Method for preparing upholstery multifunctional air purification function fabric for public transport means

A technology for public transportation and air purification, which is applied in plant fibers, textiles, papermaking, fiber treatment, etc. It can solve the problems of easy poisoning and failure of catalysts, inconvenient use, and affecting performance, so as to achieve no secondary pollution and low cost , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

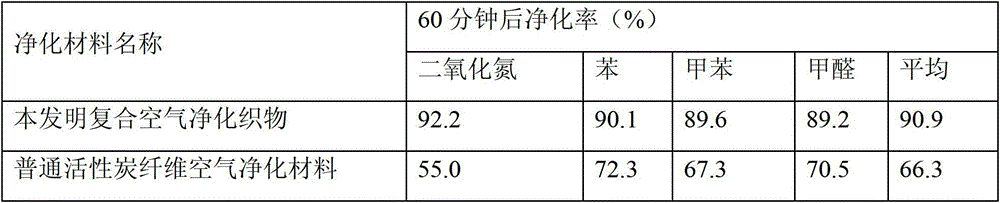

Embodiment 1

[0029] (1) The nano Fe 3 O 4 4g of granules, 1g of sodium dodecylbenzene sulfonate, 4g of methyltrimethoxysilane and 2g of ammonium polyphosphate were mixed, dispersed by ultrasonic for 30 minutes, stirred at 200r / min for 1 hour, and the reaction temperature was controlled at 30℃, 100r / Min stirring, using acetic acid as a catalyst, adding 5ml of acetic acid to the system in batches, adding it within 2 hours, and then continuing to stir for 1 hour, then immerse the fabric in it, process it in a normal pressure shaking dyeing machine, and take it out naturally Air-dry, the dried polyester-cotton fabric is baked at 120°C for 1 hour.

[0030] (2) Add 0.05mol bismuth nitrate, 0.005mol ethylenediaminetetraacetic acid disodium and 0.005mol cetyltrimethylammonium bromide to 200mL phosphate buffer under stirring at 500r / min, and then add step (1) Add 5g of the fabric treated in the medium, and then add 200mL of phosphate buffer containing 0.05mol ammonium metaaluminate dropwise, after th...

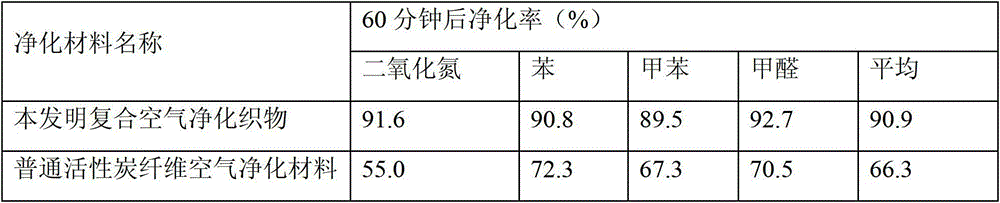

Embodiment 2

[0034] (1) The nano Fe 3 O 4 Granules 4g, sodium dodecylbenzene sulfonate 1g, methyltrimethoxysilane 4g, ammonium polyphosphate 2g,

[0035] Mix, use ultrasonic dispersion for 30 minutes, stir at 400r / min for 1 hour, control the reaction temperature at 55°C, stir at 150r / min, use acetic acid as a catalyst, add 5ml of acetic acid to the system in batches, add it within 2 hours, and then Continue to stir for 1 hour, then immerse the fabric in it, process it in a normal pressure oscillating dyeing machine, and then take it out to air dry. The dried polyester-cotton fabric is baked at 140°C for 1 hour.

[0036] (2) 0.1mol bismuth chloride, 0.025mol tetrasodium edetate and 0.075mol cetyltrimethylammonium bromide were gradually added to 200mL phosphate buffer under stirring at 1000r / min, and then added For 10g of the fabric treated in step (1), add 200mL of phosphate buffer containing 0.01mol potassium metavanadate dropwise, after the dropwise addition, adjust the pH of the reaction syst...

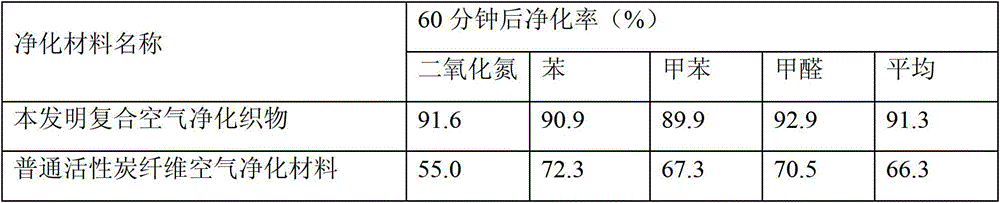

Embodiment 3

[0041] (1) The nano Fe 3 O 4 Granules 4g, sodium dodecylbenzene sulfonate 1g, methyltrimethoxysilane 4g, ammonium polyphosphate 2g,

[0042] Mix, use ultrasonic dispersion for 30 minutes, stir at 400r / min for 1 hour, control the reaction temperature at 80°C, stir at 200r / min, use acetic acid as a catalyst, add 5ml of acetic acid to the system in batches, add it within 2 hours, and then Continue to stir for 1 hour, then immerse the fabric in it, process it in a normal pressure shaking dyeing machine, and then take it out to air dry. The dried polyester-cotton fabric is baked at 160°C for 1 hour.

[0043] (2) Gradually add 0.15mol bismuth acetate, 0.05mol sodium gluconate and 0.01mol cetyltrimethylammonium bromide to 200mL phosphate buffer under stirring at 1500r / min, and then add to step (1) 15g of treated fabric,

[0044] Then add dropwise 200 mL of phosphate buffer containing 0.15 mol metaaluminate, after the addition, adjust the pH of the reaction system to 9 with 1 mol / L sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com