Ternary cross-linked hydrogel electrolyte, preparation method and applications thereof

A technology for cross-linking hydrogels and electrolytes, applied in the field of functional polymers, can solve the problems of poor self-healing performance and inconvenient preparation methods, and achieve the effects of easy operation, good biocompatibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

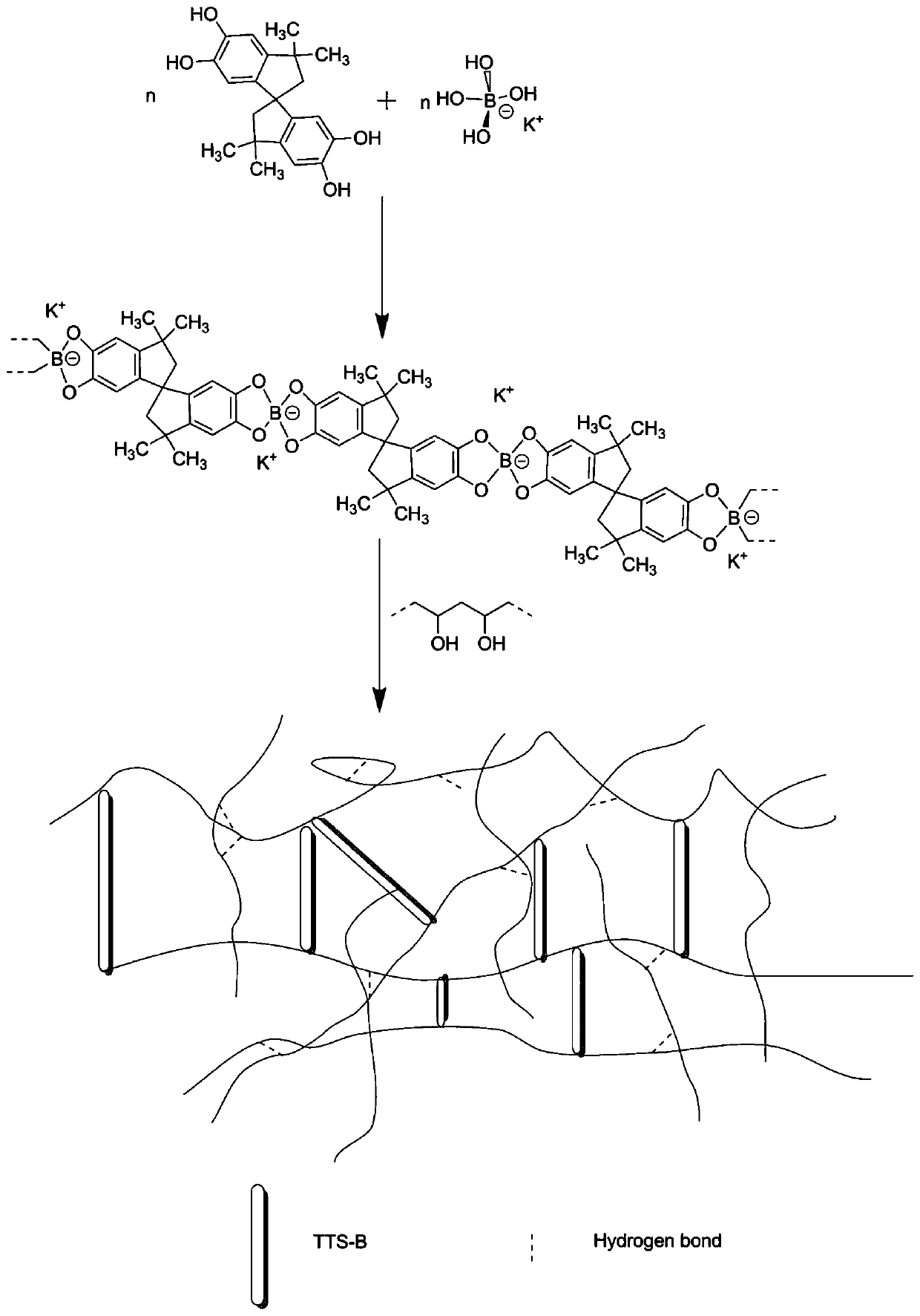

Method used

Image

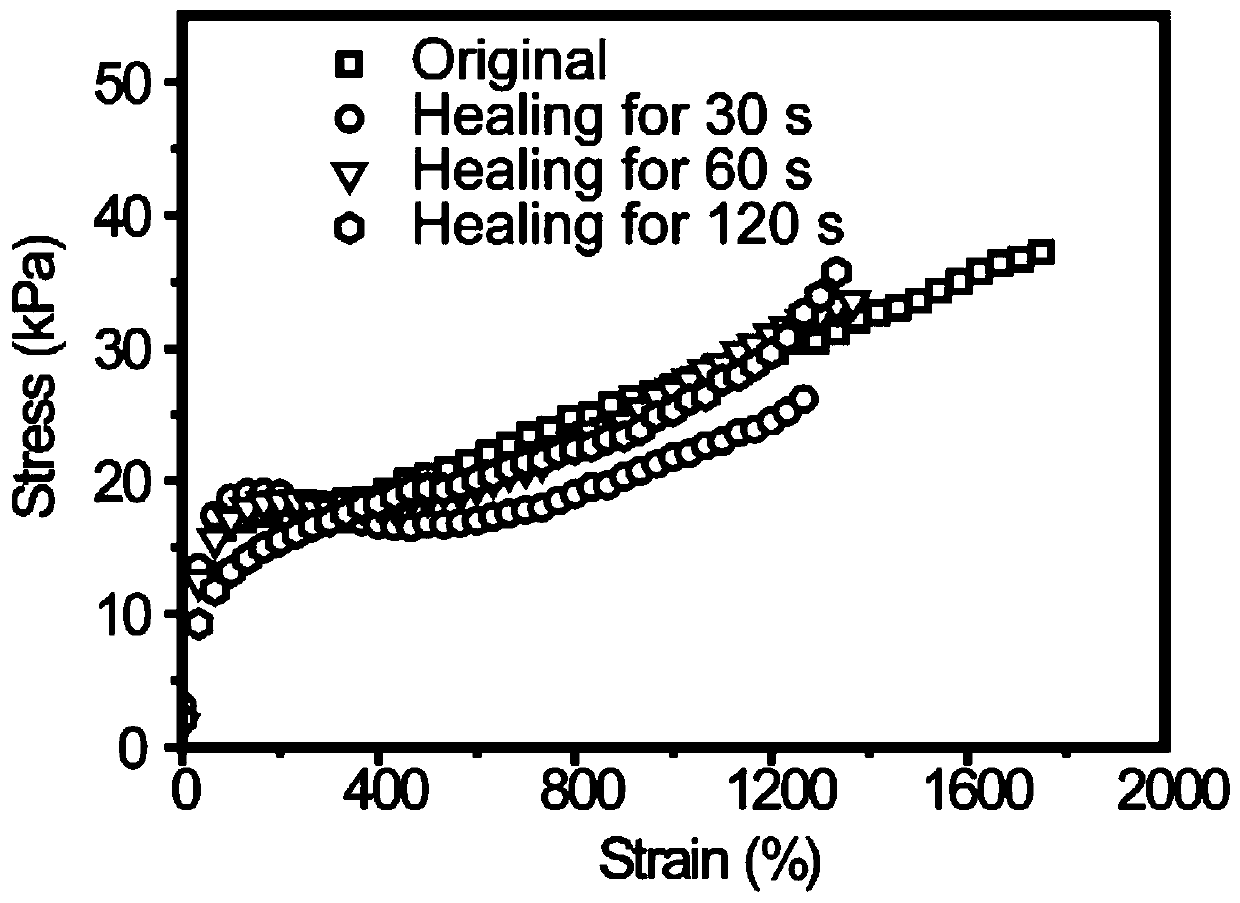

Examples

Embodiment 1

[0026] (1) Add 1g 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-helical bisindane (TTS), 1g boric acid, 1g hydrogen Potassium oxide was dissolved in 25 g of distilled water and ultrasonically dispersed for 30 minutes.

[0027] (2) The above solution was heated and reacted at 90° C. for 2 h to obtain a pink dispersion.

[0028] (3) Dissolve 10 g of PVA in 63 g of water in an oil bath at 98°C.

[0029] (4) At 90°C, slowly add the above-mentioned dispersion liquid into the polyvinyl alcohol aqueous solution.

[0030] (5) Stir the reaction in an oil bath at a temperature of 90° C. for 1 hour. The sample was cooled to obtain a light brown hydrogel.

Embodiment 2

[0032] (1) Add 3g of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-helical bisindane (TTS), 1g of boric acid, 1g of hydrogen Potassium oxide was dissolved in 25 g of distilled water and ultrasonically dispersed for 30 minutes.

[0033] (2) The above solution was heated and reacted at 90° C. for 2 h to obtain a pink dispersion.

[0034] (3) Dissolve 10 g of PVA in 60 g of water in an oil bath at 98°C.

[0035] (4) At 90°C, slowly add the above-mentioned dispersion liquid into the polyvinyl alcohol aqueous solution.

[0036] (5) Stir the reaction in an oil bath at a temperature of 90° C. for 1 hour. The sample was cooled to obtain a light brown hydrogel.

Embodiment 3

[0038] (1) Add 4g of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-helical bisindane (TTS), 1g of boric acid, 1g of hydrogen Potassium oxide was dissolved in 25 g of distilled water and ultrasonically dispersed for 30 minutes.

[0039] (2) The above solution was heated and reacted at 90° C. for 2 h to obtain a pink dispersion.

[0040] (3) Dissolve 10 g of PVA in 59 g of water in an oil bath at 98°C.

[0041] (4) At 90°C, slowly add the above-mentioned dispersion liquid into the polyvinyl alcohol aqueous solution.

[0042] (5) Stir the reaction in an oil bath at a temperature of 90° C. for 1 hour. The sample was cooled to obtain a light brown hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com