Ultra thin laminate with particulates in dense packages

a technology of ultra-thin laminates and dense packages, applied in the field of thin, laminated materials, can solve the problems of reducing the structural integrity of the core structure, exacerbated, and affecting and achieve the effect of promoting the uniformity of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Material Example 1

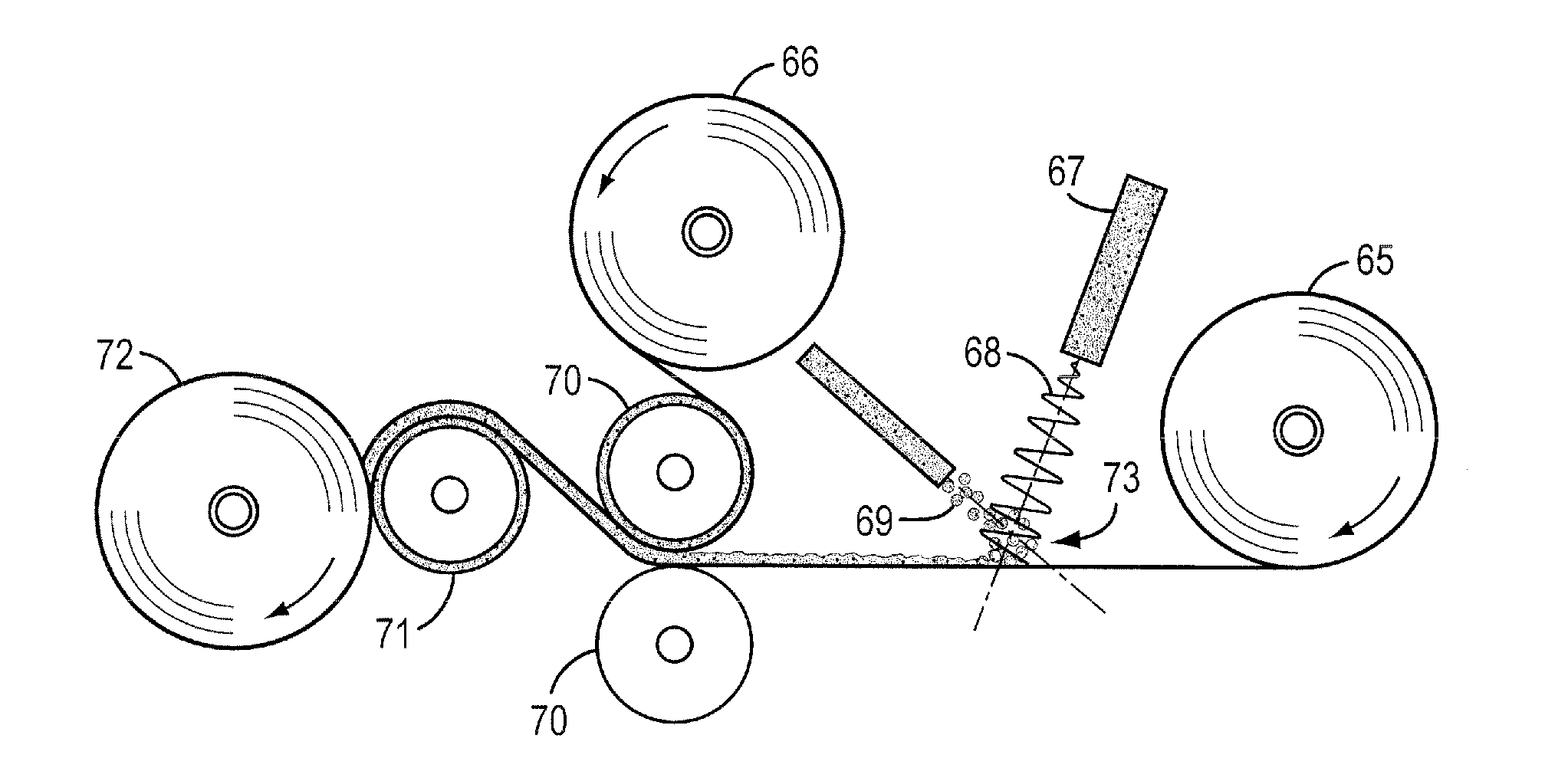

[0112]A 17 gsm web of type 3207 Tissue from Cellu Tissue in East Hartford, Conn. was unwound from an undriven spindle at 85 m / min. It was run under a ITW Dynatec UFD hot melt glue head with Omega nozzles at a distance approximately 60 mm from the nozzle orifices. The adhesive flow was set to deliver approximately 6 gsm of NW1023 hot melt adhesive from HB Fuller in a pattern 200 mm wide at an applicator temperature of 350 F and an air pressure of 20 psi. A 200 mm wide stream of SA 70 Superabsorbent Polymer from Sumitomo Seika Ltd, Osaka, Japan was metered to flow down an inclined plate at a rate to deposit 80 gsm onto the moving web. The SAP stream axis was directed to intersect with the hot melt adhesive stream axis at a point approximately 1 cm above the surface of the moving tissue and the resulting mixture of SAP and adhesive fibers were immediately deposited onto the tissue. A second 17 gsm web of type 3207 tissue from Ceilu Tissue in East Hartford, Conn. was u...

example 2

Material Example 2

[0113]Similar to Material Example 1 except the SAP add-on was 20 gsm, the adhesive add-on was 3 gsm, and the web speed was 184 m / minute. The package pressure was adjusted to be sufficient to produce a roll density of approximately 0.40 g / cc.

MCBThicknessRewetFPTVDS(g)(mm)(g)(s)(N)Inventive771.90.31112Sample 1Inventive281.20.42314Sample 2

[0114]Applications of the absorbent article according to the present invention for sanitary and other health-care uses can be accomplished by any sanitary protection, incontinence, medical and absorbent methods and techniques as are presently or prospectively known to those skilled in the art. Thus, it is intended that the present application cover the modifications and variations of this invention provided that they come within the scope of the appended claims and their equivalents.

[0115]Presuming the applicant's theory about the surfaces nesting is correct, the following are some observations and projections that might be made to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com