Preparation method of interface plasma modified and amphiphilic fiber-based purifying material

A technology of plasma and purification materials, which is applied in the field of preparation of ion-modified amphiphilic fiber-based purification materials, can solve the problems of reduced specific surface area, catalyst adsorption and light absorption efficiency, and achieve low cost and avoid agglomeration efficiency decline , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Surface pretreatment of polyester fabric

[0030] Ultrasonic cleaning of polyester fabric (1g) with acetone solution for 30min, drying at 40°C for 1h, then treating in Kieralon OL (Basf) solution for 15min at 50°C, drying at 50°C for 30min;

[0031] (2) Treat the treated polyester fabric with atmospheric pressure glow discharge for 60s in an air environment;

[0032] (3) Take 0.005mol of bismuth nitrate and add it to 50ml of nitric acid solution (2mol / L), and dropwise add Tween 80, a wetting agent 2% relative to the weight of the fabric, stir at 200rpm for 30min, and add 4g of NaHCO 3 ; Add 0.005mol of ammonium metavanadate to 50ml of deionized water, stir at 200rpm for 5min, and add 10ml of sodium hydroxide solution (2.5mol / L) dropwise during stirring to obtain a clear solution;

[0033] (4) Preparation of unactivated photocatalyst

[0034] Add the above solution B to the above solution A dropwise, control the transfer rate to 1.5ml / min, mix uniformly to form a fin...

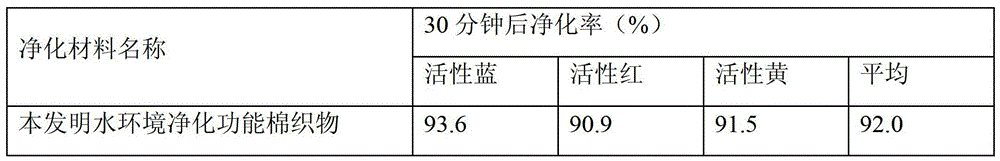

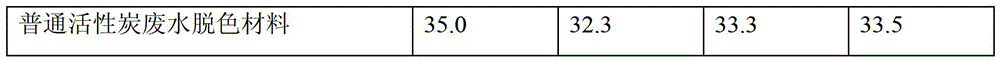

Embodiment 2

[0042] (1) Cotton fabric surface pretreatment

[0043] Clean the cotton fabric (1g) ultrasonically with acetone solution for 60min, dry at 50°C for 2h, then treat it in the detergent Kieralon OL (Basf) solution at 55°C for 20min, and dry at 50°C for 30min;

[0044] (2) Treat the treated cotton fabric with atmospheric pressure glow discharge for 70s in an air environment;

[0045] (3) Take 0.005mol of bismuth nitrate and add it to 50ml of nitric acid solution (2mol / L), and dropwise add a wetting agent JFC 2% relative to the weight of the fabric, stir at 200rpm for 30min, add 4g of Na 2 CO 3 ; Add 0.005mol ammonium metavanadate to 50ml deionized water, stir at 200rpm for 5min, and add 10ml sodium hydroxide solution (3mol / L) dropwise during the stirring process,

[0046] A clear solution is obtained;

[0047] (4) Preparation of unactivated photocatalyst

[0048] Add the above solution B to the above solution A dropwise, control the transfer rate to 1.5ml / min, mix uniformly to...

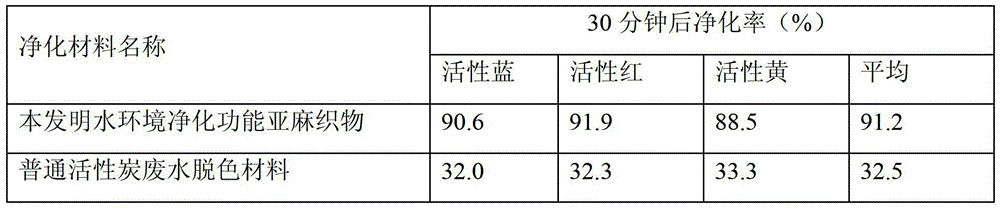

Embodiment 3

[0057] (1) Surface pretreatment of linen fabric

[0058] Clean the linen fabric (1g) ultrasonically with acetone solution for 40min, dry at 40°C for 1h, then treat it in the detergent Kieralon OL (Basf) solution at 50°C for 15min, and dry at 40°C for 20min;

[0059] (2) The treated linen fabric was treated with atmospheric pressure glow discharge for 50s in an air environment with a plasma instrument;

[0060] (3) Take 0.005mol of bismuth nitrate and add it to 50ml of nitric acid solution (2mol / L), and dropwise add Tween 80, a wetting agent 2% relative to the weight of the fabric, stir at 200rpm for 30min, and add 4g of NaHCO 3 ; Add 0.005mol of ammonium metavanadate to 50ml of deionized water, stir at 200rpm for 5min, and add 10ml of sodium hydroxide solution (2.5mol / L) dropwise during stirring to obtain a clear solution;

[0061] (4) Preparation of unactivated photocatalyst

[0062] Add the above solution B to the above solution A dropwise, control the transfer rate to 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com