Method for in situ preparing Au modified and TiO2 compound air purified functional textile at low temperature

An air purification, low-temperature in-situ technology, applied in plant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of easy photo-oxidative degradation of flexible substrates, low temperature resistance of flexible substrates, and low catalytic efficiency. The effect of reduced agglomeration efficiency, no secondary pollution, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

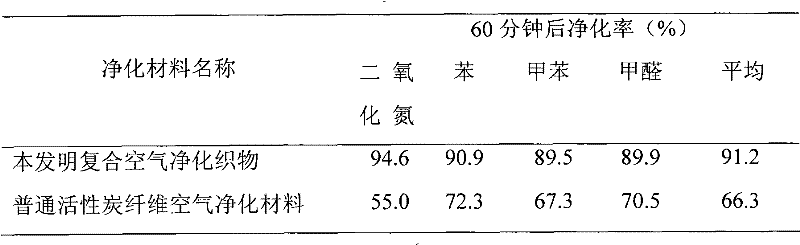

Embodiment 1

[0031] (1) Wool fabric surface pretreatment

[0032] Ultrasonic cleaning of wool fabric with acetone solution for 30 minutes, drying at room temperature 20°C for 12 hours, then treating in BASF's high-efficiency cleaning agent Kieralon OL solution at 40°C for 20 minutes, and drying at 80°C for 30 minutes;

[0033] (2) Protective finishing of wool fabric against photooxidation

[0034] Take out the wool fabric padding fiber anti-oxidation finishing solution LZQ for 30 minutes, pre-bake at 70°C, and then heat up to 130°C for 2 minutes; the LZQ finishing solution is composed of 1-3% Tween 80, 4-10% nano-hydroxy Apatite HAP40, 3-8% tetraerythritol ester, 6-10% octyltrimethoxysilane and 69-86% water;

[0035] (3) Preparation of low temperature precursor

[0036] Under an inert environment, slowly add 0.02mol titanium tetraisopropoxide to 30mL isopropanol under stirring, add 0.01mol triethylamine as a stabilizer to the mixture, stir at 200rpm for 1min, and then continue to add 20m...

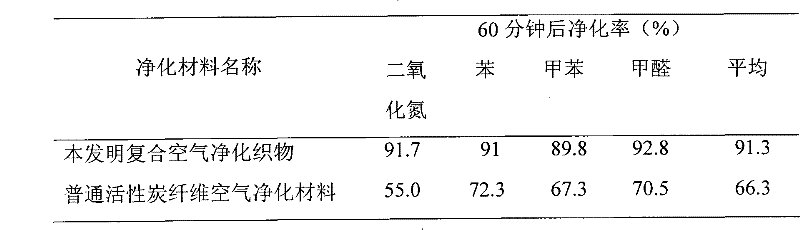

Embodiment 2

[0044] (1) Cotton fabric surface pretreatment

[0045] Ultrasonic cleaning of cotton fabrics with acetone solution for 40 minutes, drying at room temperature 25 ° C for 14 hours, and then in BASF’s high-efficiency cleaning agent Kieralon OL solution for 25 minutes at 43 ° C, and drying at 83 ° C for 37 min;

[0046] (2) Protective finishing of cotton fabric against photooxidation

[0047] Take out the cotton fabric padding fiber anti-oxidation finishing solution LZQ for 40 minutes, pre-dry at 75°C, and then heat up to 140°C for 3 minutes; the LZQ finishing solution is composed of 1-3% Tween 80, 4-10% nano-hydroxy Apatite HAP40, 3-8% tetraerythritol ester, 6-10% octyltrimethoxysilane and 69-86% water.

[0048] (3) Preparation of low temperature precursor

[0049] Under an inert environment, slowly add 0.08mol titanium tetraisopropoxide to 40mL isobutanol under stirring, add 0.02mol triethylamine as a stabilizer to the mixture, stir at 250rpm for 2min, and then continue to add...

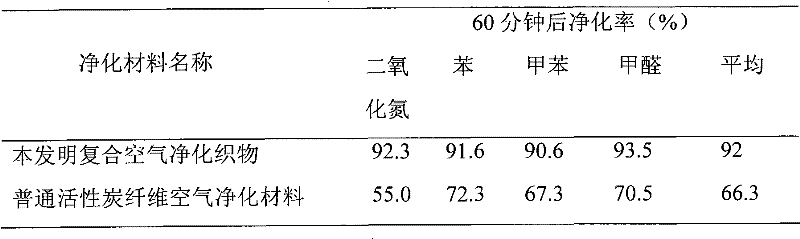

Embodiment 3

[0057] (1) Surface pretreatment of linen fabric

[0058] Ultrasonic cleaning of cotton fabrics with acetone solution for 50 minutes, drying at room temperature at 30°C for 16 hours, then treating in BASF’s high-efficiency cleaning agent Kieralon OL solution at 45°C for 30 minutes, and drying at 85°C for 45 minutes;

[0059] (2) Protective finishing of linen fabric against photooxidation

[0060] Take out the linen fabric padding fiber anti-oxidation finishing solution LZQ for 50 minutes, pre-bake at 80°C, and then heat up to 150°C for 4 minutes; the LZQ finishing solution is composed of 1-3% Tween 80, 4-10% nano-hydroxy Apatite HAP40, 3-8% tetraerythritol ester, 6-10% octyltrimethoxysilane and 69-86% water.

[0061] (3) Preparation of low temperature precursor

[0062] Under an inert environment, slowly add 0.15 mol of titanium tetraisopropoxide to 50 mL of isobutanol under stirring, add 0.03 mol of triethylamine as a stabilizer to the mixture, stir at 300 rpm for 4 min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com