Preparation method for corrosion-resistant and super-hydrophobic aluminum oxide membrane for zinc layer

An alumina and corrosion-resistant technology, which is used in the preparation of corrosion-resistant super-hydrophobic materials, can solve the problems of poor controllability of the size and shape of the micro-rough structure on the super-hydrophobic surface, and achieves improved corrosion resistance, improved corrosion resistance, and improved surface uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The molar ratio of aluminum isopropoxide: water: ethyl acetoacetate: nitric acid is 1:300:1:0.5, take aluminum isopropoxide 11.35 g, water 300 g, ethyl acetoacetate 7.17 g, nitric acid (H + The molar ratio of water to water is 0.00167) 1.75 g, which are added to the three-necked flask in turn, and stirred at 85 °C for 1 h to obtain an alumina sol with uniform particle size and good dispersibility.

[0033] The zinc plate was immersed in the prepared alumina sol and etched for 2 h.

[0034] The etched zinc plate was modified by immersing in 167 mL / L hexamethyldisilazane solution for 2 h to obtain a superhydrophobic coating with a thickness of about 1 μm. The hydrophobic angle of the film is 153°, the sliding angle is less than 10°, and through the salt spray test, the time for 5% of the white rust area to appear is 99h, indicating that its corrosion resistance is good.

Embodiment 2

[0036] The molar ratio of aluminum isopropoxide: water: ethyl acetoacetate: nitric acid is 1:250:1:0.5, take aluminum isopropoxide 11.35 g, water 250 g, ethyl acetoacetate 7.17 g, nitric acid (H + Molar ratio of 0.002) to water, 1.75 g, was added to the three-necked flask in turn, and stirred at 80 °C for 2 h to obtain an alumina sol with uniform particle size and good dispersion.

[0037] The hot-dip galvanized sample was immersed in the prepared alumina sol and etched for 2 h.

[0038] The etched hot-dip galvanized sample was modified by immersing in 125mL / L hexamethyldisilazane solution for 2 h to obtain a superhydrophobic coating with a thickness of about 3um. The hydrophobic angle of the film is 157°, the sliding angle is less than 10°, and through the salt spray test, the time for 5% of the white rust area to appear is 106h, indicating that its corrosion resistance is good.

Embodiment 3

[0040] With the molar ratio of aluminum isopropoxide: water as 1:100, take 11.35 g of aluminum isopropoxide and 100 g of water into a three-necked flask in turn, and stir at 85°C for 24 hours to obtain an alumina sol with uniform particle size and good dispersibility.

[0041] The zinc plate was immersed in the prepared alumina sol and etched for 2 h.

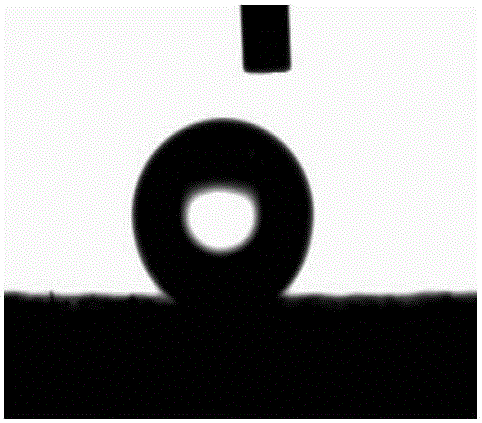

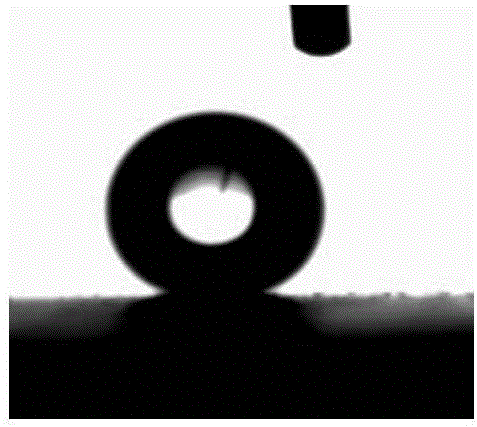

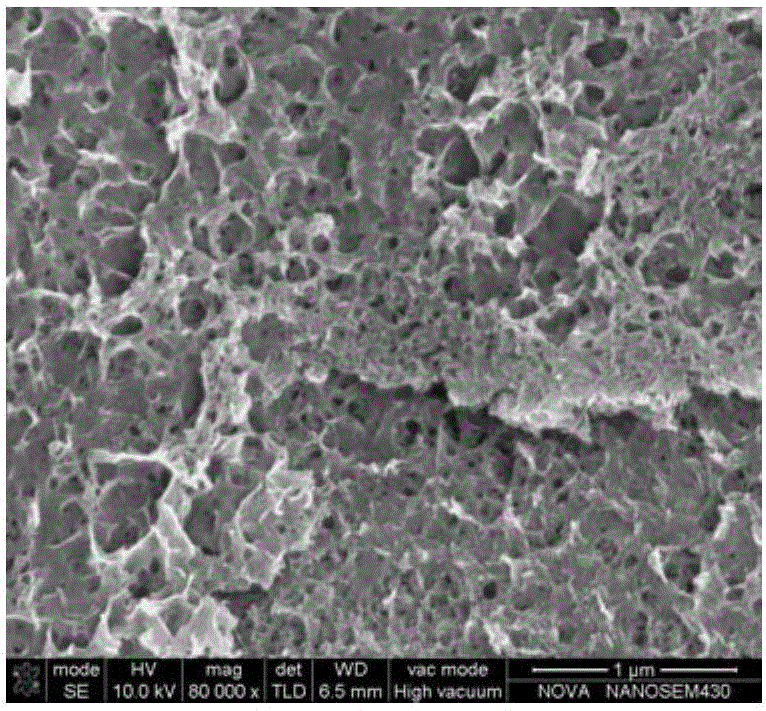

[0042] The etched zinc plate was modified by immersing it in 100 mL / L hexamethyldisilazane solution for 2 h to obtain a superhydrophobic film with a thickness of about 3 μm. The hydrophobic angle of the film is 152°, the sliding angle is less than 10°, and through the salt spray test, the time for 5% of the white rust area to appear is 98h, indicating that its corrosion resistance is good. The contact angle photos and SEM photos of the superhydrophobic film layer prepared in this embodiment are respectively as follows figure 1 , image 3 shown. From image 3 It can be seen that a micro-nano-scale honeycomb structure with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

| Sliding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com