h to obtain solution A;

[0054] (3) Preparation of Suspension B

[0055] Adjust the pH of solution A to 8 with sodium hydroxide, raise the temperature to 80°C, and stir at 300rpm for 3h to obtain suspension B;

[0056] (4) Preparation of bismuth vanadate

[0057] Vacuum filter the suspension B,...

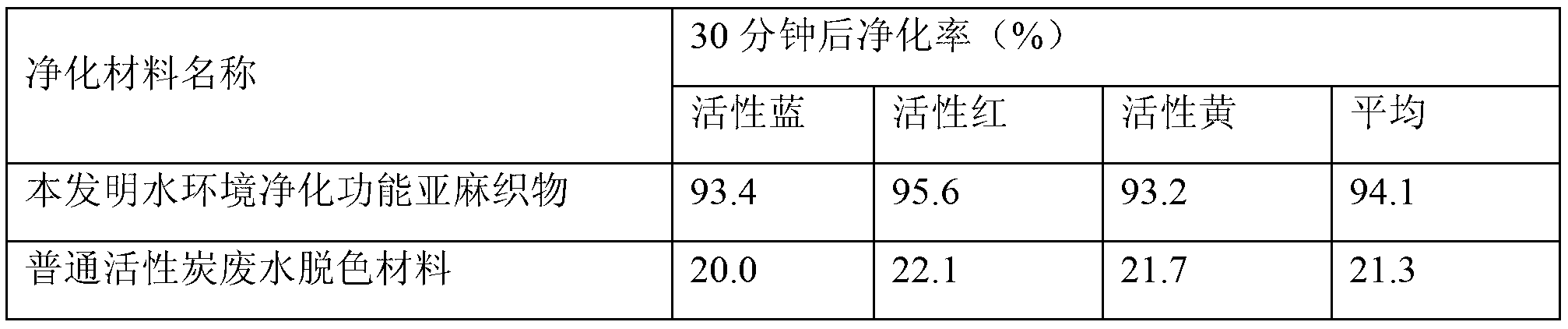

Embodiment 3

[0067] (1) Surface pretreatment of linen fabric

[0068] Ultrasonic cleaning of linen fabric (1g) with acetone for 60min, drying at 30°C for 3h, then treating in high-efficiency detergent LS (Demei Chemical) solution at 40°C for 25min, drying at 60°C for 10min, to obtain pretreated linen fabric;

[0069] (2) Preparation of Solution A

[0070] Add 5g of bismuth nitrate and 2.1g of citric acid into 80ml of nitric acid solution (3mol / L), stir until the solution is uniform and transparent, add dropwise a mixed solution of 1.2g of ammonium metavanadate and 0.5g of polyethylene glycol 2000 (PEG), Control the dropping rate to 2mL / min, stir at a speed of 300rpm for 2h to obtain solution A;

[0071] (3) Preparation of Suspension B

[0072] Adjust the pH of solution A to 8 with sodium hydroxide, raise the temperature to 90°C, and stir at a speed of 300rpm for 2h to obtain suspension B;

[0073] (4) Preparation of bismuth vanadate

[0074] Vacuum filter the suspension B, rinse the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com