Polymer sulfur coated controlled release fertilizer and preparing method thereof

A technology for slow-release fertilizers and manufacturing methods, applied in the direction of layered/coated fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of high coating rate, complex production process, and high equipment requirements, and achieve improved impact resistance and performance Abrasion resistance, increased nutrient content, and the effect of less membrane material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

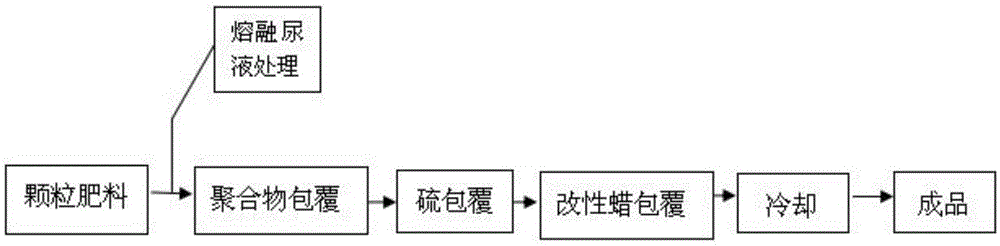

Method used

Image

Examples

specific Embodiment

[0024] 1. Urea granules (the weight accounts for 92% of the total weight of the granular fertilizer, wherein the weight percentage of nitrogen is 42% (42N), first preheats, sprays urea melt, accounts for 0.2% of the total weight of the granular fertilizer, and adds 0.3 % alginic acid. Secondly, polymer coating (reaction by vegetable oil-based isocyanate and vegetable oil polyol), spraying thickness is based on 2% of the total weight of the granular fertilizer, and again is a modified sulfur coating, accounting for 5.5% of the total weight of the granular fertilizer, Finally, the natural modified polymer wax is coated, accounting for 0.3% of the total weight of the granular fertilizer. The finished product (42-0-0-0.2U-2P-5.5S-0.3W) is measured and packaged, and the dissolution rate in 24 hours is 3.2%.

[0025] 2. Urea granules (the weight accounts for 94% of the total weight of the granular fertilizer, wherein the weight percentage of nitrogen is 43% (43N)), first preheating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com