Soft tissue paper containing fine particulate fillers

A particle filler, tissue paper technology, applied in the field of tissue paper products, can solve problems such as reducing softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

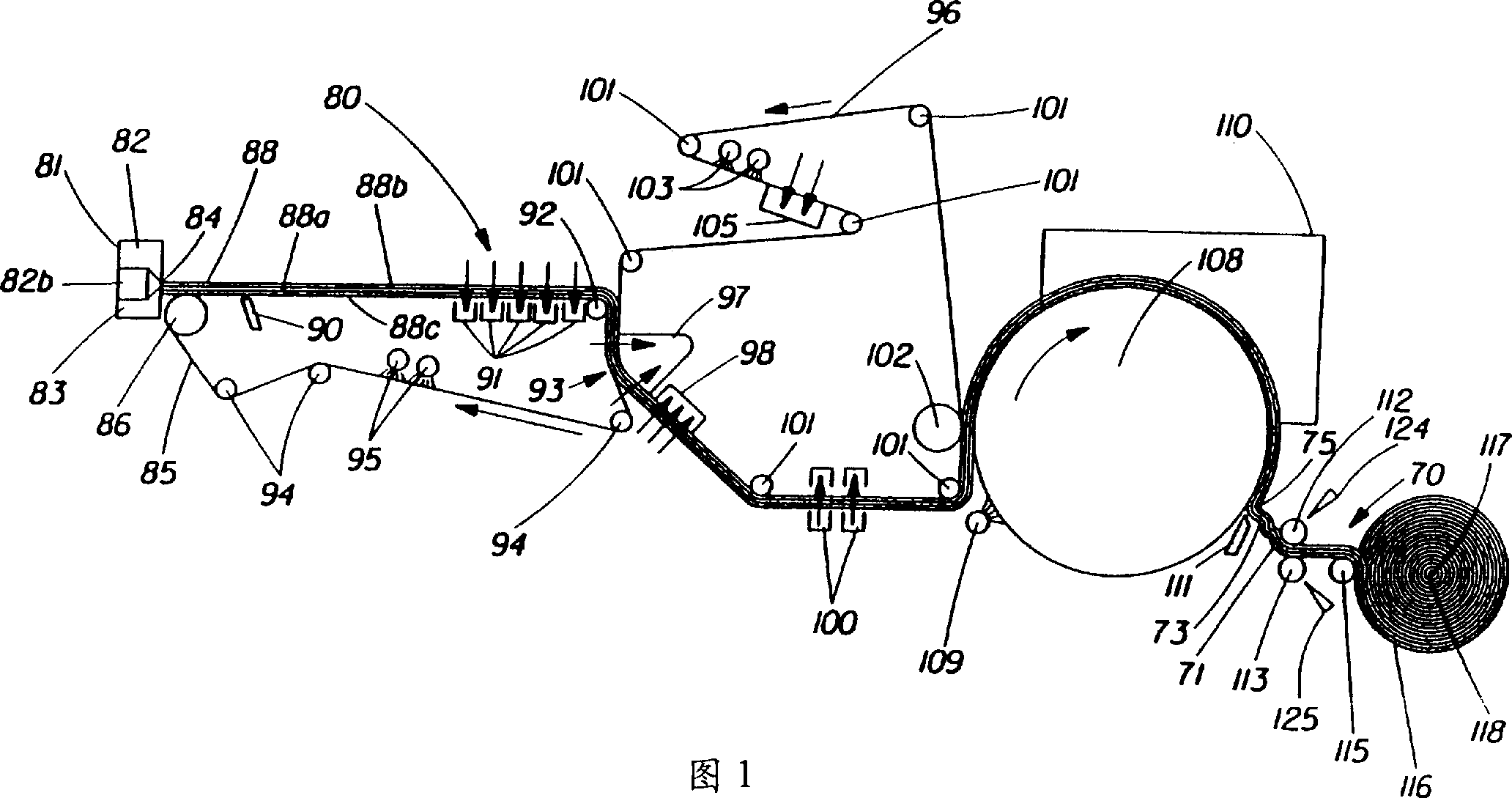

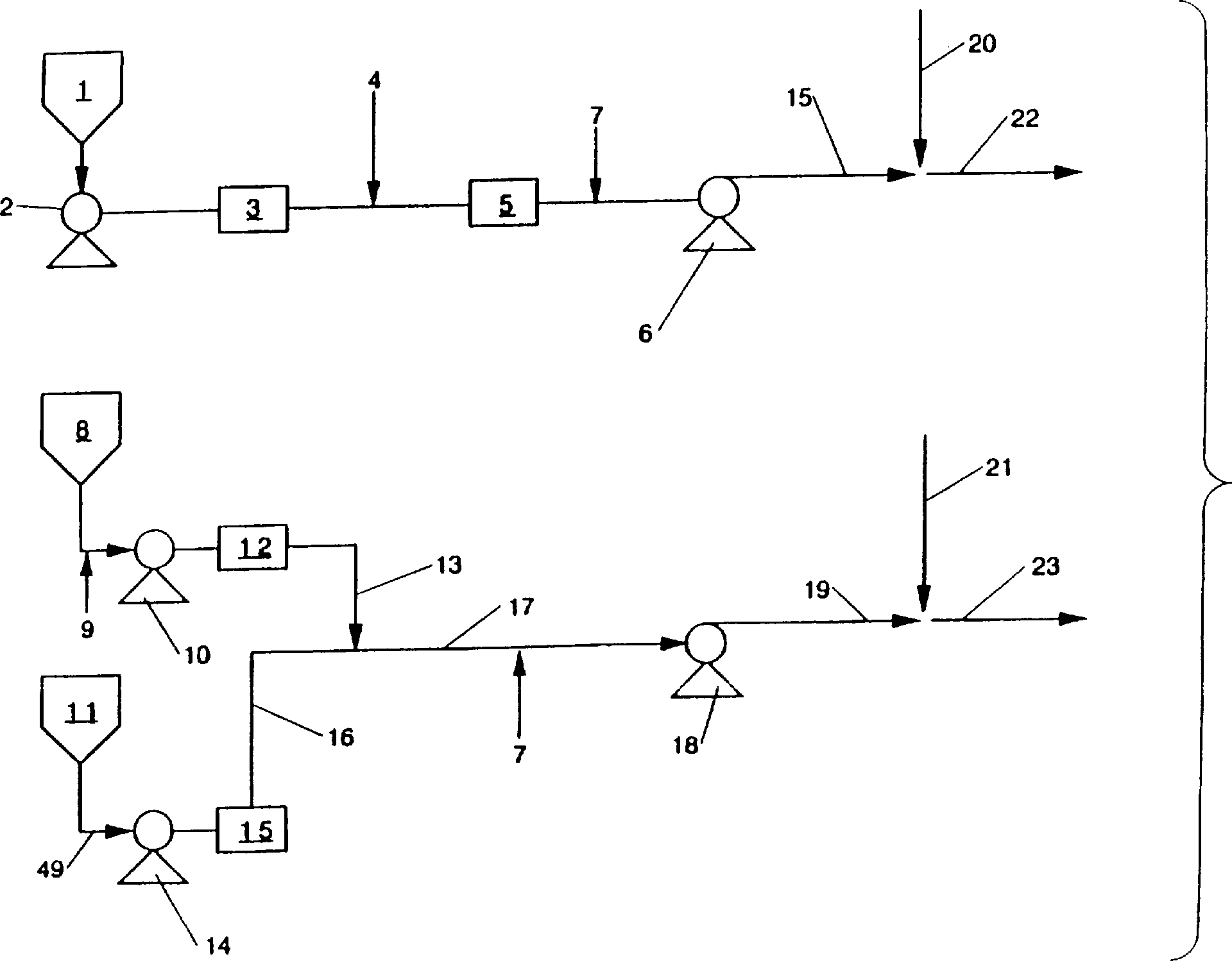

[0280] This comparative example is a comparative example illustrating a reference method that does not incorporate the features of the present invention. This method is illustrated in the following steps:

[0281] An aqueous slurry of about 3% by weight eucalyptus fibers was made using a customary pulper. Cypro 514 was added at a rate of 0.02% dry weight relative to the final dry weight of the creped tissue into the slurry. This treated slurry is then sent to the paper machine through the feed pipe.

[0282] The particulate filler was grade WWFil Slurry manufactured by Dry Branch Kaolin of Dry Branch, GA kaolin clay. It is delivered as a 70% solids slurry through the feed pipe with an anionic flocculant - Accurac 62 - delivered as a 0.3% aqueous dispersion mixed. Accurac 62 It is delivered at a rate corresponding to about 0.015% of the dry weight of the flocculant to the finished dry weight of the creped tissue paper produced. The flocculant adsorption capacity...

Embodiment 2

[0300] This example illustrates one embodiment of the invention for making filled tissue paper.

[0301] An aqueous slurry of about 3% by weight eucalyptus fibers was prepared using a conventional pulper. Add Cypro 514 at a dry weight ratio of 0.02% relative to the final dry weight of the creped tissue into the slurry. This treated slurry is then fed to the paper machine through the stock pipe.

[0302] The particulate filler was kaolin clay grade WWFil Slurry(R) manufactured by Dry Branch Kaolin of Dry Branch, GA. It is conveyed through the raw material pipe as a slurry with a solid content of 70%, and in the raw material pipe with an anionic flocculant—Accurac 62 conveyed as a 0.3% aqueous dispersion mixed. Accurac62 It is delivered at a rate corresponding to about 0.05% of the dry weight of the flocculant to the finished dry weight of the creped tissue paper produced. The flocculant adsorption capacity is increased by passing the mixture through an in-line mixer...

Embodiment 3

[0320] This example illustrates one embodiment of the invention for making filled tissue paper.

[0321] An aqueous slurry of about 3% by weight eucalyptus fibers was prepared using a conventional pulper. Add Cypro 514 at a rate of 0.02% dry weight relative to the final dry weight of the creped tissue paper into the slurry. The treated slurry is then split into two streams so that the stream which ultimately forms the fabric side surface layer contains twice the amount of material as the stream which ultimately forms the opposite side surface layer. The eucalyptus stream is fed to the paper machine.

[0322] The particulate filler was kaolin clay grade WWFil Slurry(R) manufactured by Dry Branch Kaolin of Dry Branch, GA. It is delivered as a 70% solids slurry through the feed pipe where it is mixed with an anionic flocculant - Accurac 62 - delivered as a 0.3% aqueous dispersion mixed. Accurac 62 It is delivered at a rate corresponding to about 0.5% of the dry weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com