Patents

Literature

39results about How to "Reduce and eliminate vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

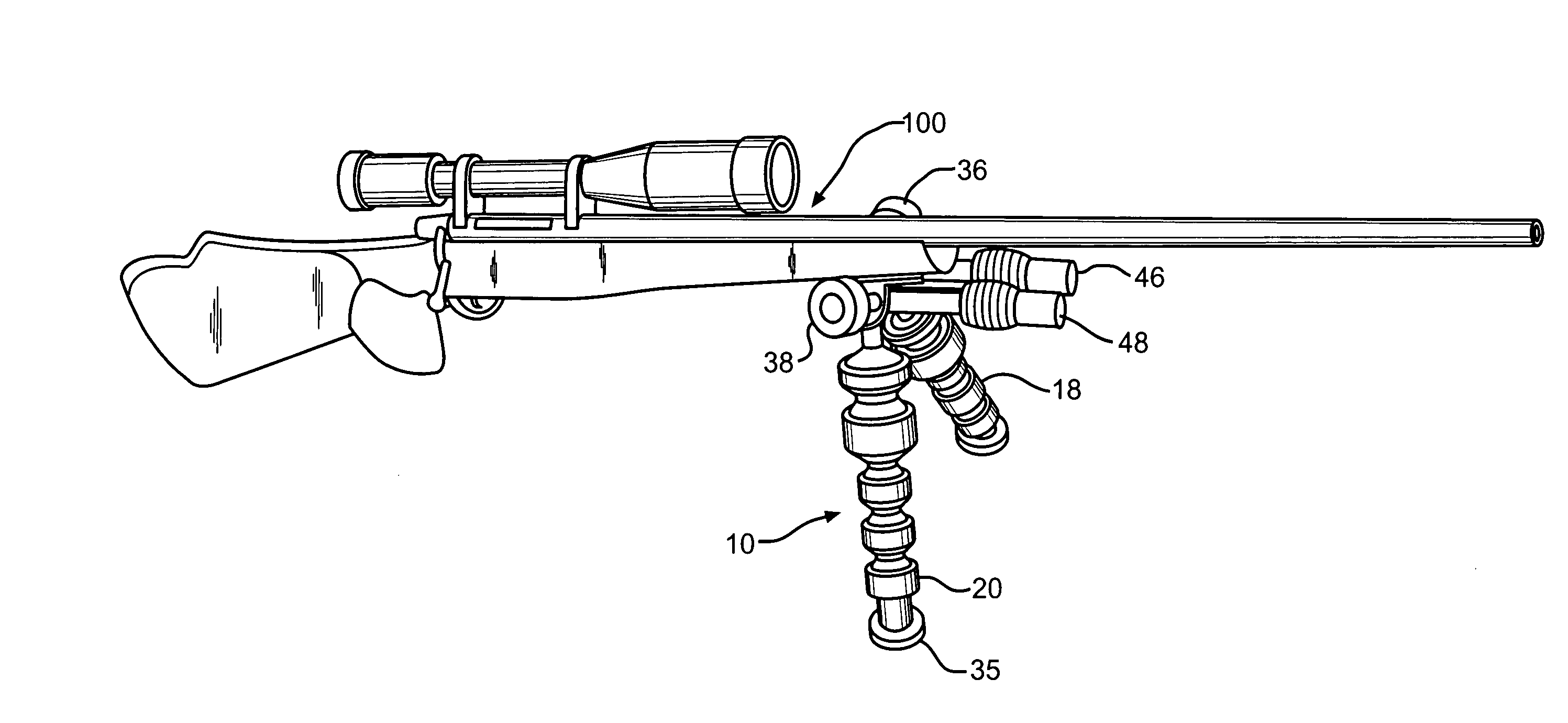

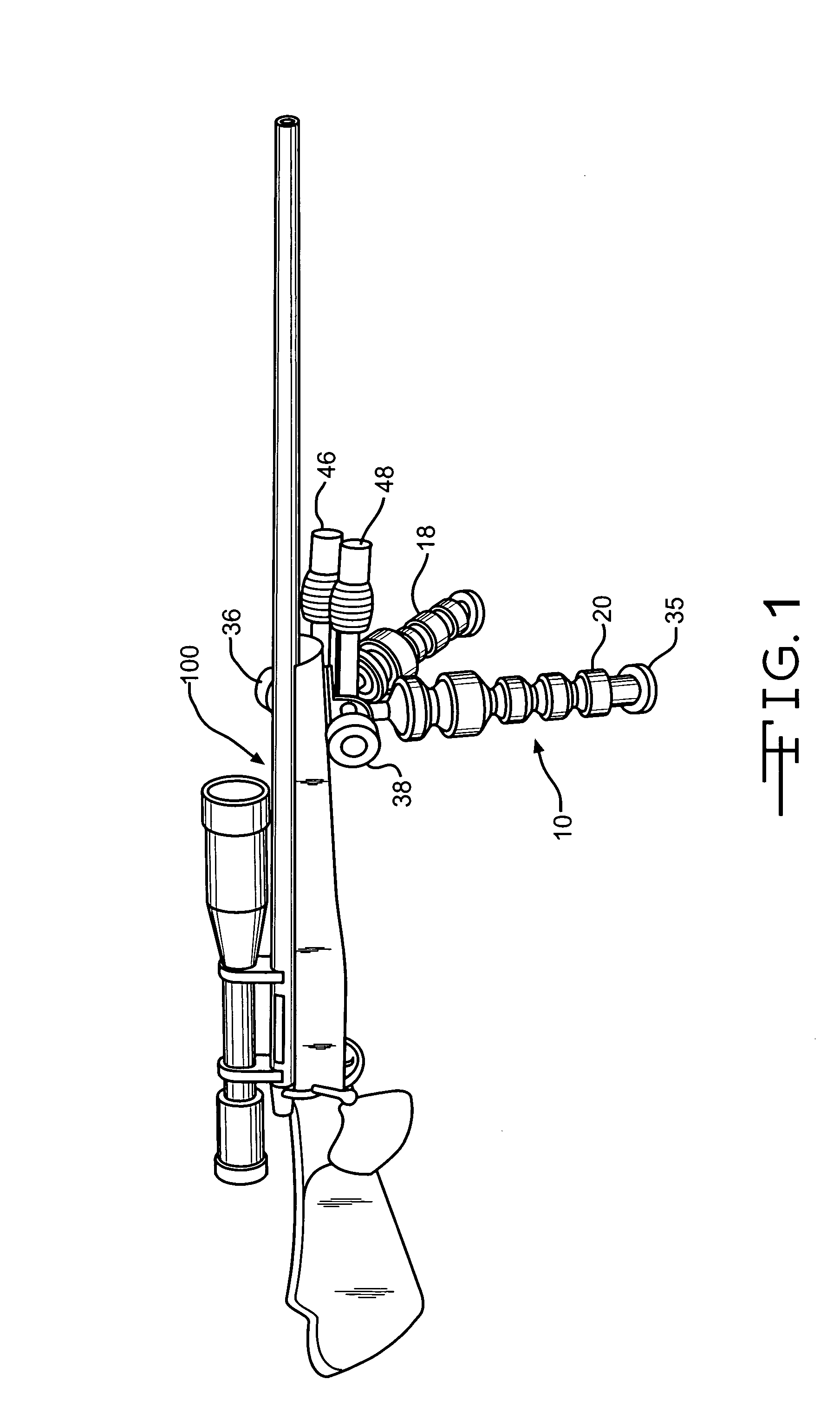

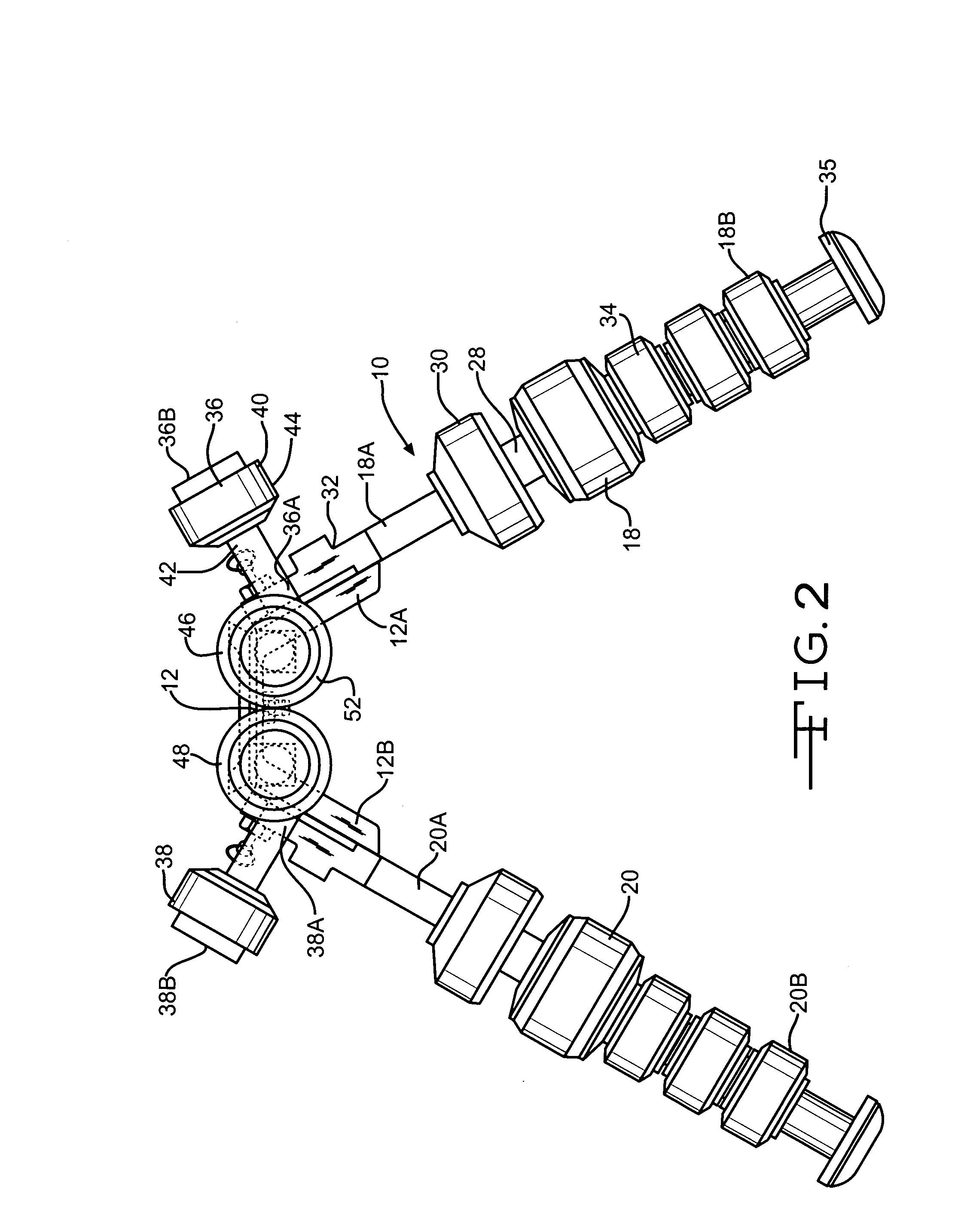

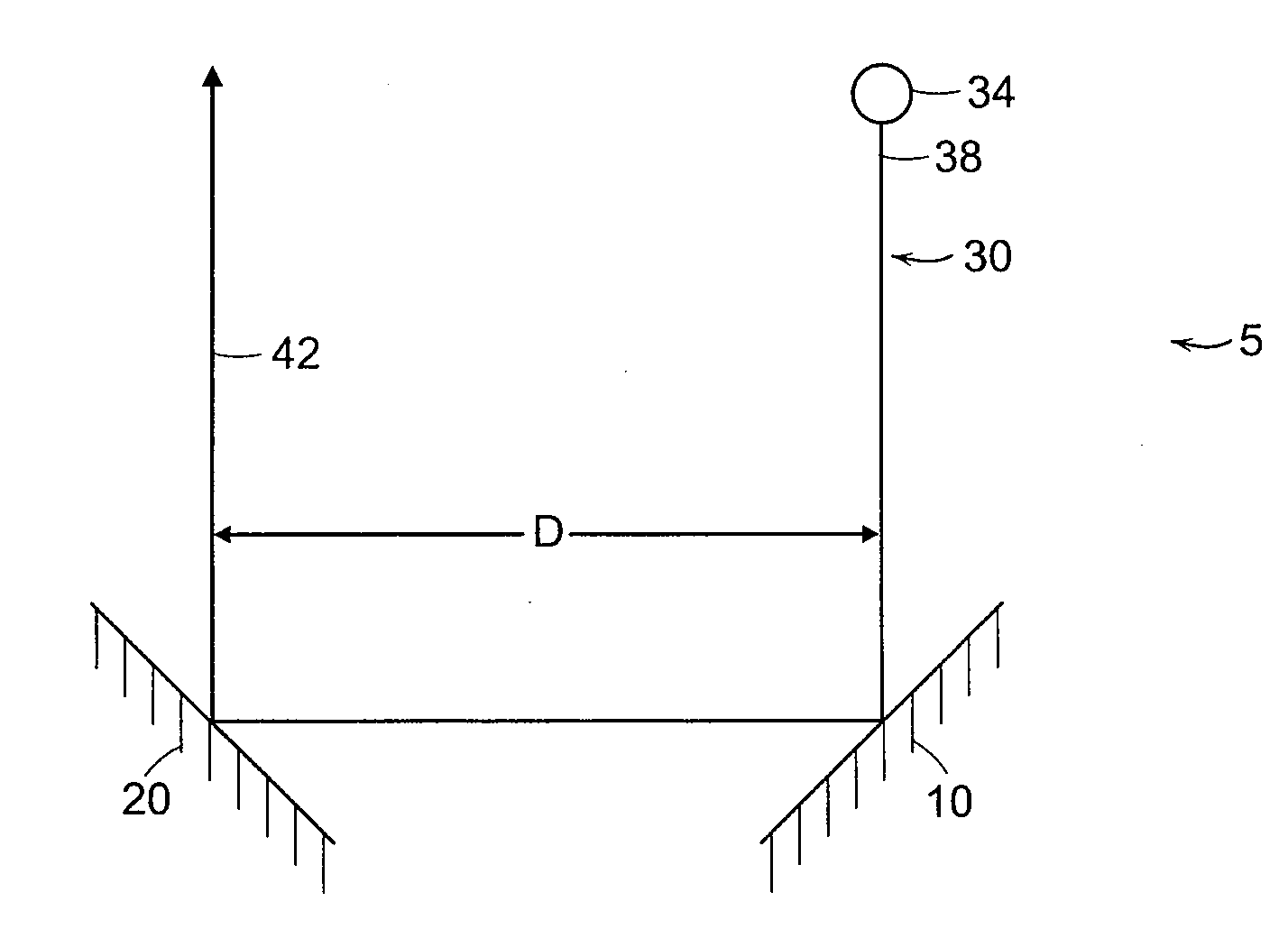

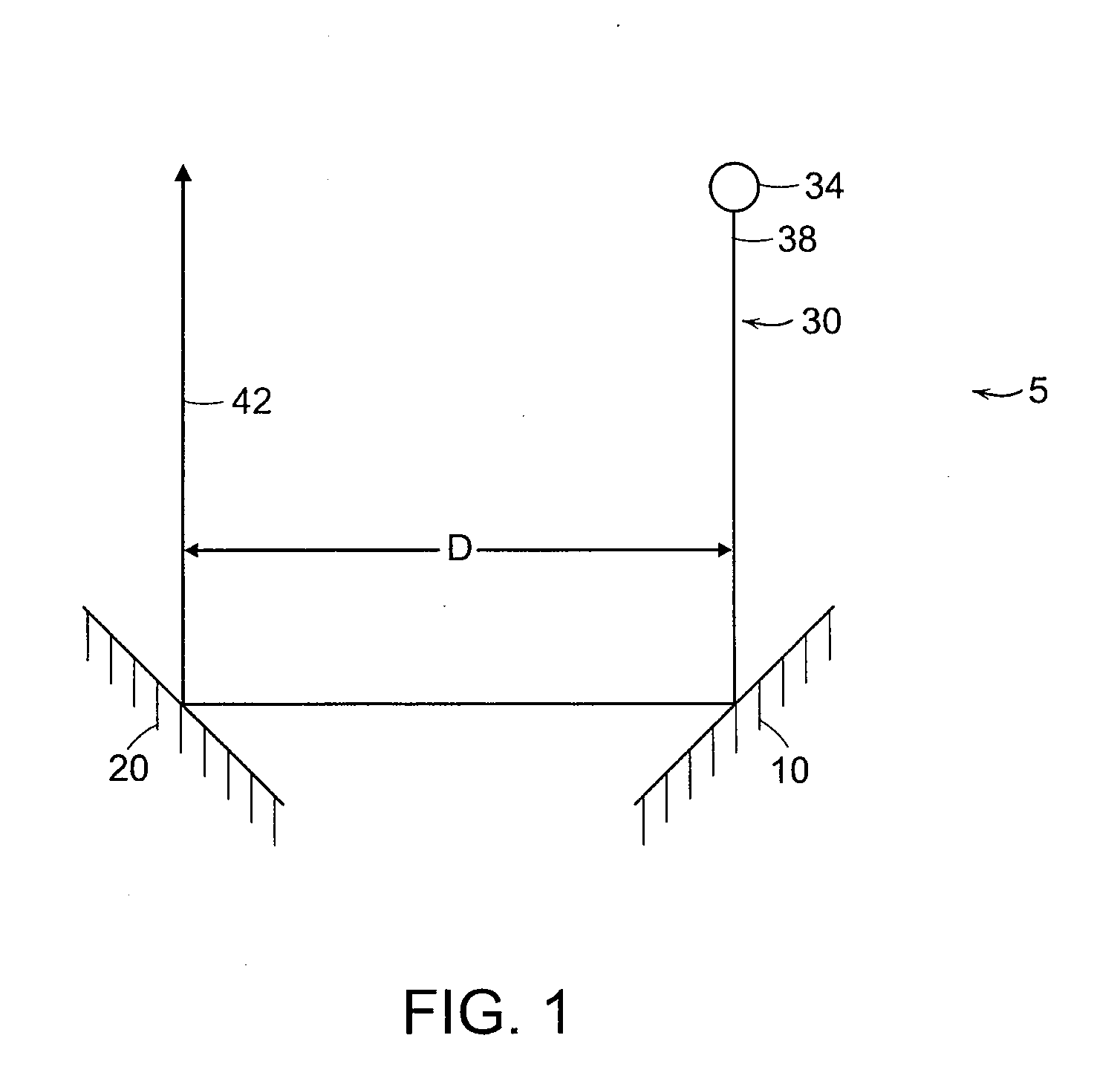

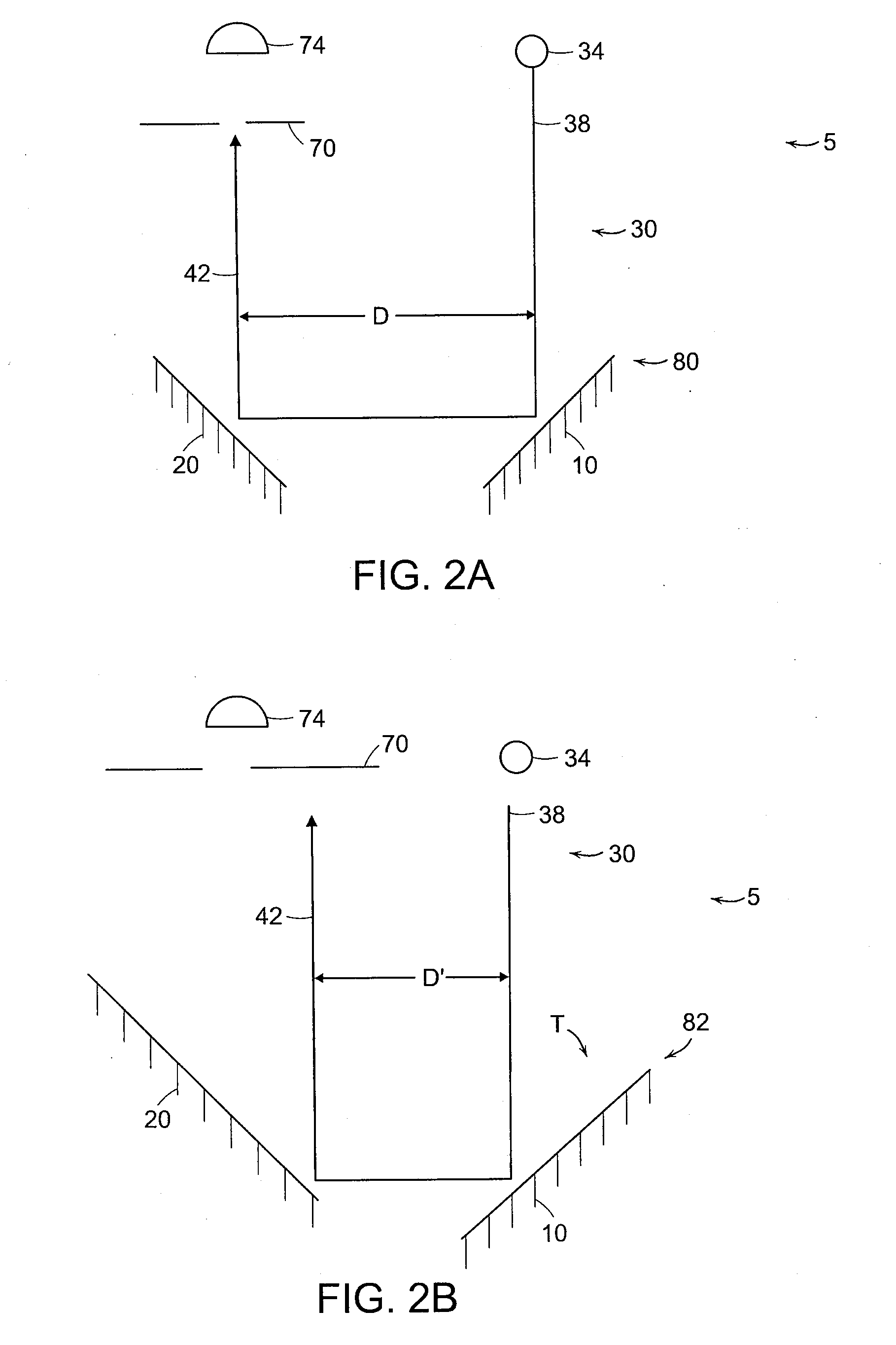

Stabilizing device

ActiveUS7143986B1Simple and accurate operationReduce vibrationStands/trestlesKitchen equipmentEngineeringType selection

Owner:AOA PRODN LLC

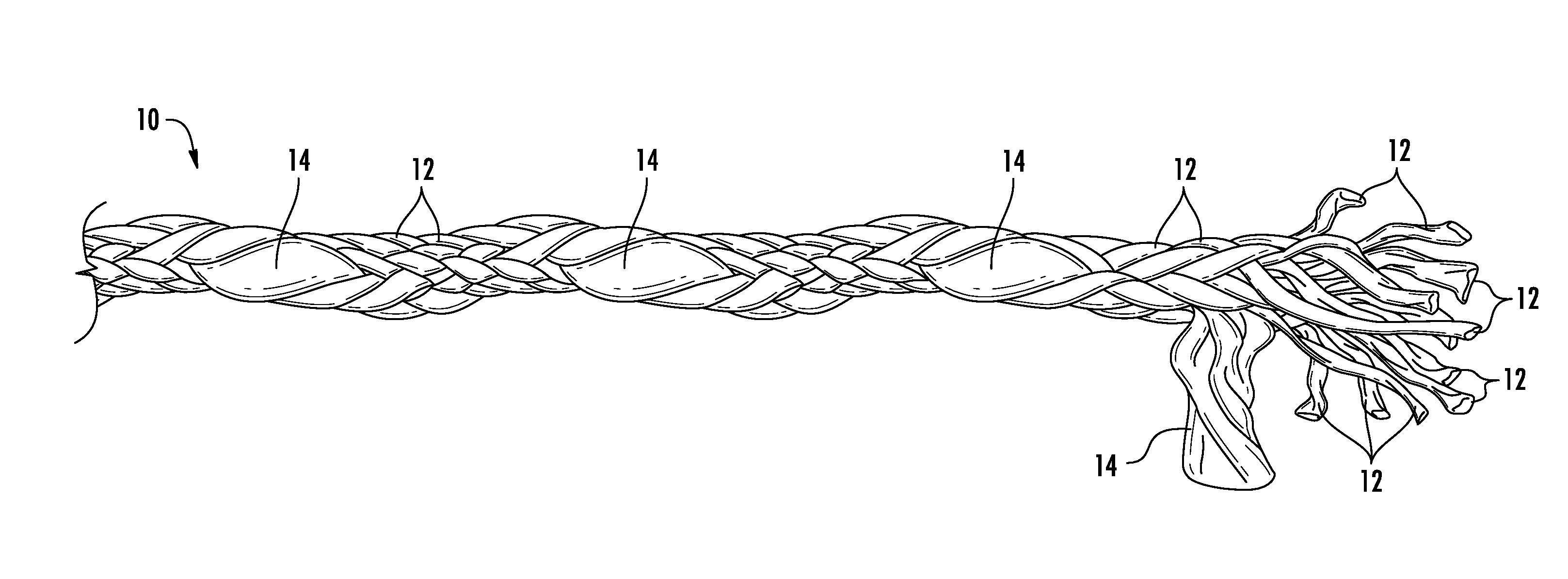

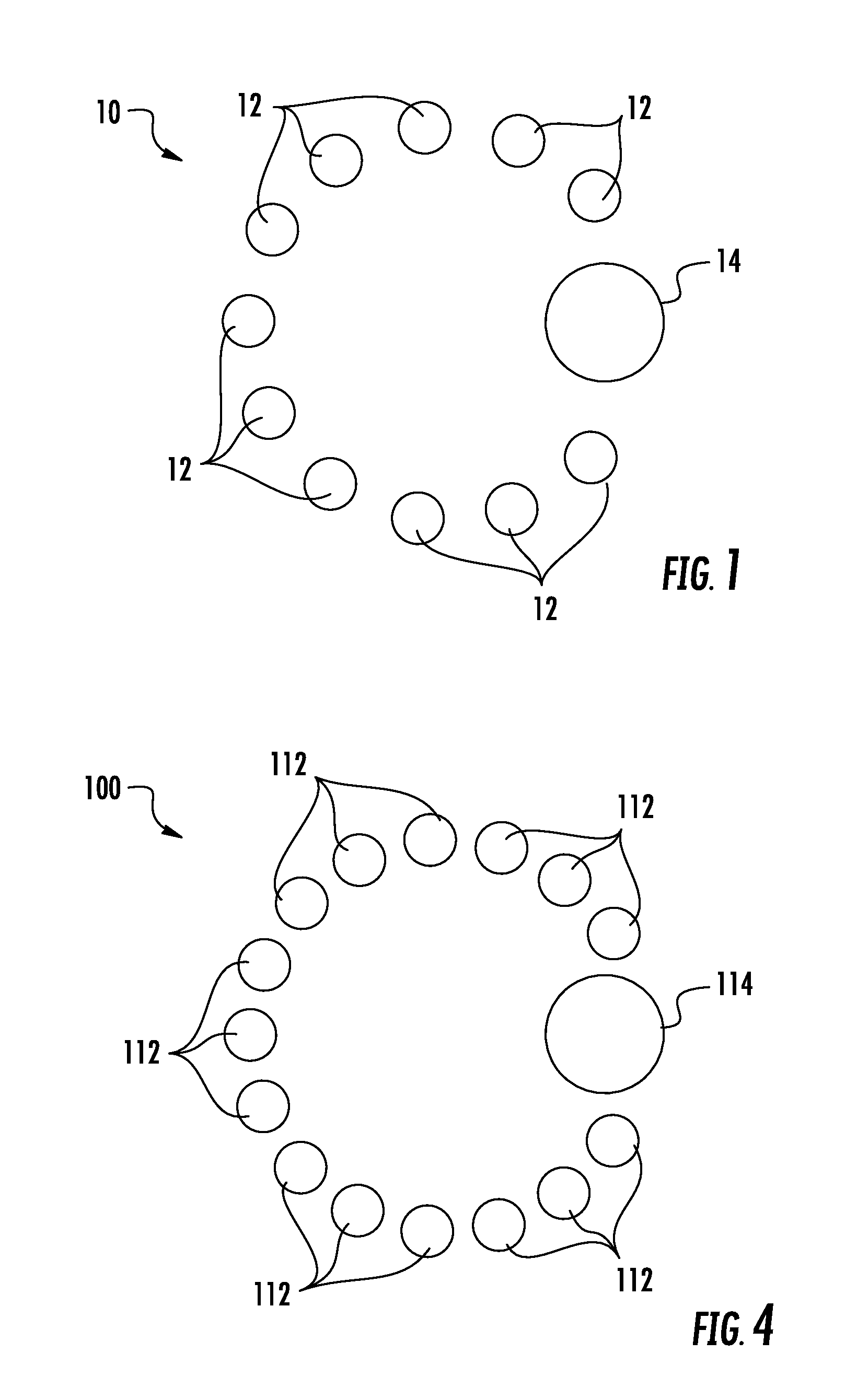

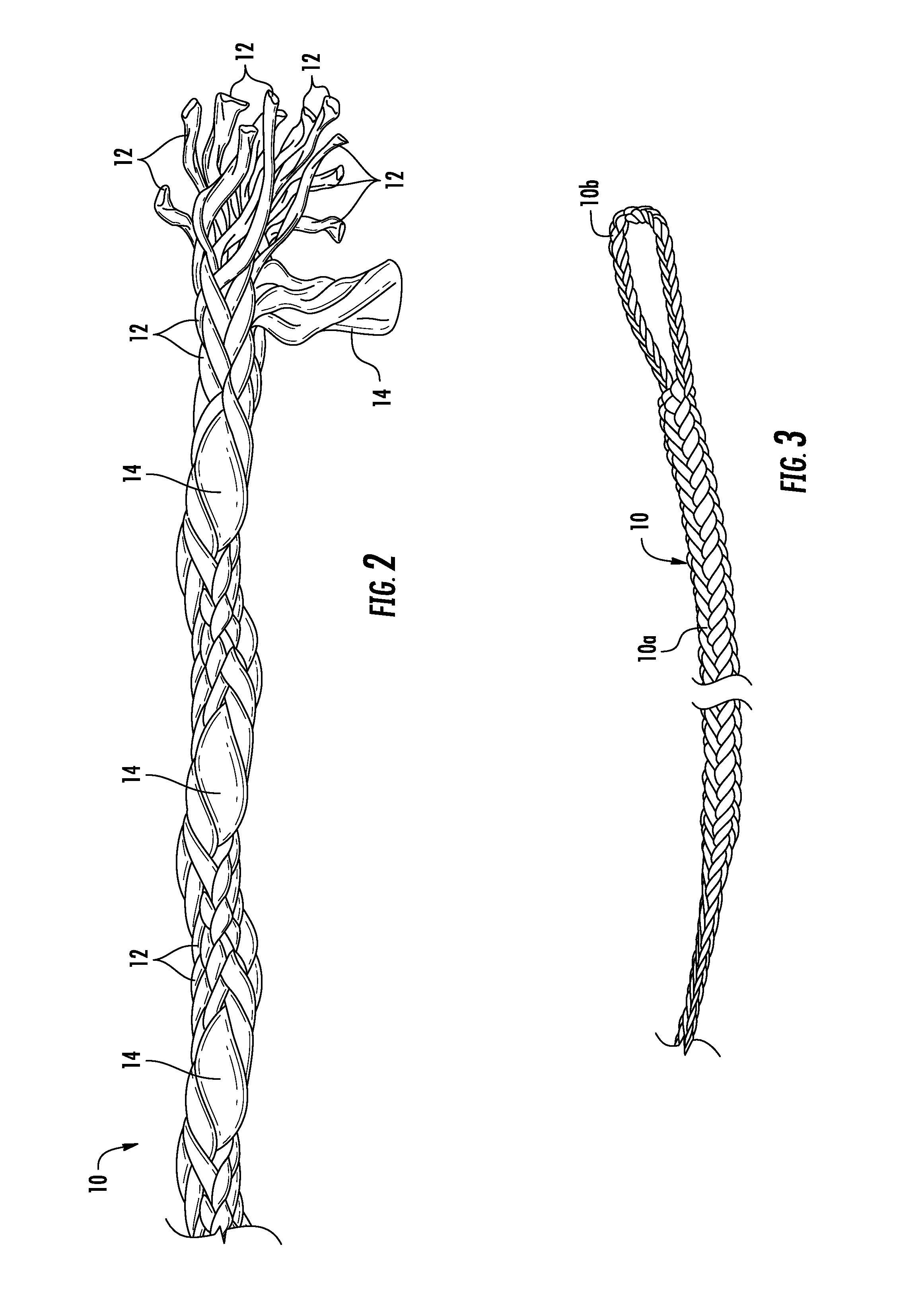

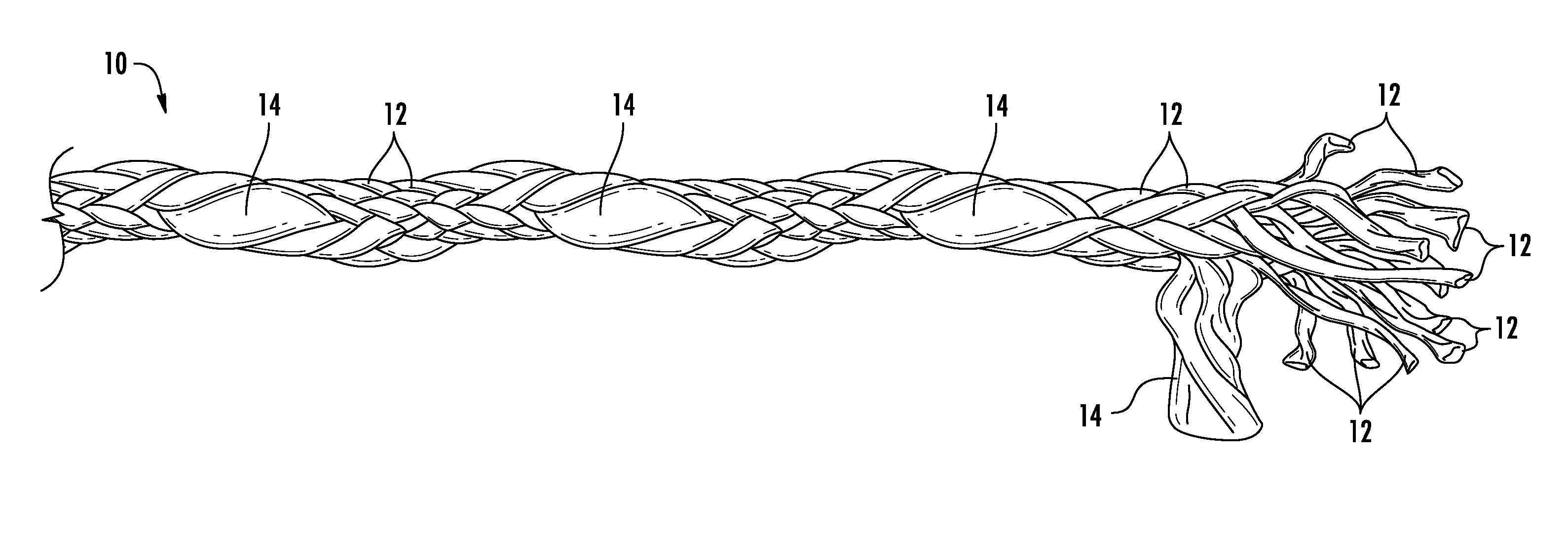

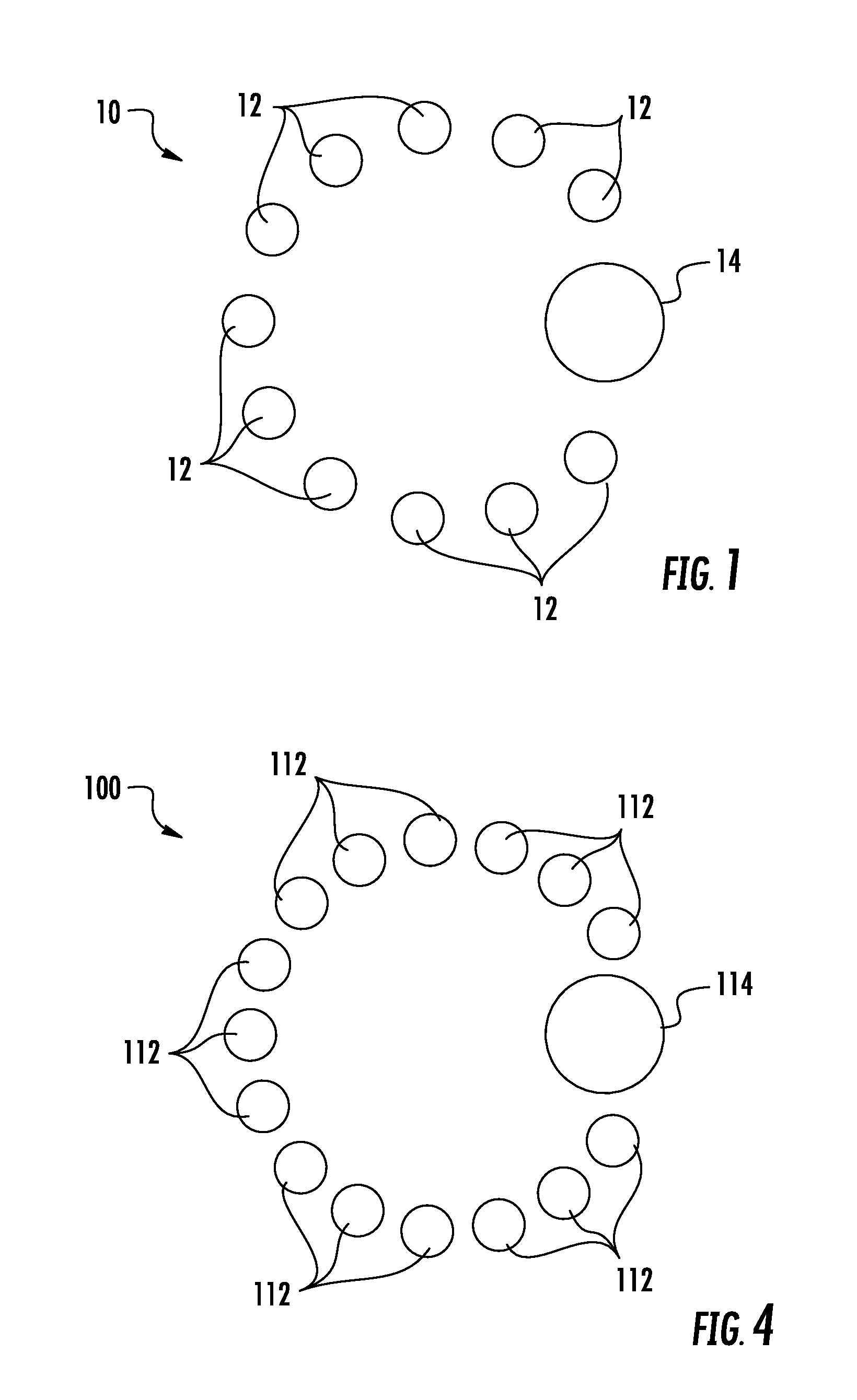

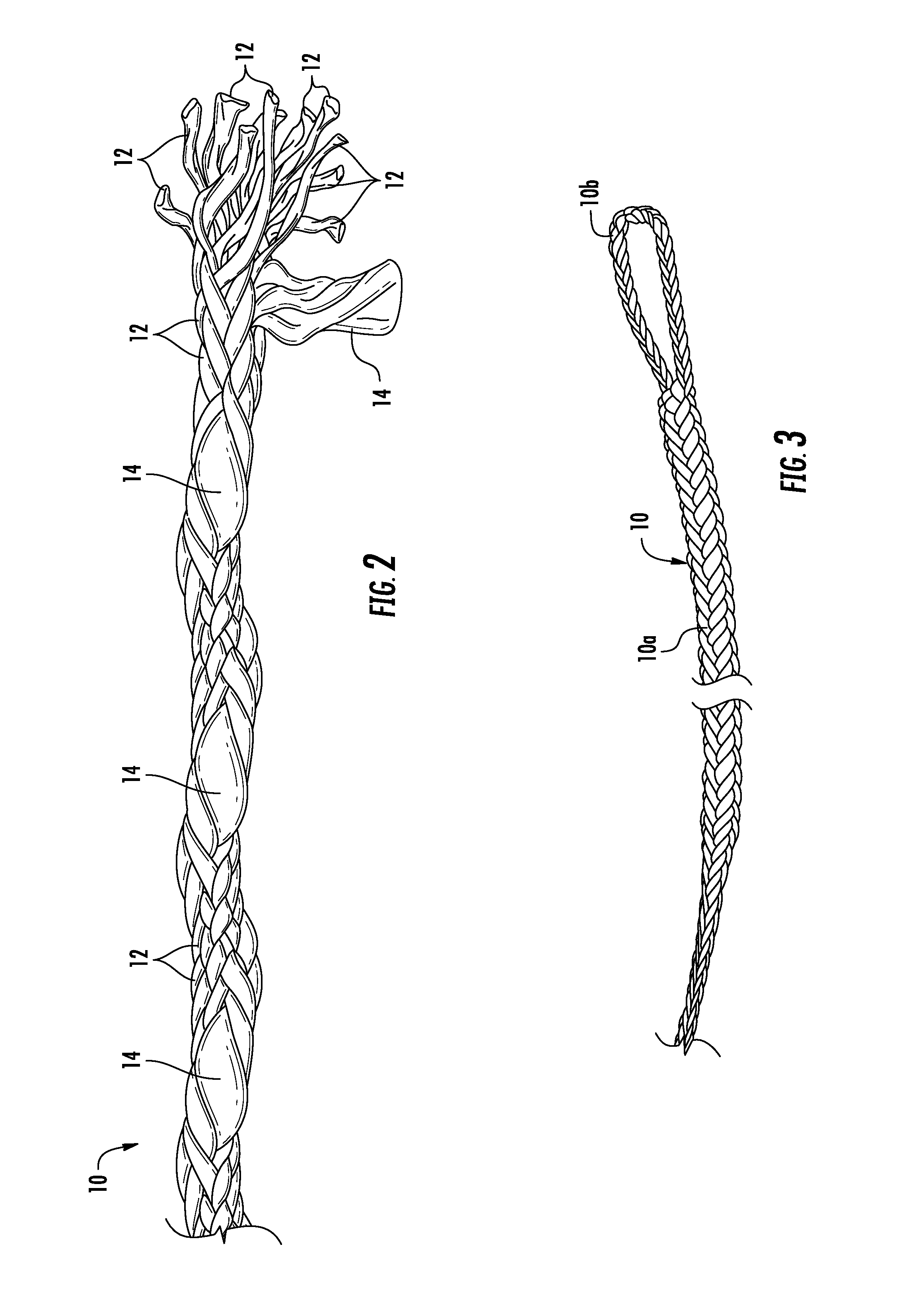

Cord material and methods of using same

ActiveUS20150143981A1Improve drag performance characteristicEliminate vibrationBraidTextile cablesStructural engineeringMechanical engineering

A cord material suitable for use in lined textile structures with a gliding component includes a plurality of uniform strands, and a deviant strand. The deviant strand is different from the uniform strands in some characteristic affecting aerodynamic or hydrodynamic properties of the cord, such as size or surface properties. Each uniform strand can have a substantially equal cross section area, while the deviant strand has a cross section area at least five times greater than one of the uniform strands. The strands can be braided or woven together. A major benefit of the material can be that vibration induced drag is significantly reduced or eliminated in lines made with the material. Another advantage is that lines made from the material can have more consistent, predictable line drag, which can improve the quality of handling.

Owner:A Z CHUTEWORKS L L C

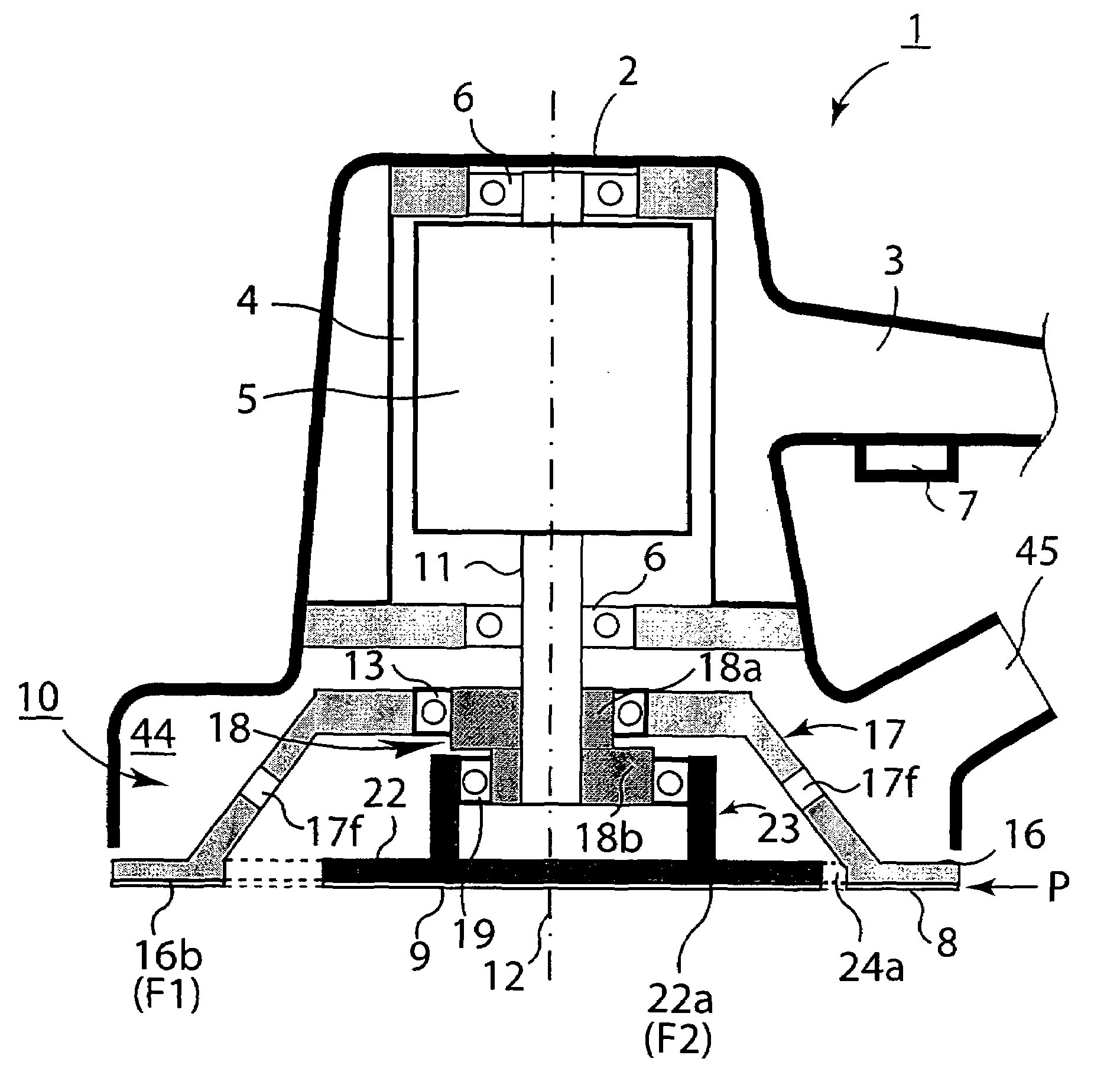

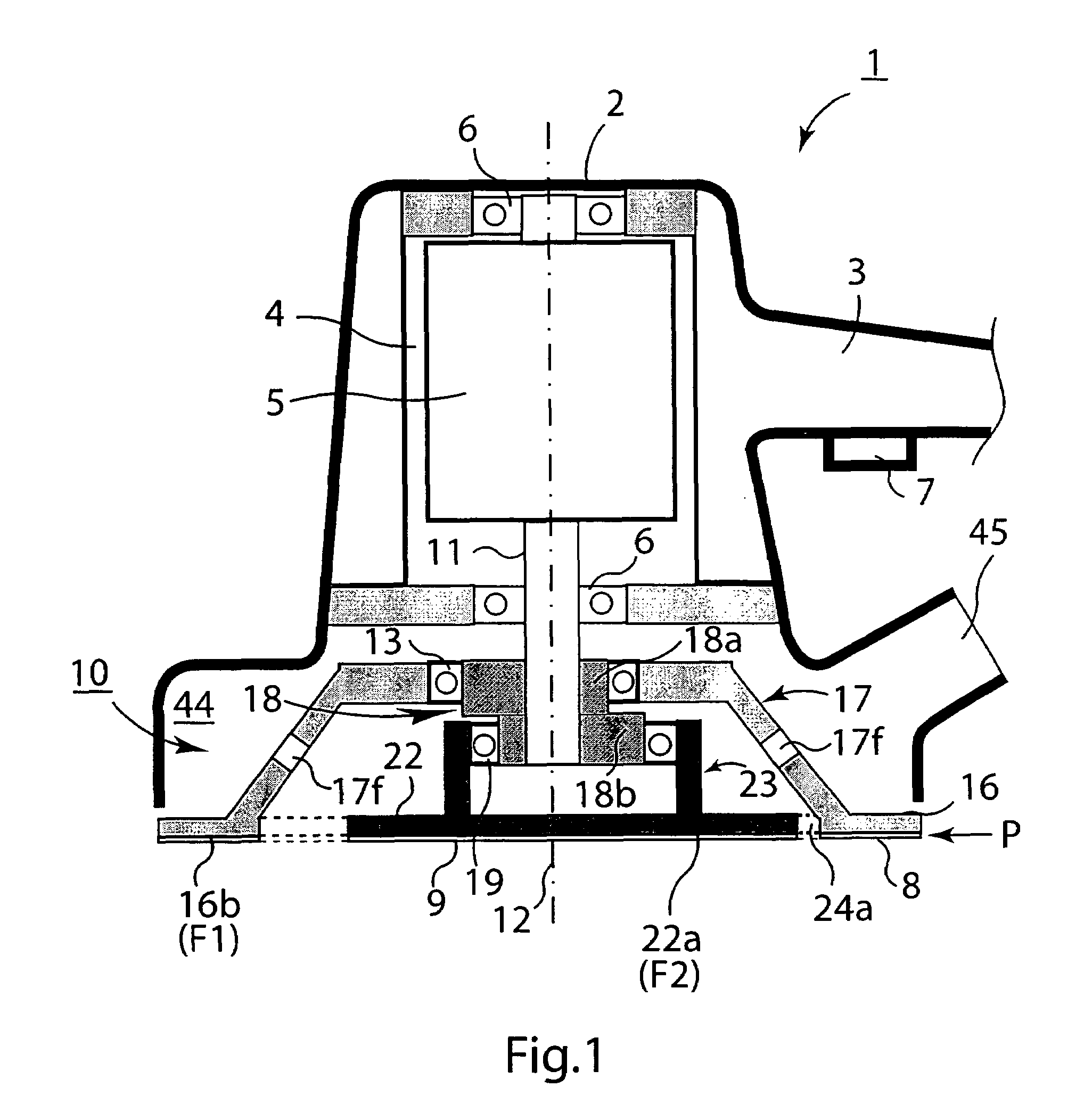

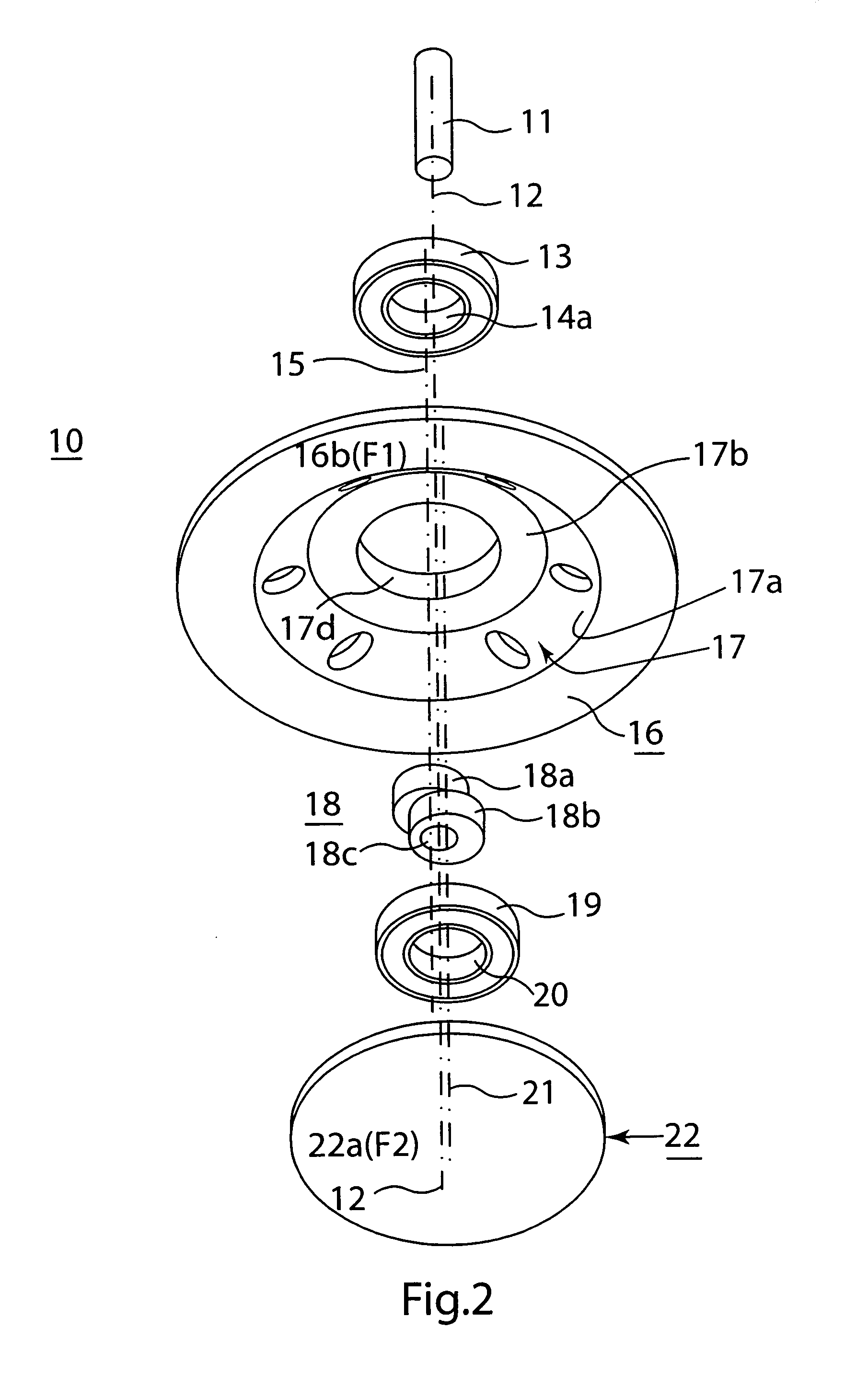

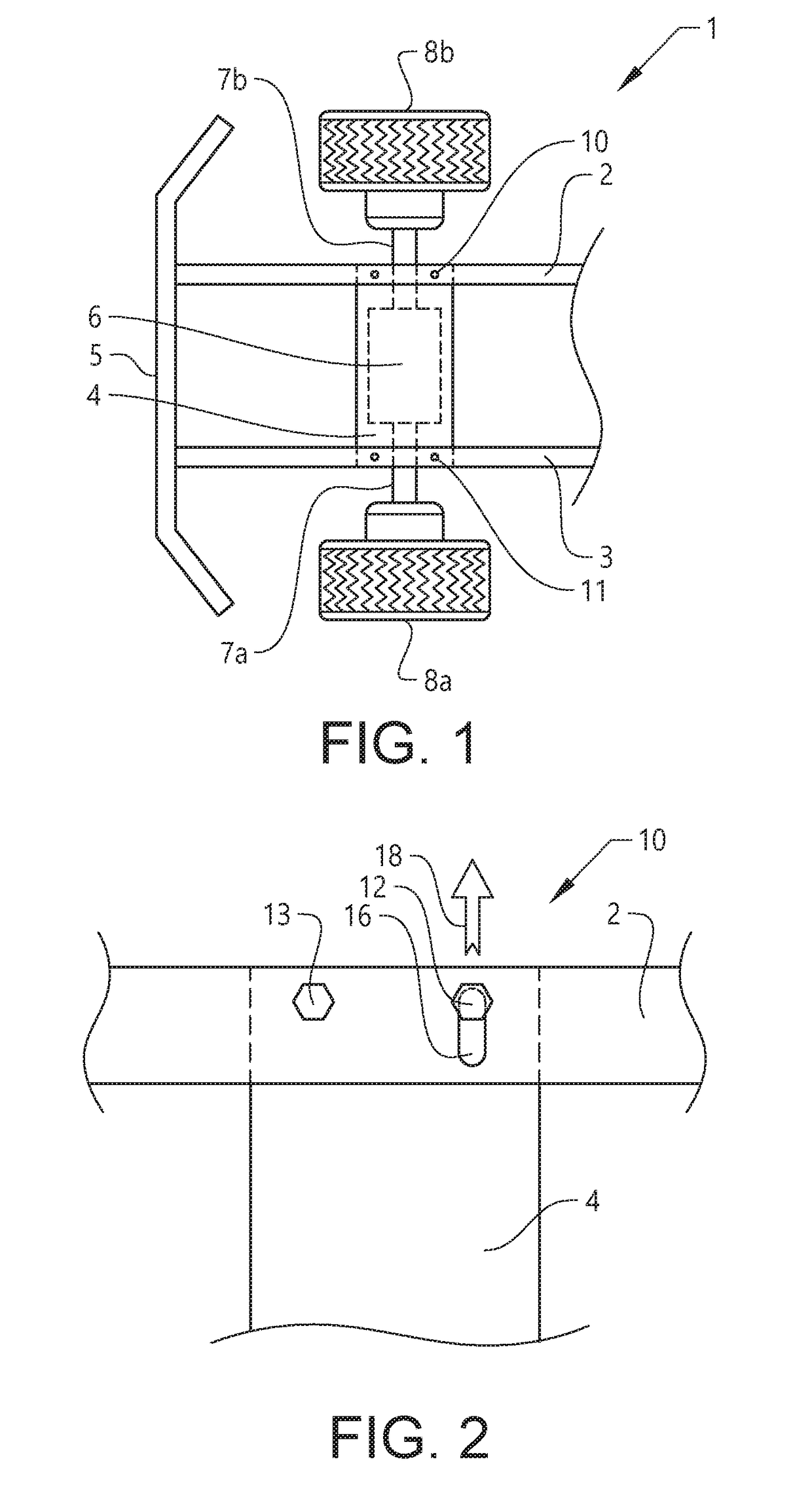

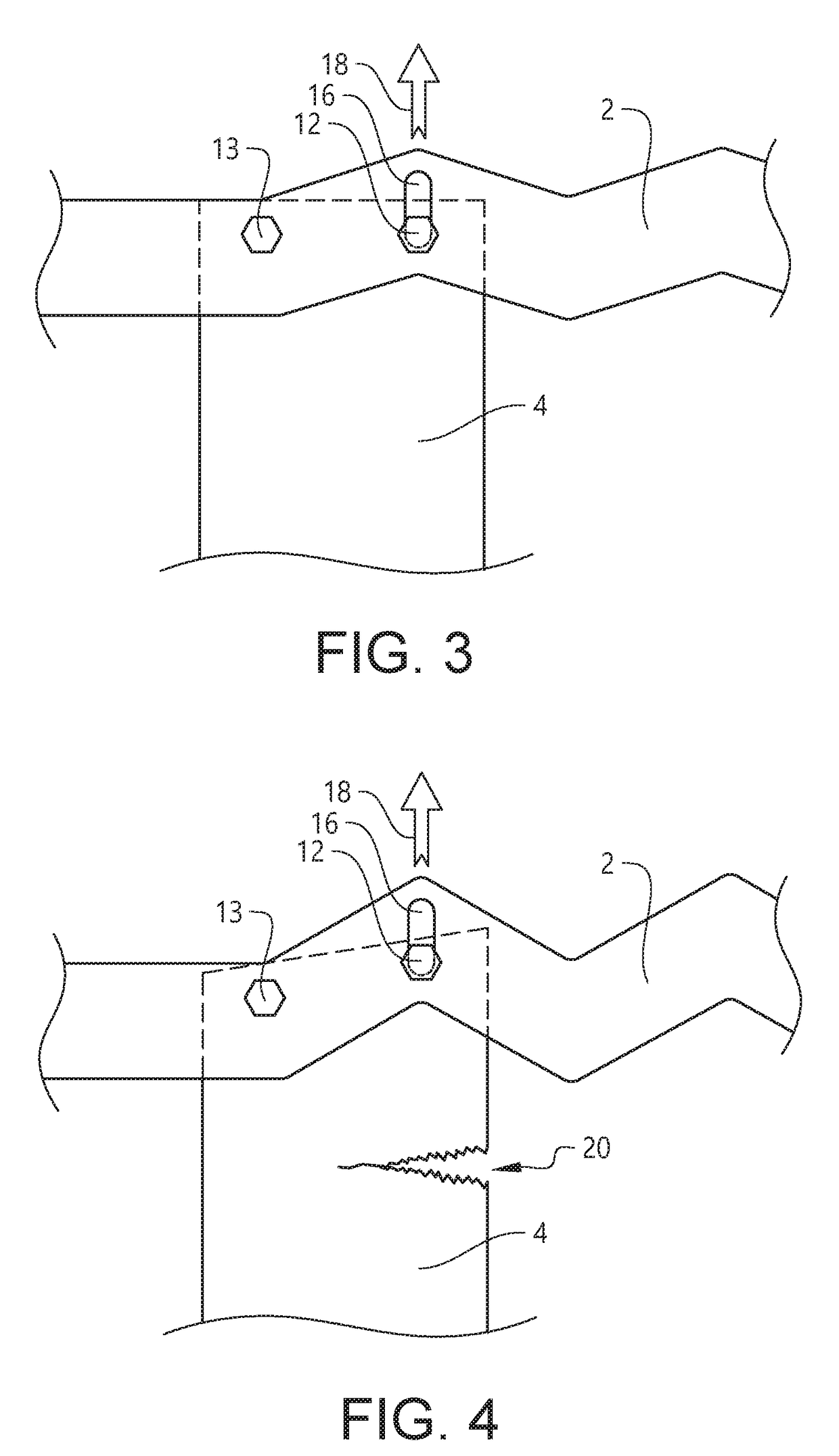

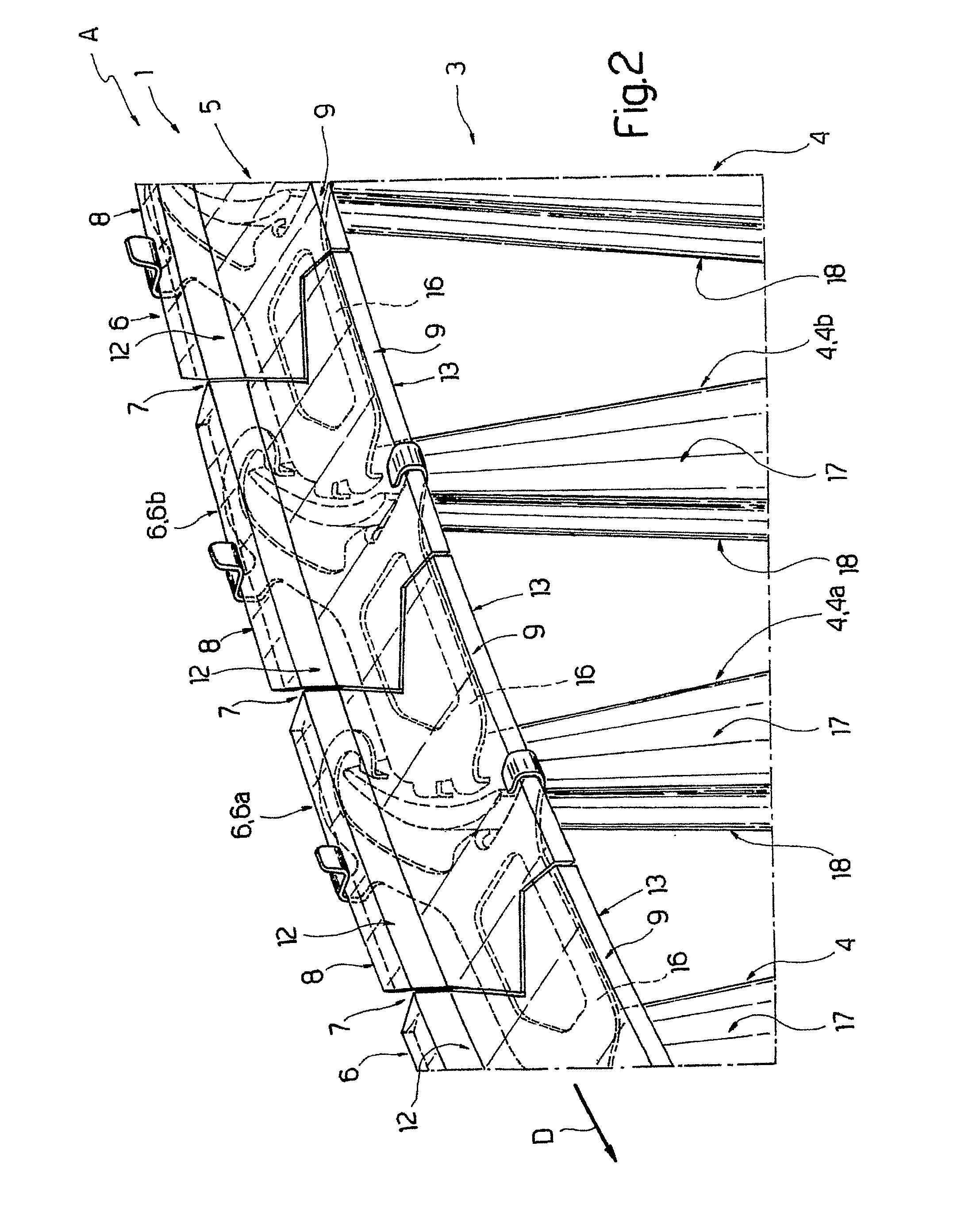

Anti-vibration arrangement

ActiveUS7104873B1Reduce speedReduce rotation speedEdge grinding machinesPortable grinding machinesOut of phaseEngineering

The present invention relates to an anti-vibration arrangement (10) for a power sander (1) which comprises a housing (2), a motor (4) arranged in the housing (2), a rotary drive shaft (11), a first outer or ring-shaped pad surface (16) for attaching a first sanding paper (8) and a second inner or circular pad surface (22) for attaching a second sanding paper (9). The anti-vibration arrangement (10) serves to transfer energy from the motor (4) to the pads (16, 22) with out-of-phase motions to dynamically compensate for inertial and friction forces. For this purpose, twin cams (18a, 18b) are fixed on the rotary drive shaft (11). The cams (18a, 18b) rotate the central axes (15, 21) of the pads (16, 22) about the rotary drive shaft axis (12) with a phase differential of typically 180°. Vibration which would otherwise be transmitted to the rotary drive shaft (11) and from there to the operator of the machine (1) are drastically reduced irrespective of whether or not the operator increases the applied force (1) in order to increase the sanding depth or to speed up the sanding operation.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

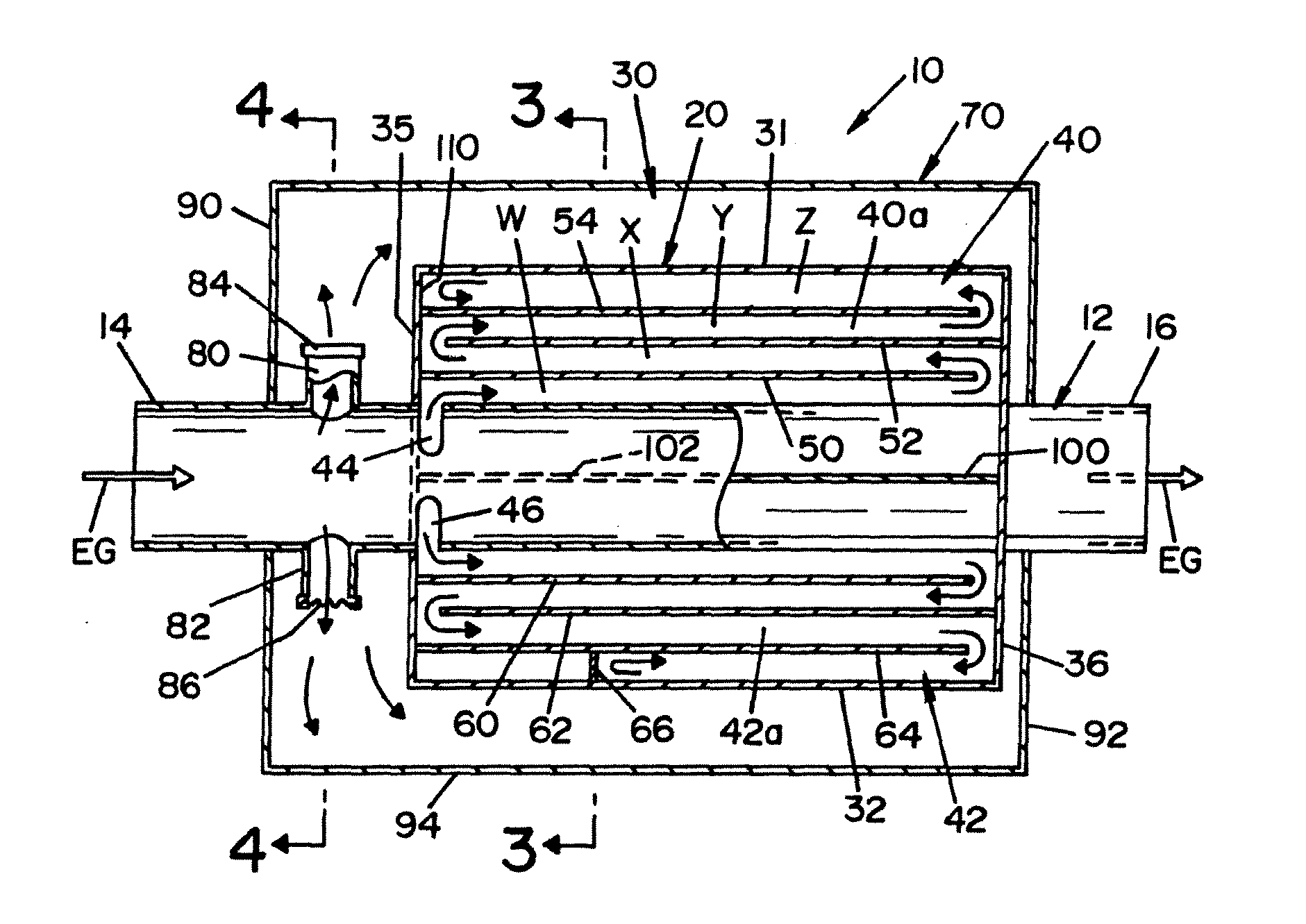

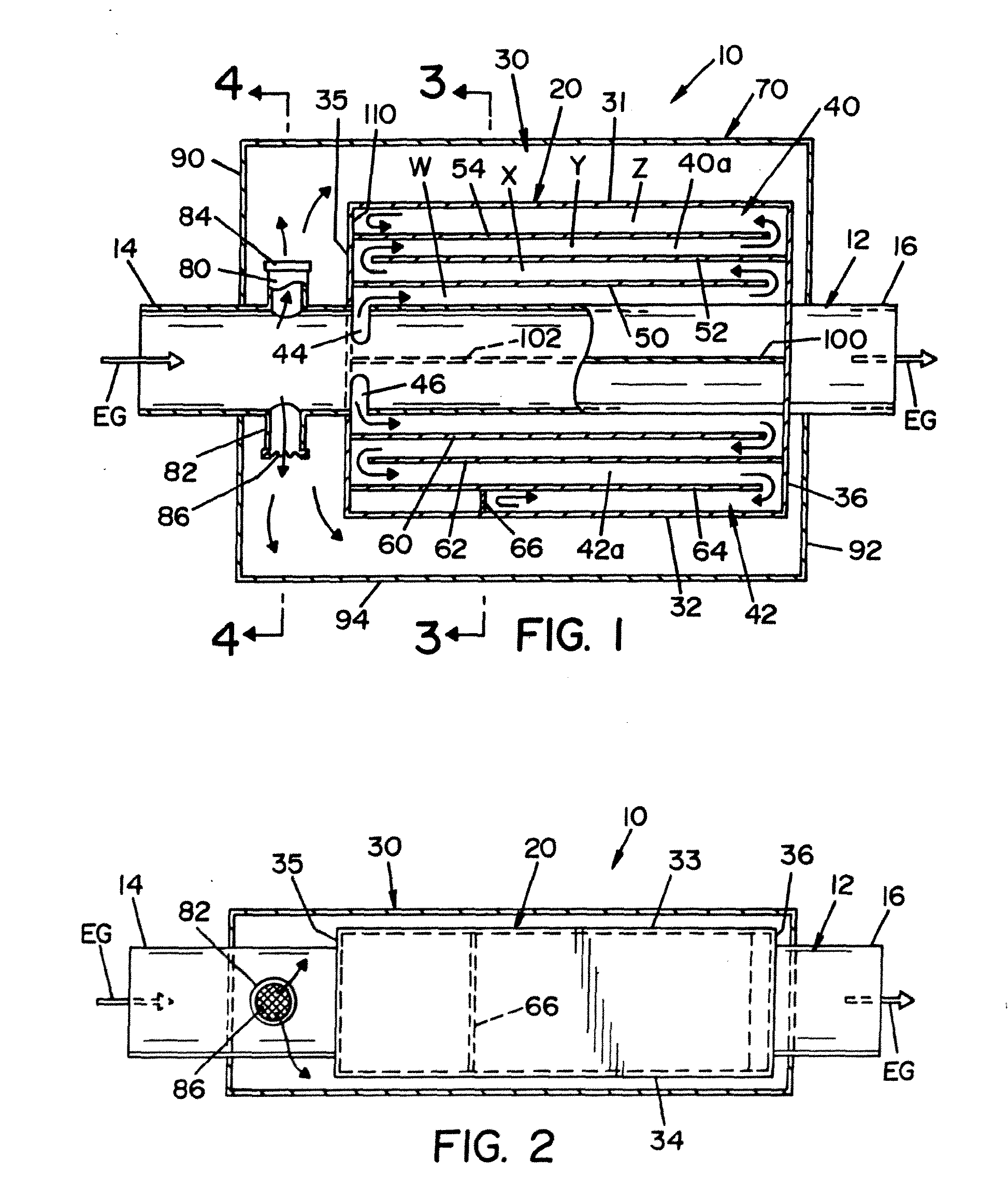

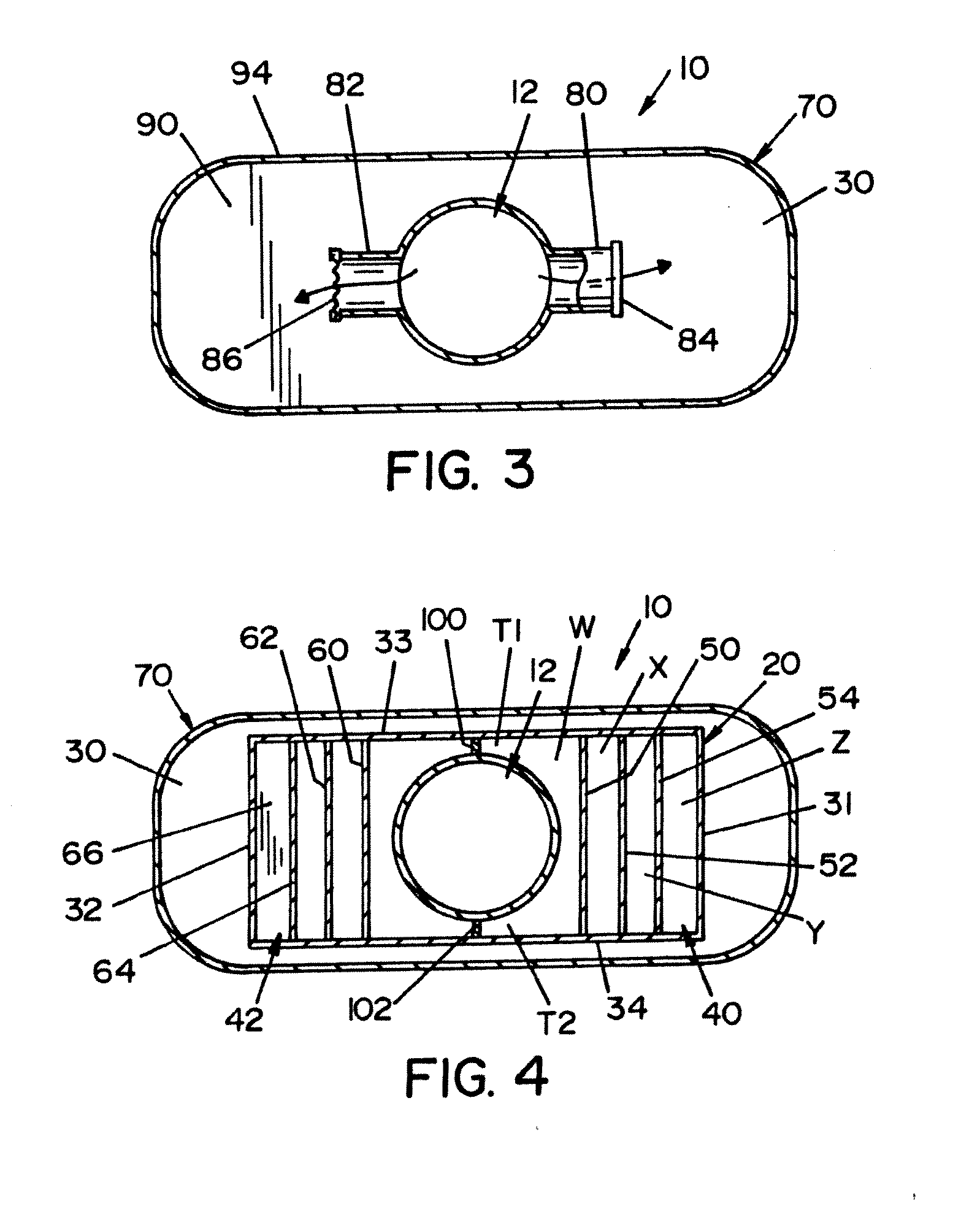

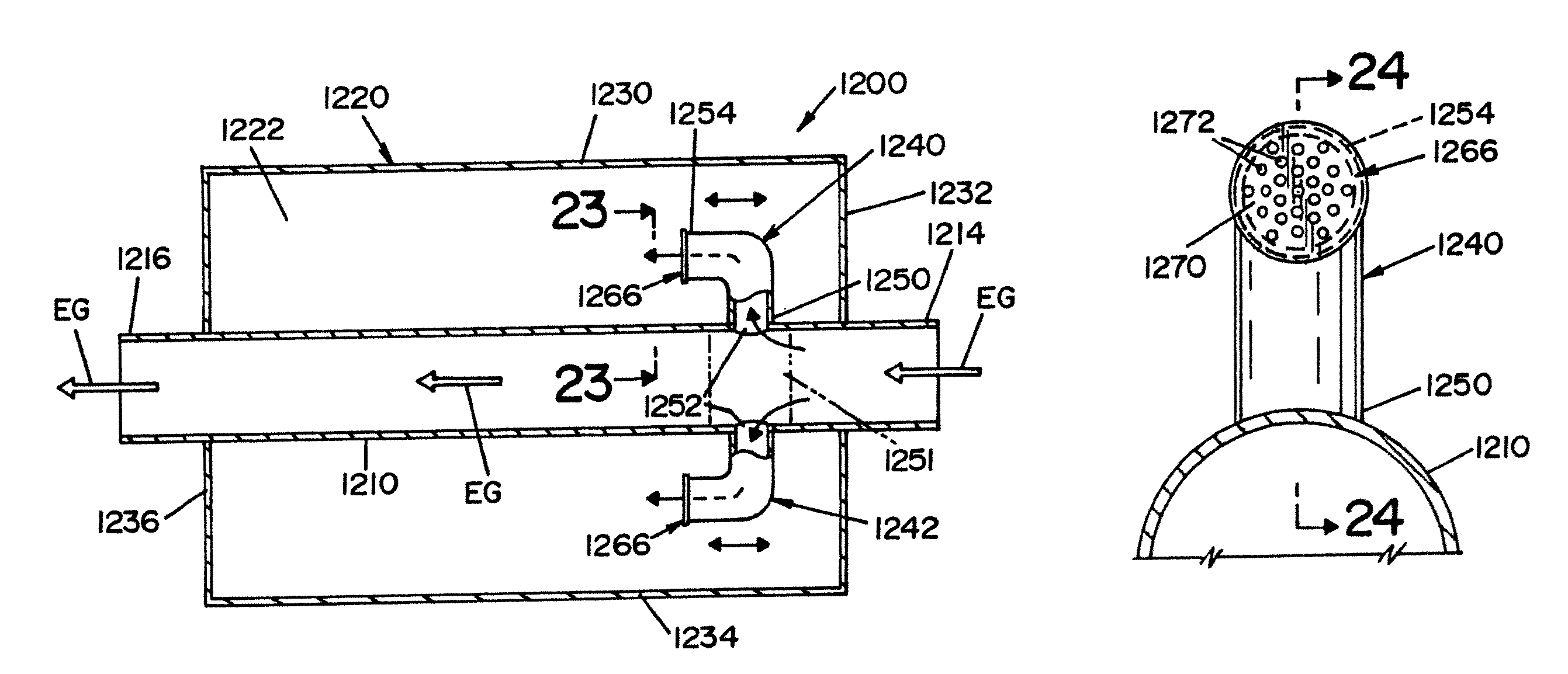

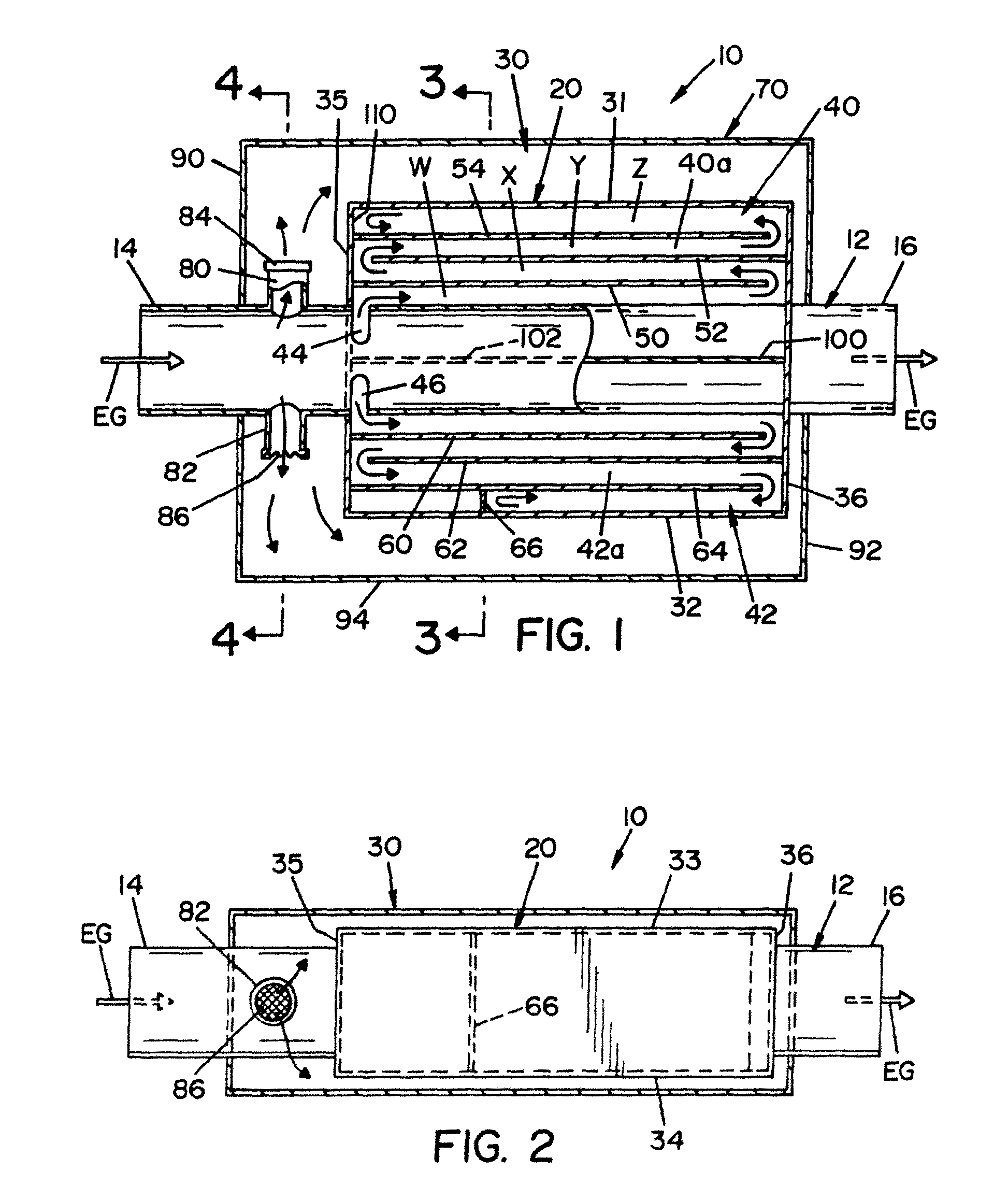

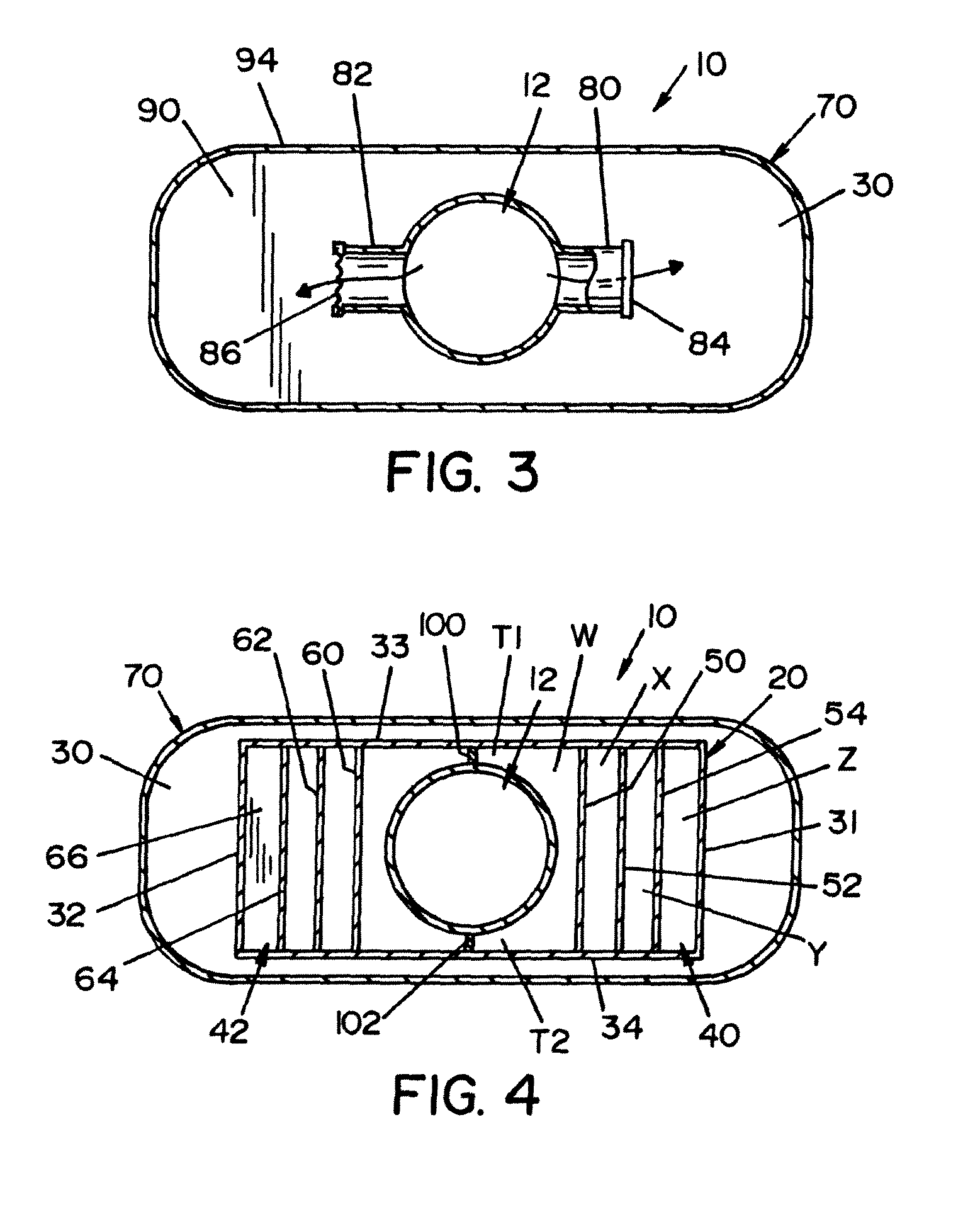

Exhaust muffler

ActiveUS20100270103A1Easy to adjustMaximizes performance characteristicSilencing apparatusMachines/enginesCombustionEngineering

A muffler for reducing the sounds of combustion gases exhausted from an internal combustion engine including an elongated fluid passage extending between an inlet and an outlet such that the outlet is in fluid communication with the inlet. Further, the inlet being connectable with the gases exhausted from the engine and the outlet being connectable with the atmosphere. The muffler further including an outer tank surrounding the passage and a tubular connector having a first end in fluid connection with the passage and a second end in fluid connection with the tank such that the connector produces a fluid connection between the passage and the tank. The connectors having a perforated resistance plate to restrict the fluid flow between said passage and said sound chamber thereby reducing the severity of the sound or fluid pulses entering and exiting said sound chamber, perforations in said perforated plate forming an open portion of said plate and said open portion being less than 60 percent.

Owner:TMG PERFORMANCE PRODS

Exhaust muffler

ActiveUS7942239B2Easy to adjustMaximizes performance characteristicSilencing apparatusMachines/enginesCombustionEngineering

A muffler for reducing the sounds of combustion gases exhausted from an internal combustion engine including an elongated fluid passage extending between an inlet and an outlet such that the outlet is in fluid communication with the inlet. Further, the inlet being connectable with the gases exhausted from the engine and the outlet being connectable with the atmosphere. The muffler further including an outer tank surrounding the passage and a tubular connector having a first end in fluid connection with the passage and a second end in fluid connection with the tank such that the connector produces a fluid connection between the passage and the tank. The connectors having a perforated resistance plate to restrict the fluid flow between said passage and said sound chamber thereby reducing the severity of the sound or fluid pulses entering and exiting said sound chamber, perforations in said perforated plate forming an open portion of said plate and said open portion being less than 60 percent.

Owner:TMG PERFORMANCE PRODS

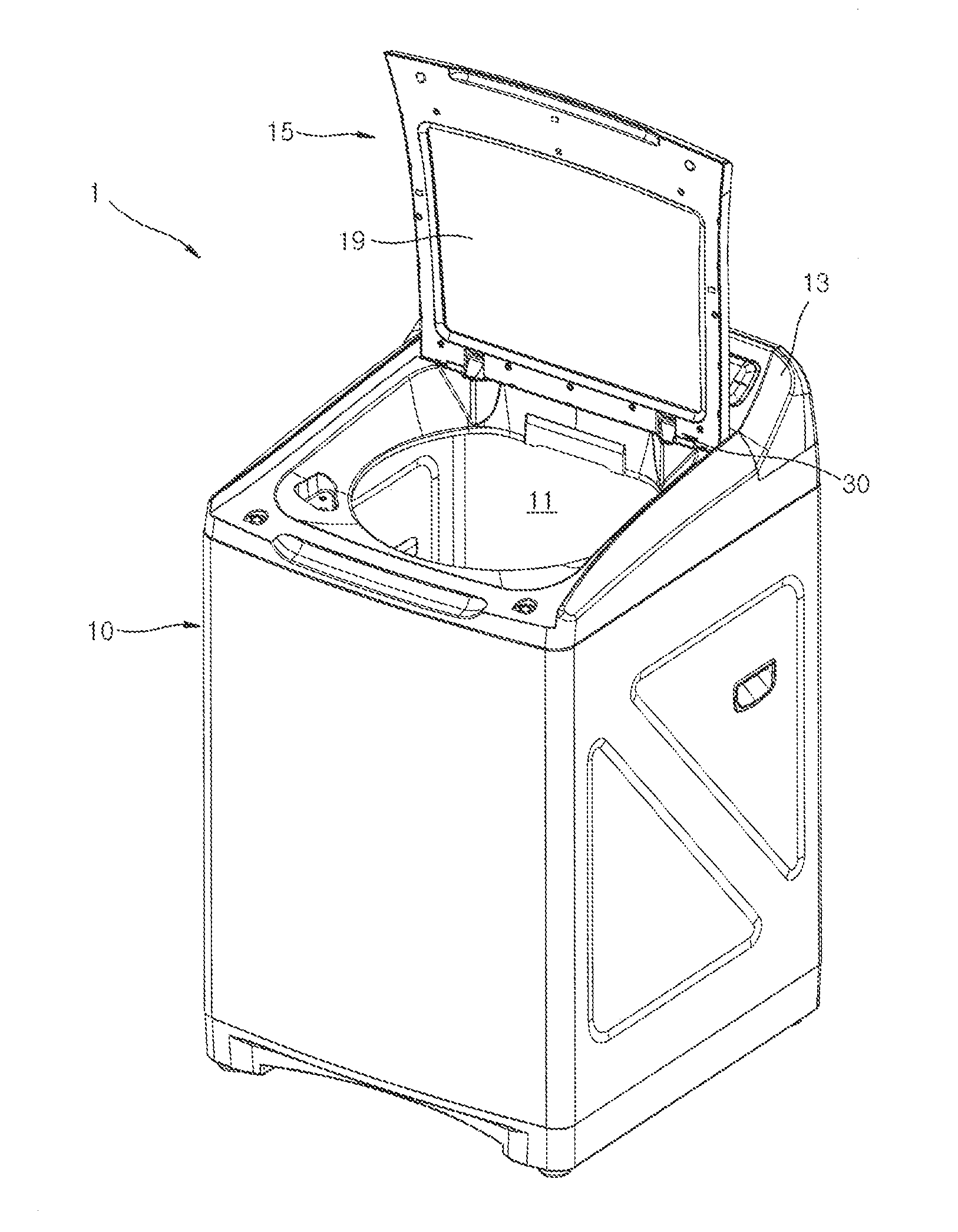

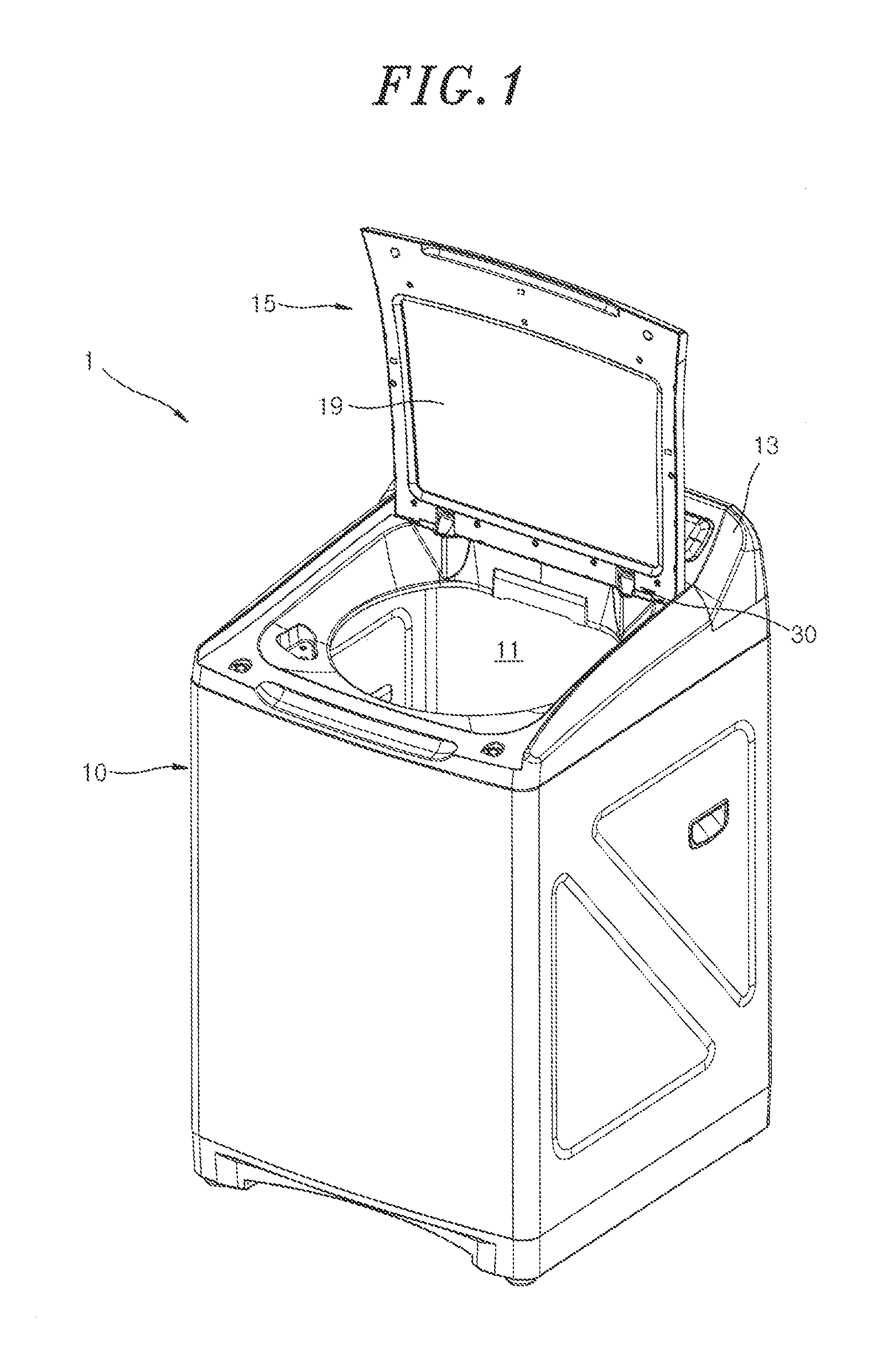

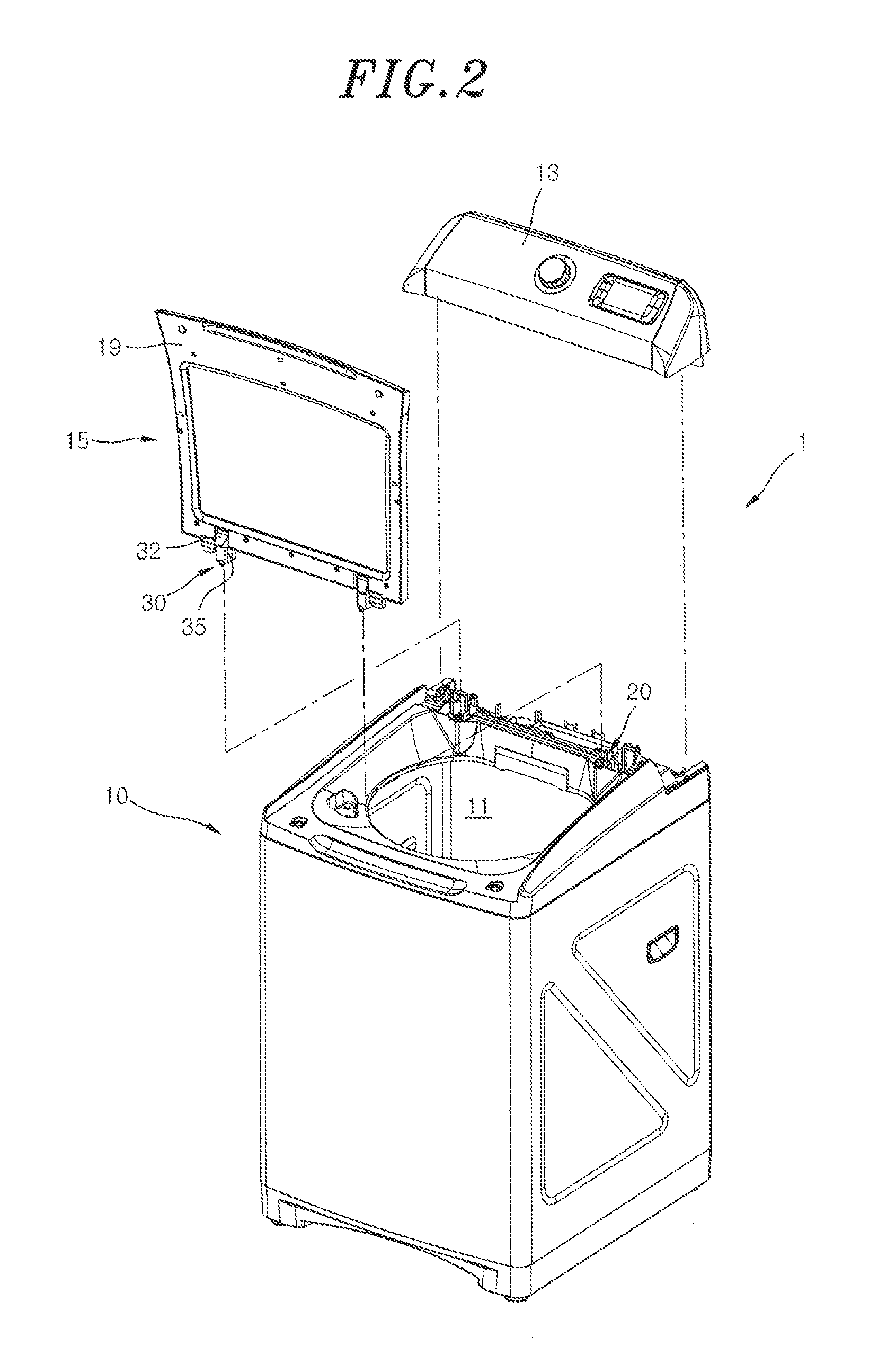

Washing machine

ActiveUS20150008808A1Shorten speedReduce and eliminate vibrationWash-standsKitchenware cleanersJoint componentShock absorber

A washing machine including an attachment groove on or in a top portion or surface of a cabinet; a joint member coupled to the cabinet and in the attachment groove; a door configured to open and close an inlet of the cabinet, and a damper connected to the joint member and configured to adjust or control a rotational speed of the door.

Owner:DONGBU DAEWOO ELECTRONCIS CORP

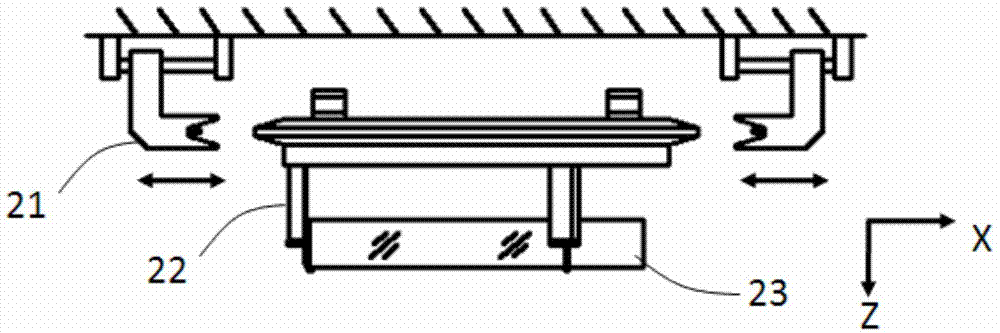

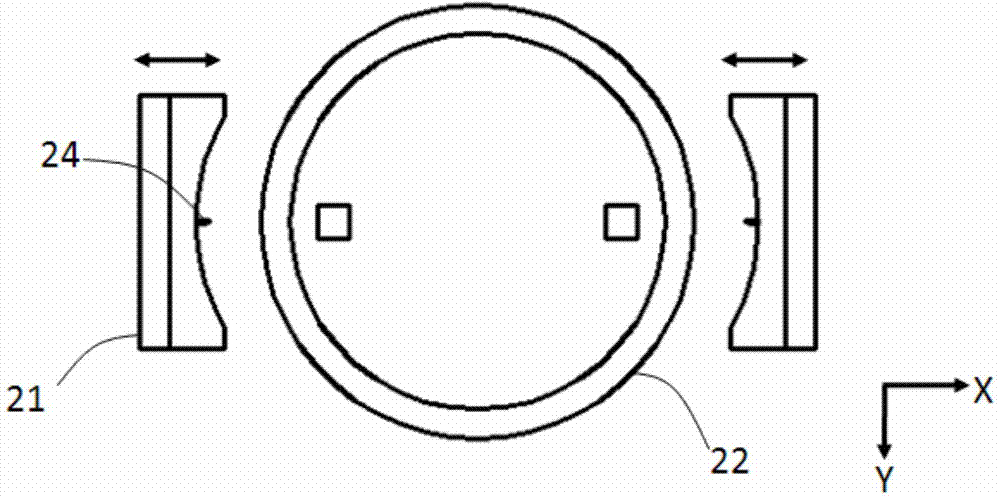

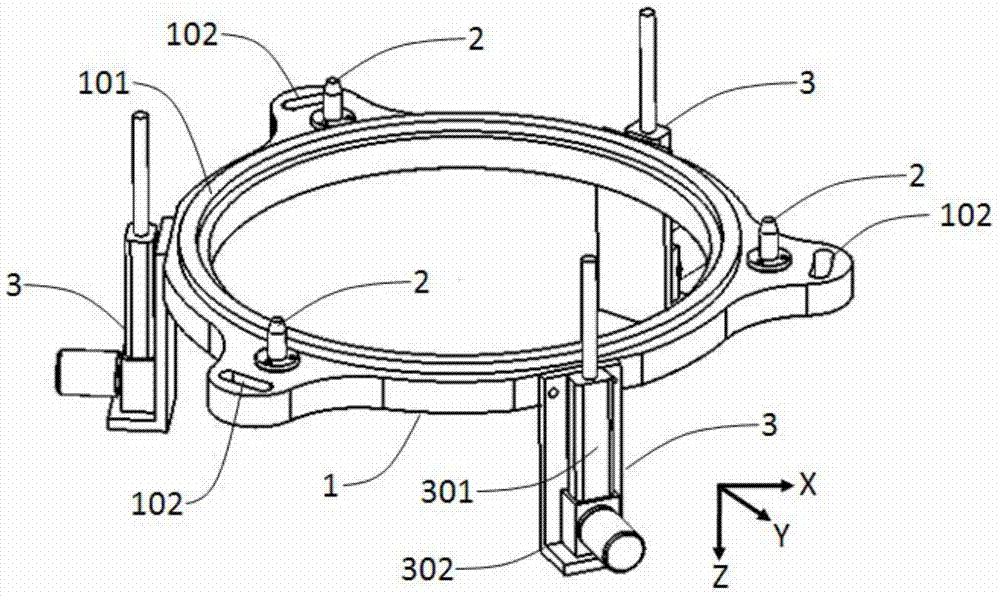

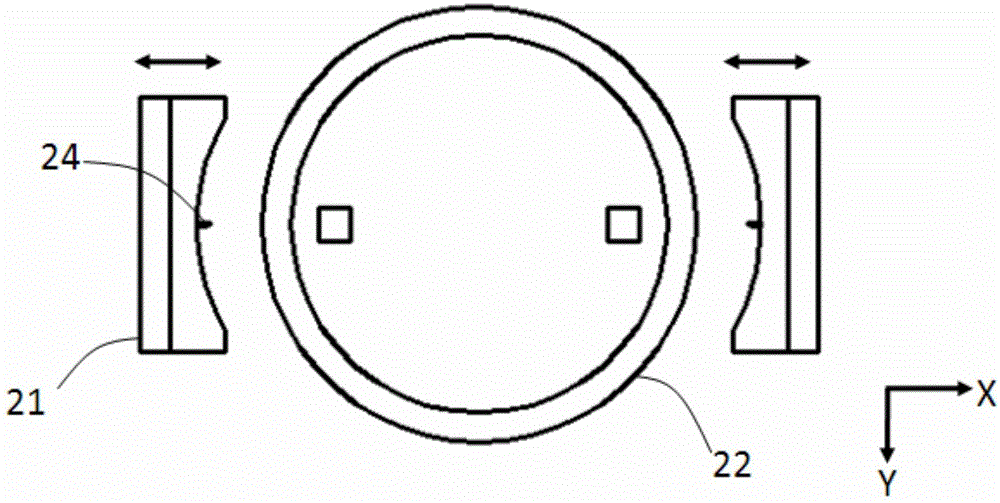

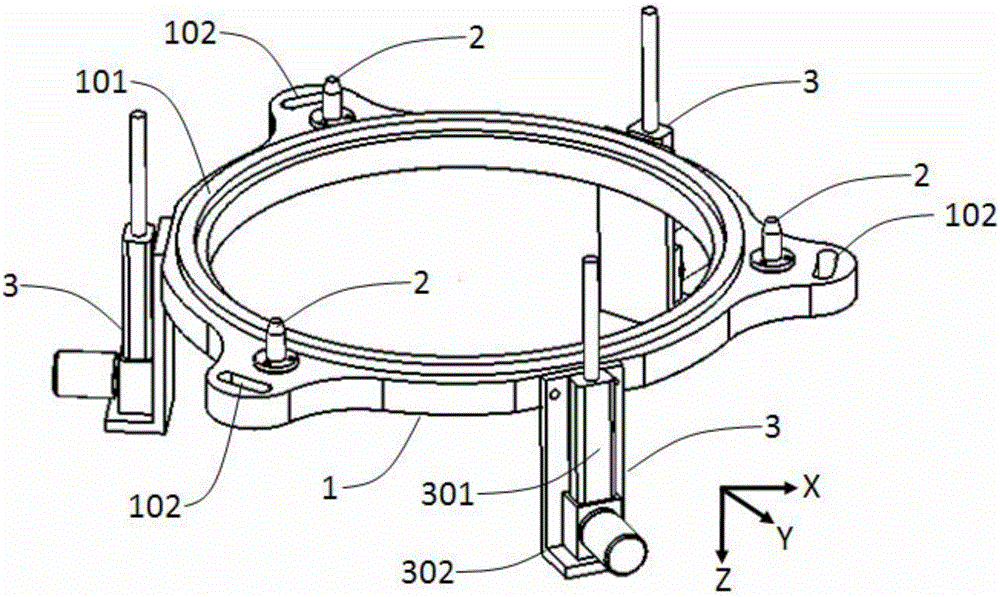

Positioning device for workpiece fixture in ion beam polishing equipment

The invention discloses a positioning device for a workpiece fixture in ion beam polishing equipment. The scheme includes that an annular positioning plate and the chuck type workpiece fixture interact with each other, and the annular positioning plate used as a positioning reference is horizontally and fixedly mounted, so that the workpiece fixture can be positioned by the positioning device. The positioning device is characterized in that a convex horizontal positioning plane, lifting devices and positioning pins are arranged on the upper surface of the annular positioning plate, the lifting devices and the positioning pins are symmetrically arranged along the peripheral edge of the positioning plate, a positioning plane which can cling to the horizontal positioning plane on the positioning plate is arranged on the fixture, and positioning holes which can be in one-to-one correspondence with the positioning pins on the positioning plate are formed in the fixture. The lifting devices lift the fixture with a clamped workpiece to a certain altitude and then slowly descend, so that the two positioning planes can completely cling to each other, all the positioning pins can be inserted into the positioning holes, and the workpiece fixture can be positioned. The positioning device has the advantages that positioning references are arranged on the same component, so that the workpiece fixture can be easily adjusted and can be completely positioned under the effect of the gravity of the fixture as long as the references are effectively adjusted, and the positioning device is simple in action; the positioning movement speed is controllable, so that positioning operation can be slowly carried out, and vibration can be greatly reduced and eliminated.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

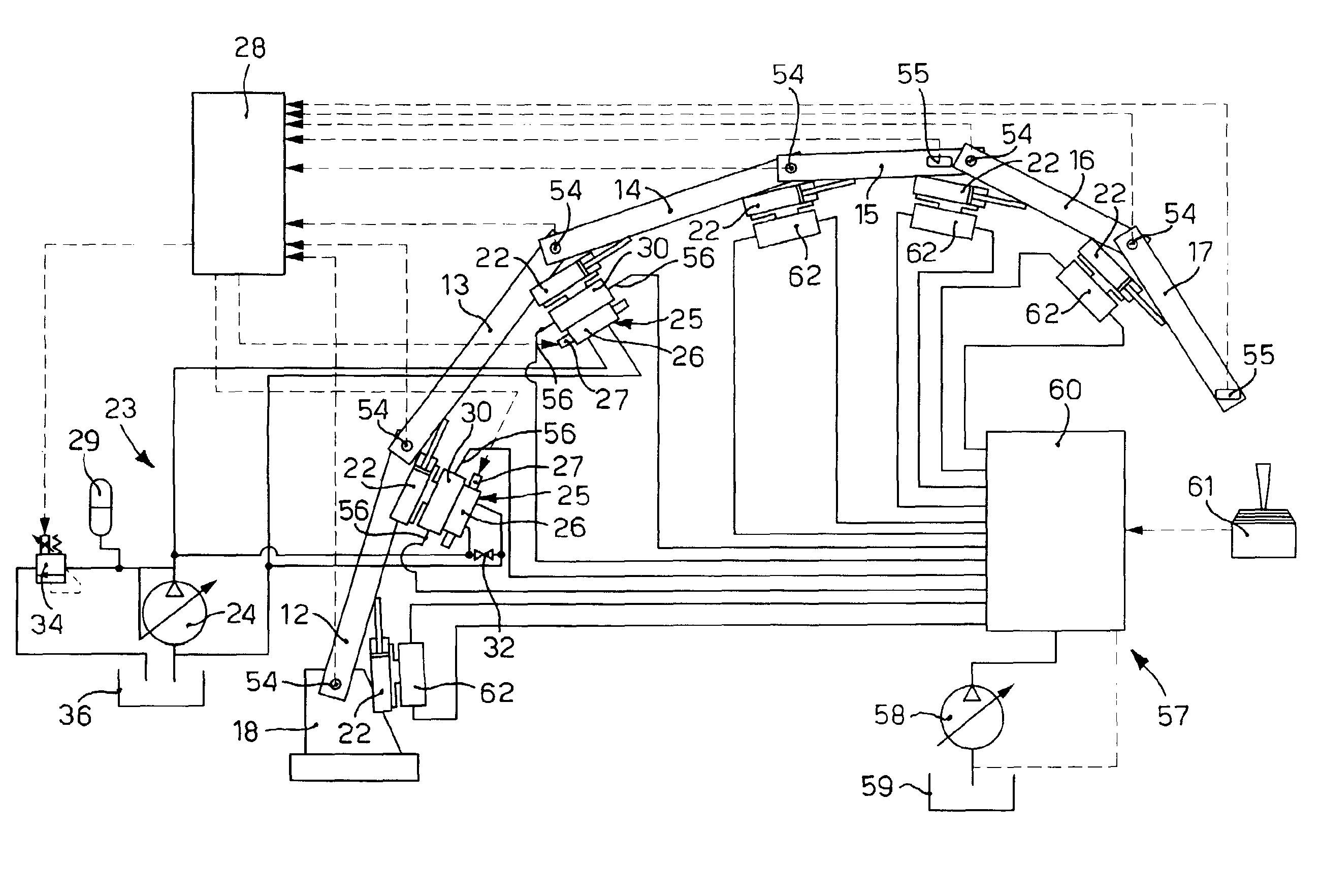

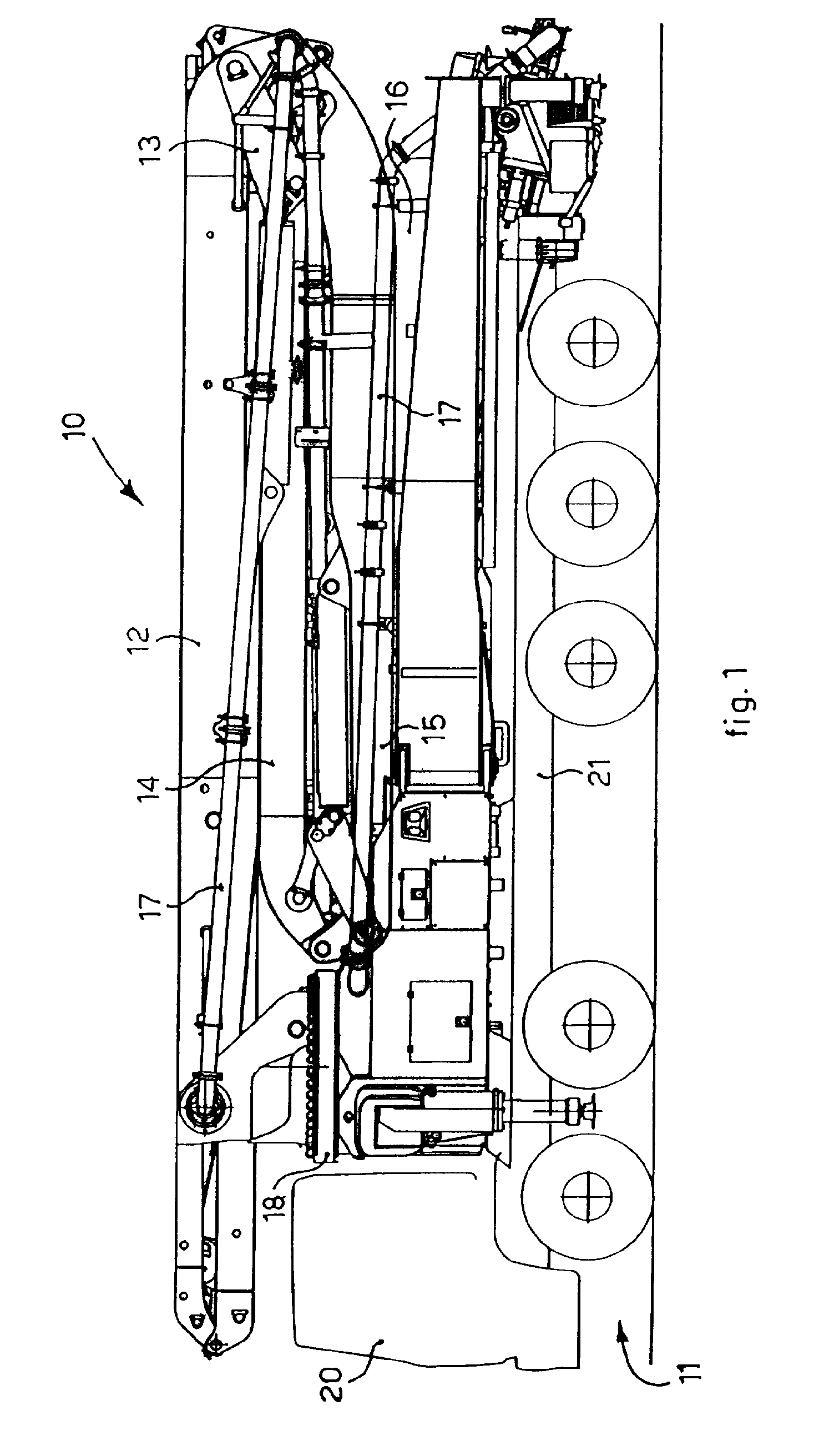

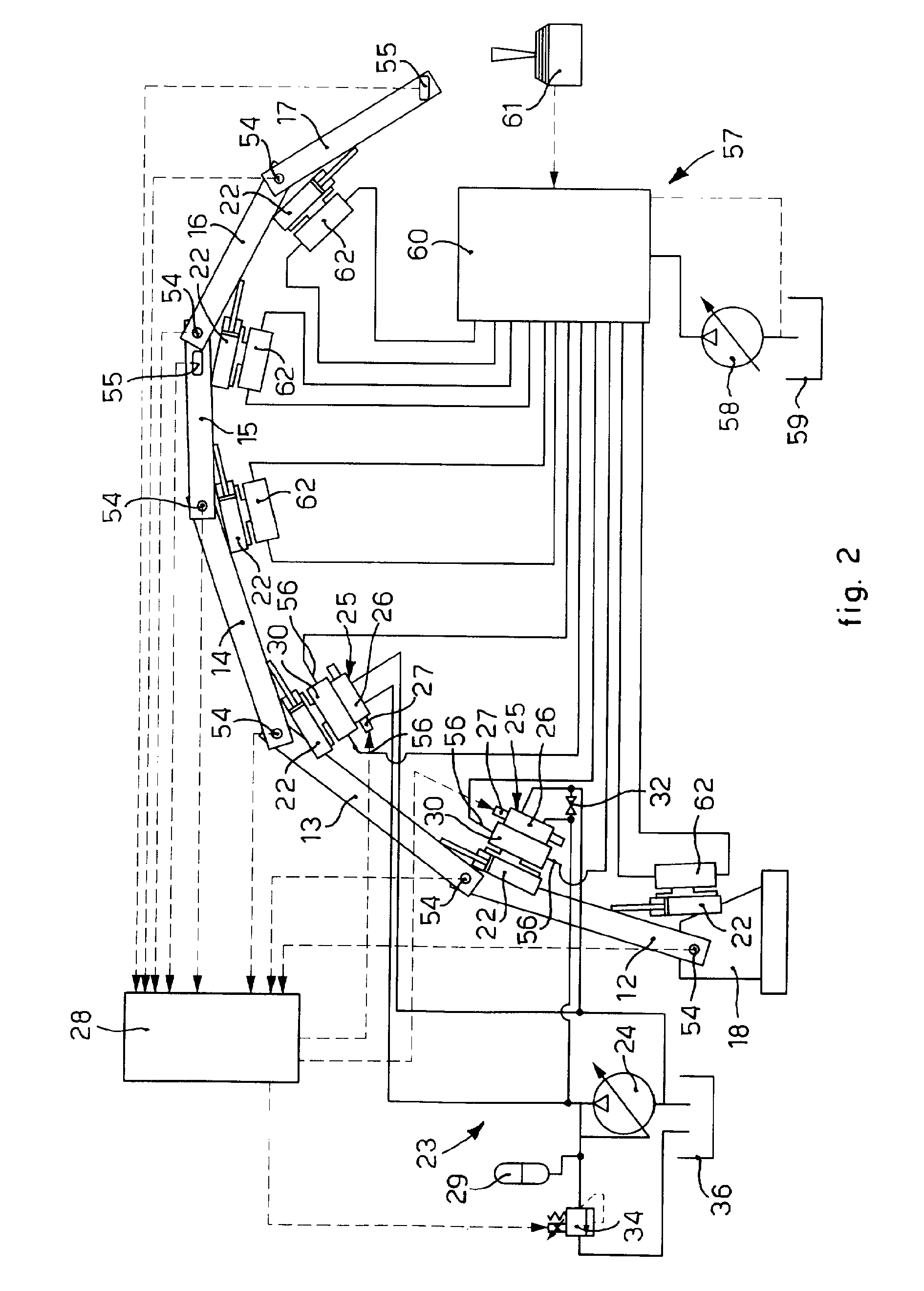

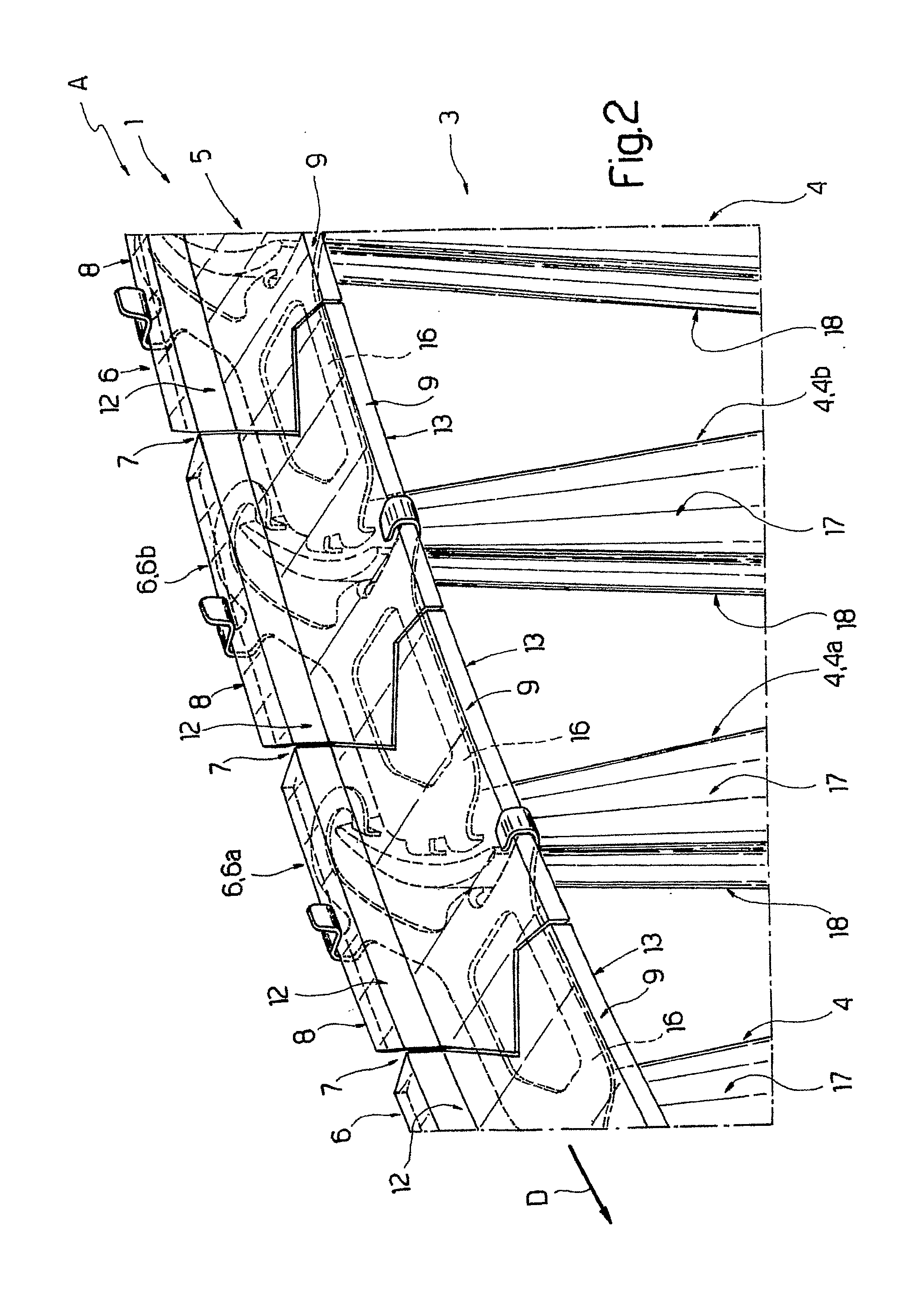

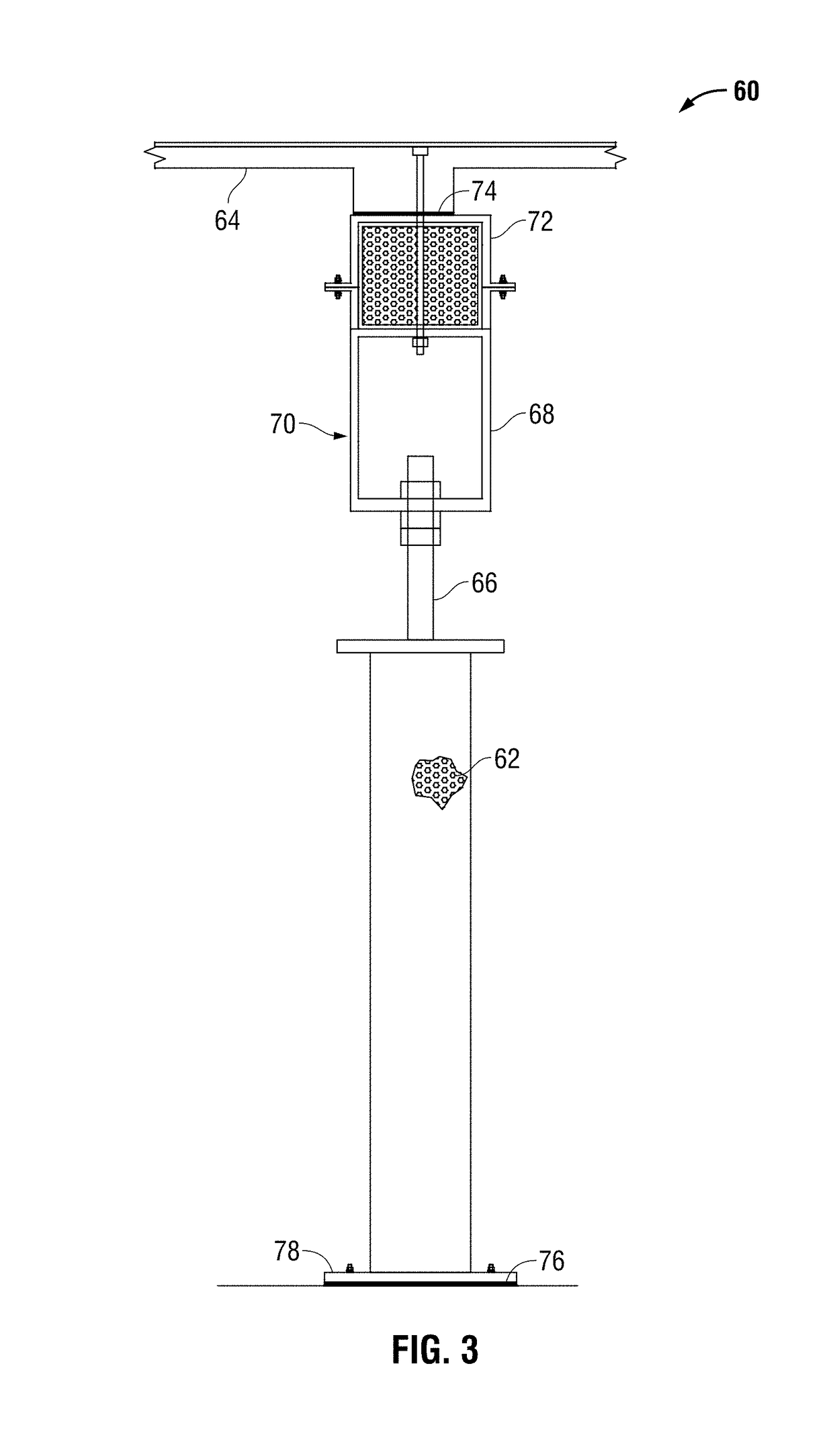

Device to actively control the vibrations of an articulated arm to pump concrete

ActiveUS8925310B2Reduce and eliminate vibrationReduce and even eliminate and vibrationFluid couplingsSoil-shifting machines/dredgersActuatorDriving circuit

The device to actively control the vibrations of an articulated arm consisting of a plurality of segments each comprising at least its own actuator associated with a hydraulic drive circuit including a block valve. At least one of said actuators is associated with an hydraulic control circuit of the vibrations, comprising at least a sensor able to detect the vibrations and / or the position of one or more segments, a processing unit to process the signals of the sensor / sensors and a pump commanded by the electronic command board and cooperating with said block valve. The hydraulic control circuit is associated with the hydraulic drive circuit.

Owner:CIFA

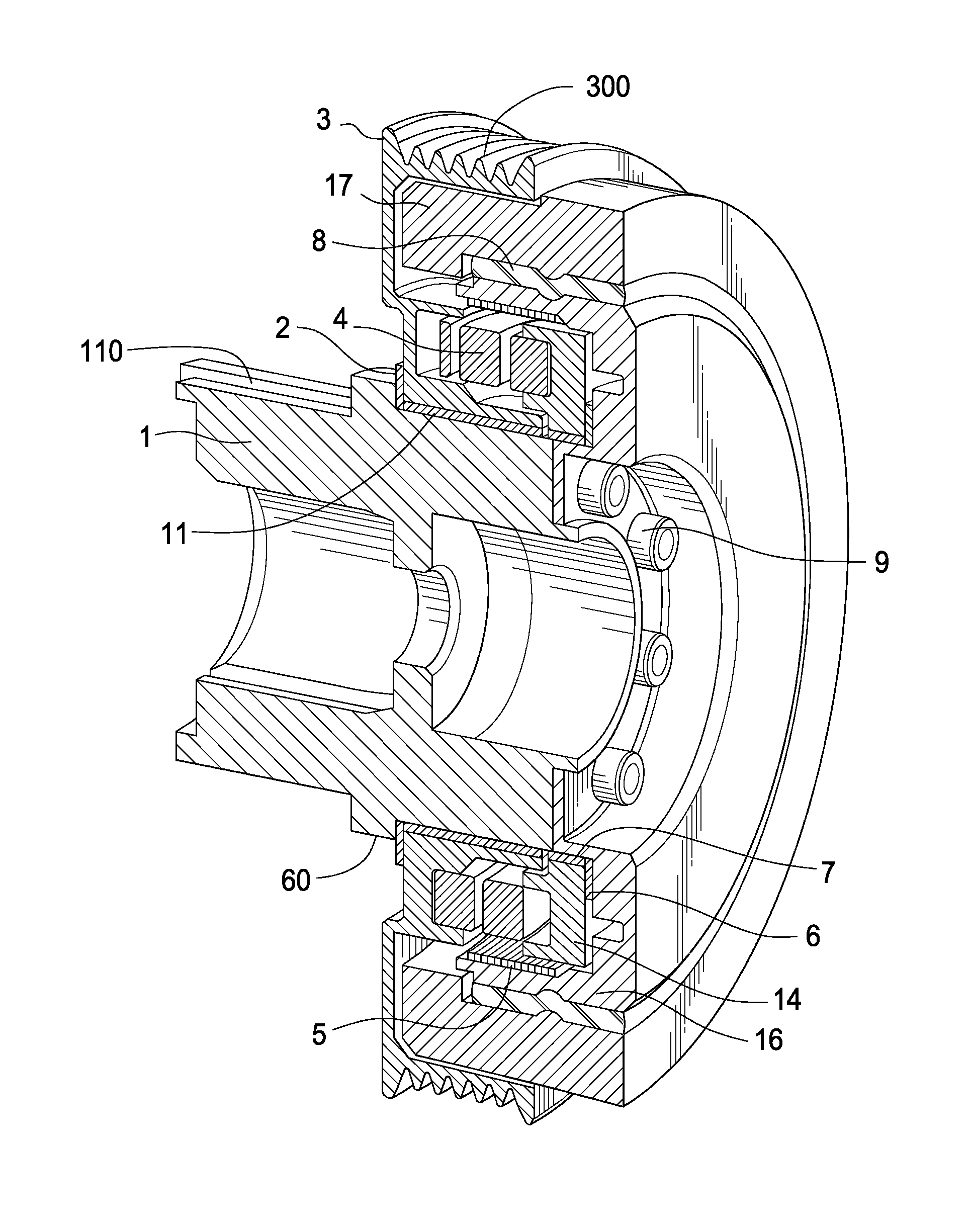

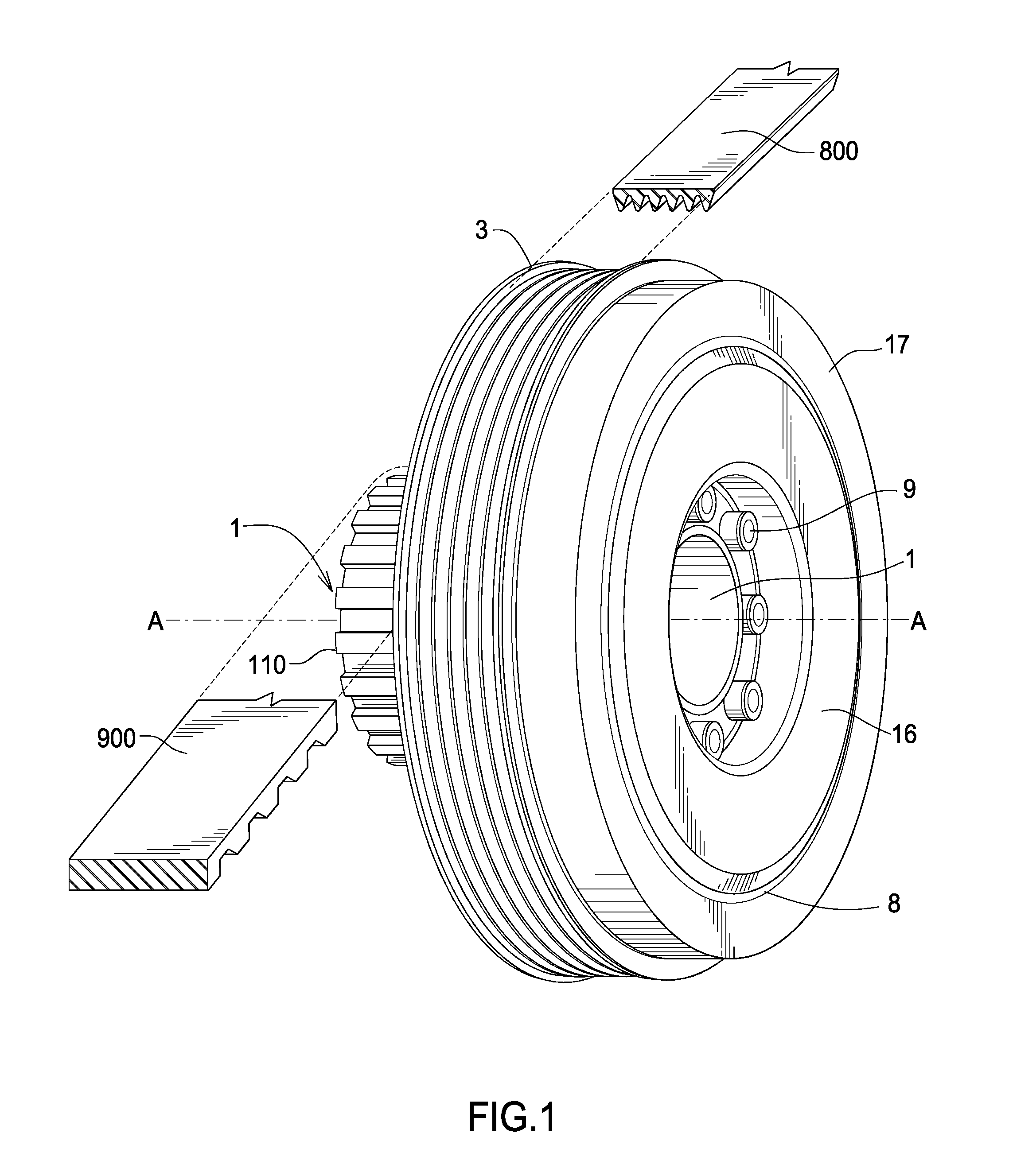

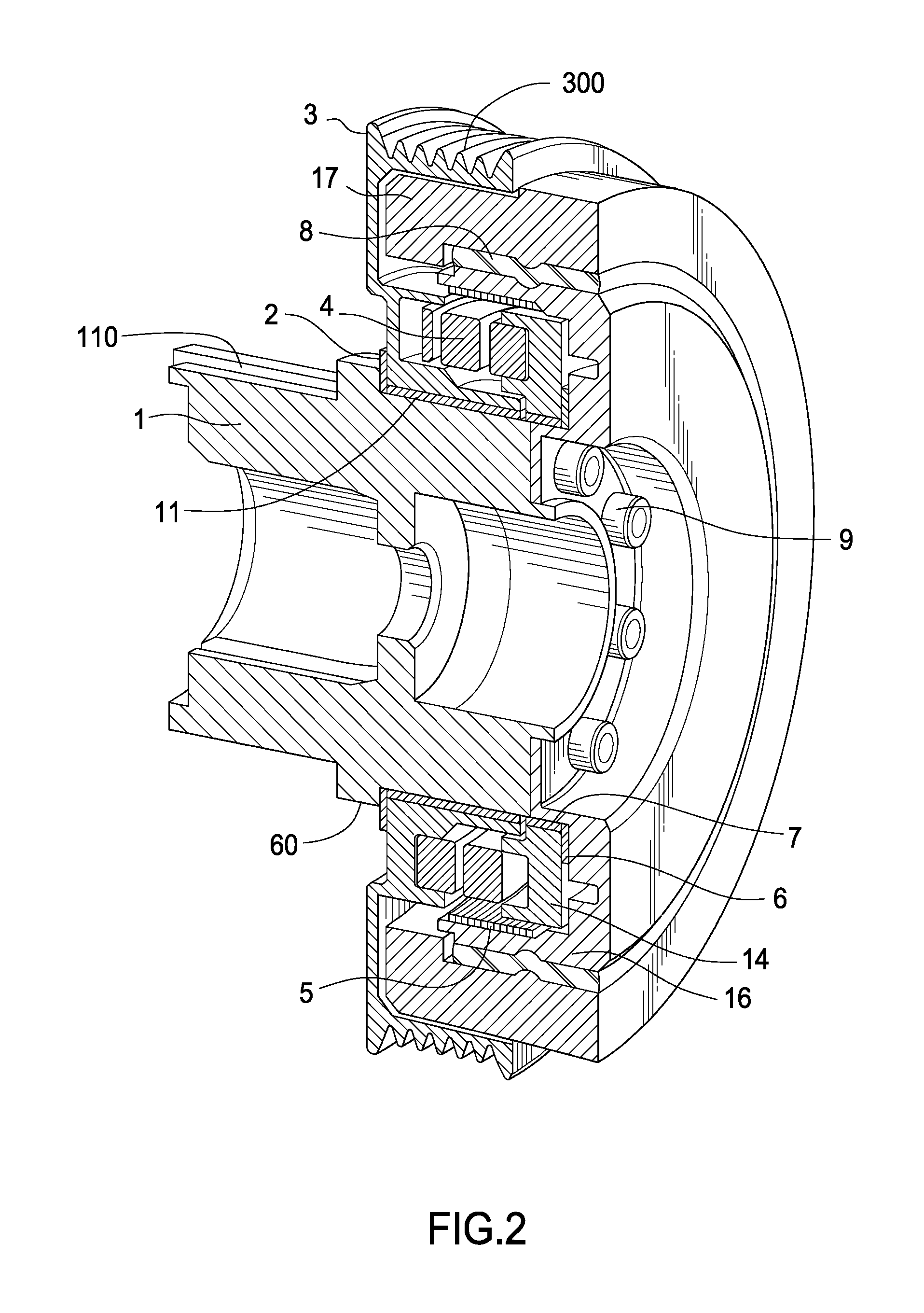

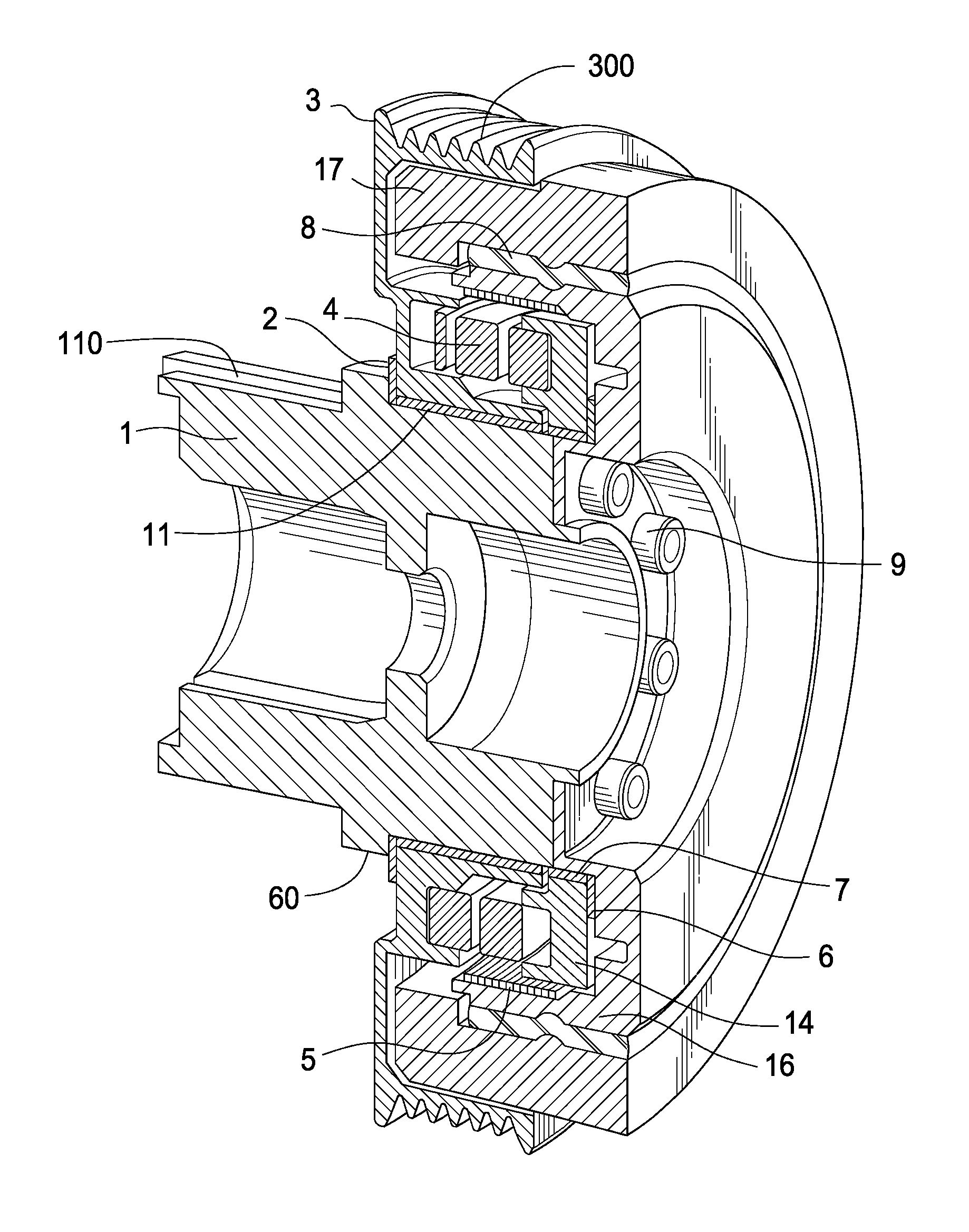

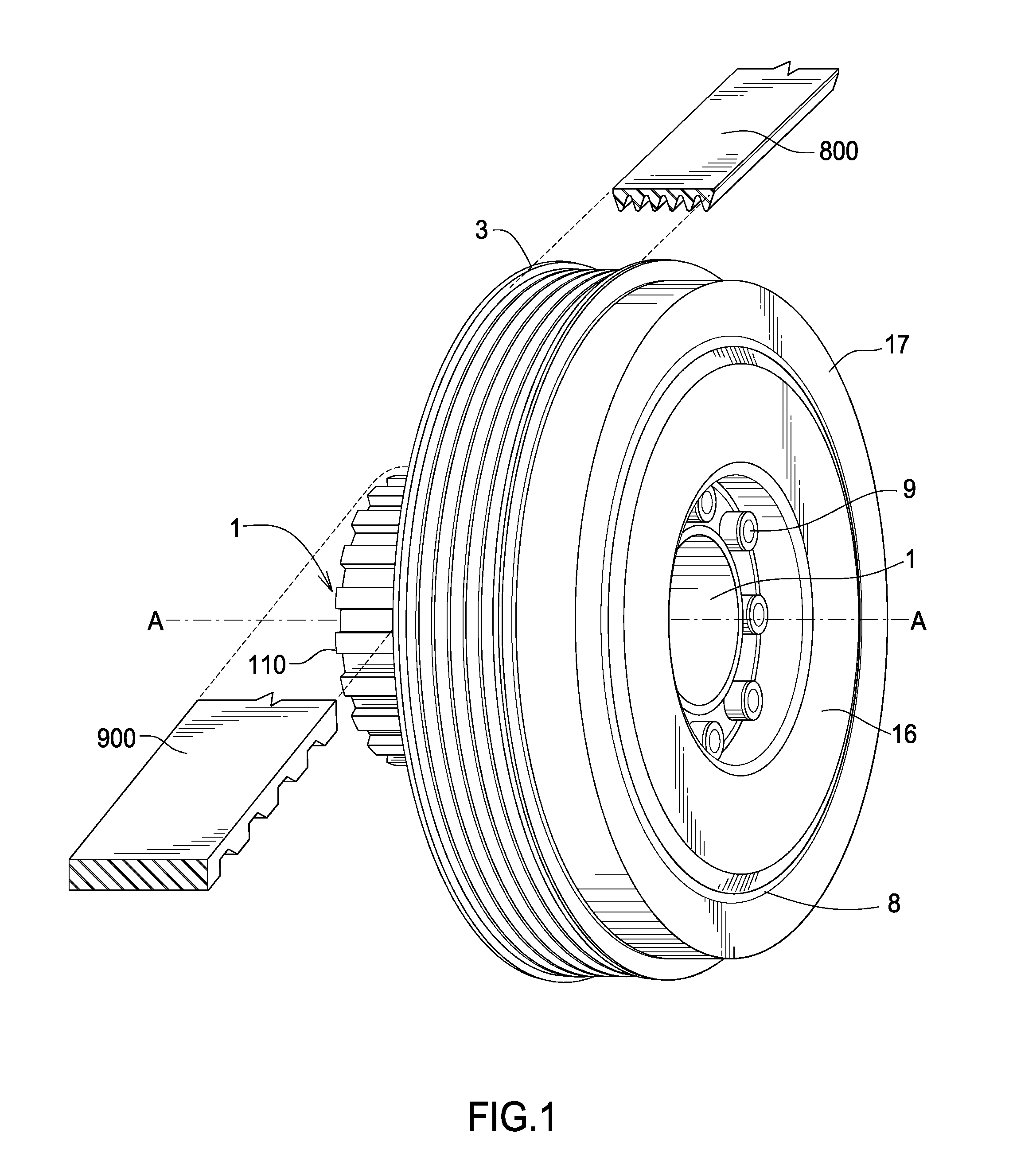

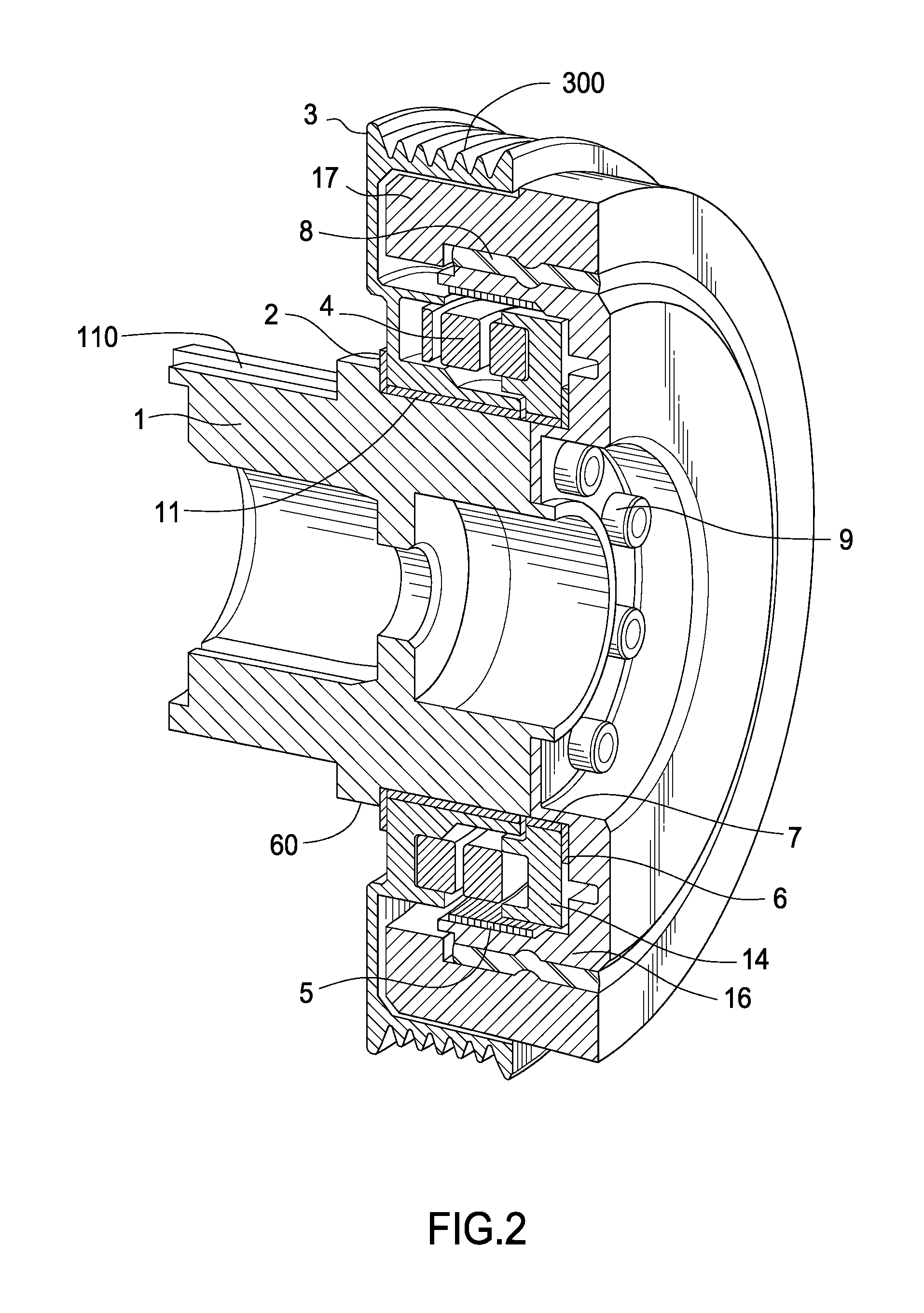

Crankshaft isolating pulley

ActiveUS20160069418A1Reduce noiseReduce vibrationRotating vibration suppressionShock absorbersEngineeringCrankshaft

An isolating pulley comprising a hub comprising an inertia carrier, the inertia carrier having an inner surface, a spring carrier journalled to the hub, the spring carrier having a releasable driving engagement with the inertia carrier, a pulley journalled to the hub, a spring drivingly engaged between the spring carrier and the pulley, a clutch spring having a frictional engagement with the inner surface, and which frictional engagement is partially releasable upon a temporary, pressing contact of the pulley upon the clutch spring.

Owner:THE GATES CORP

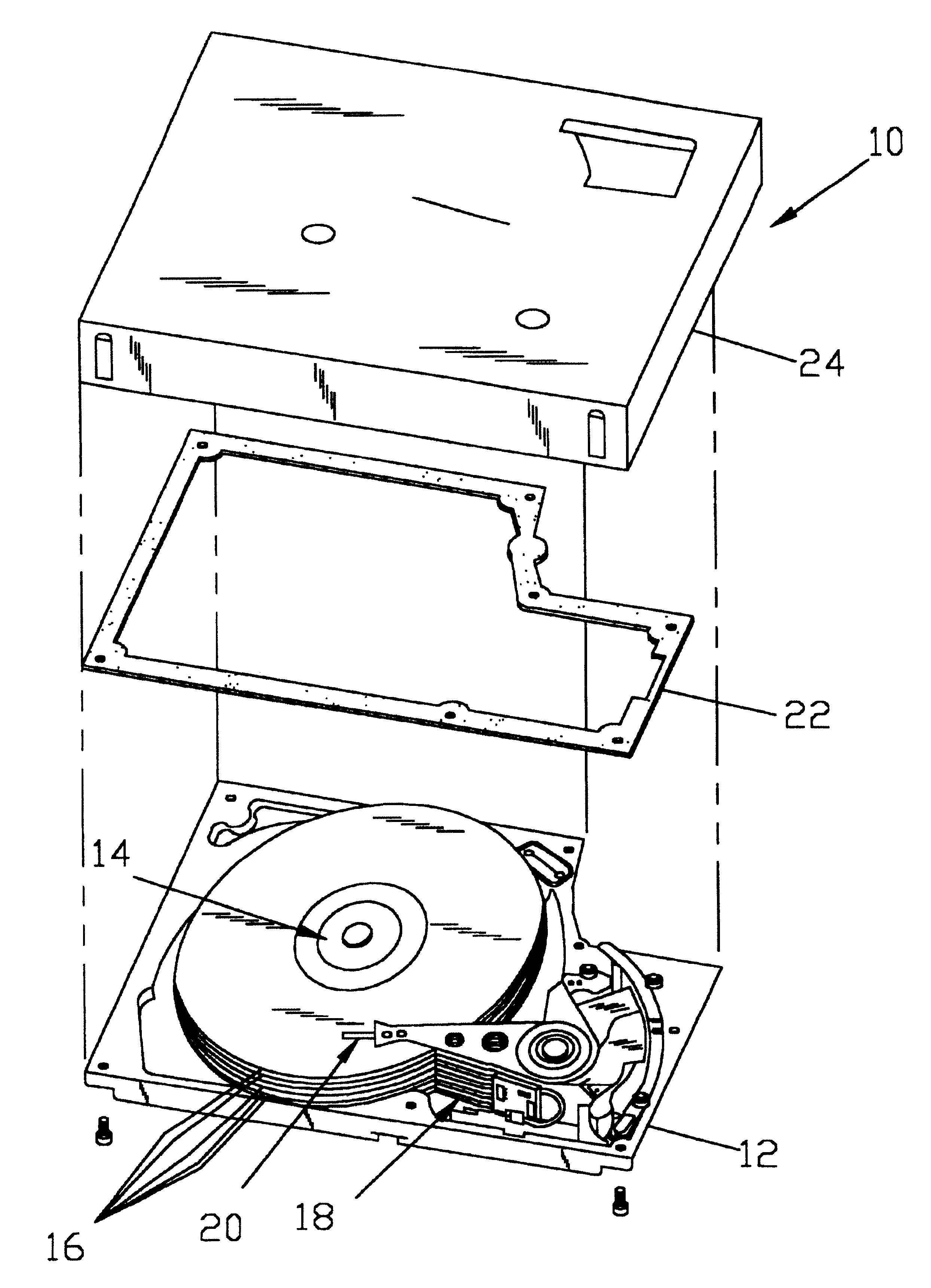

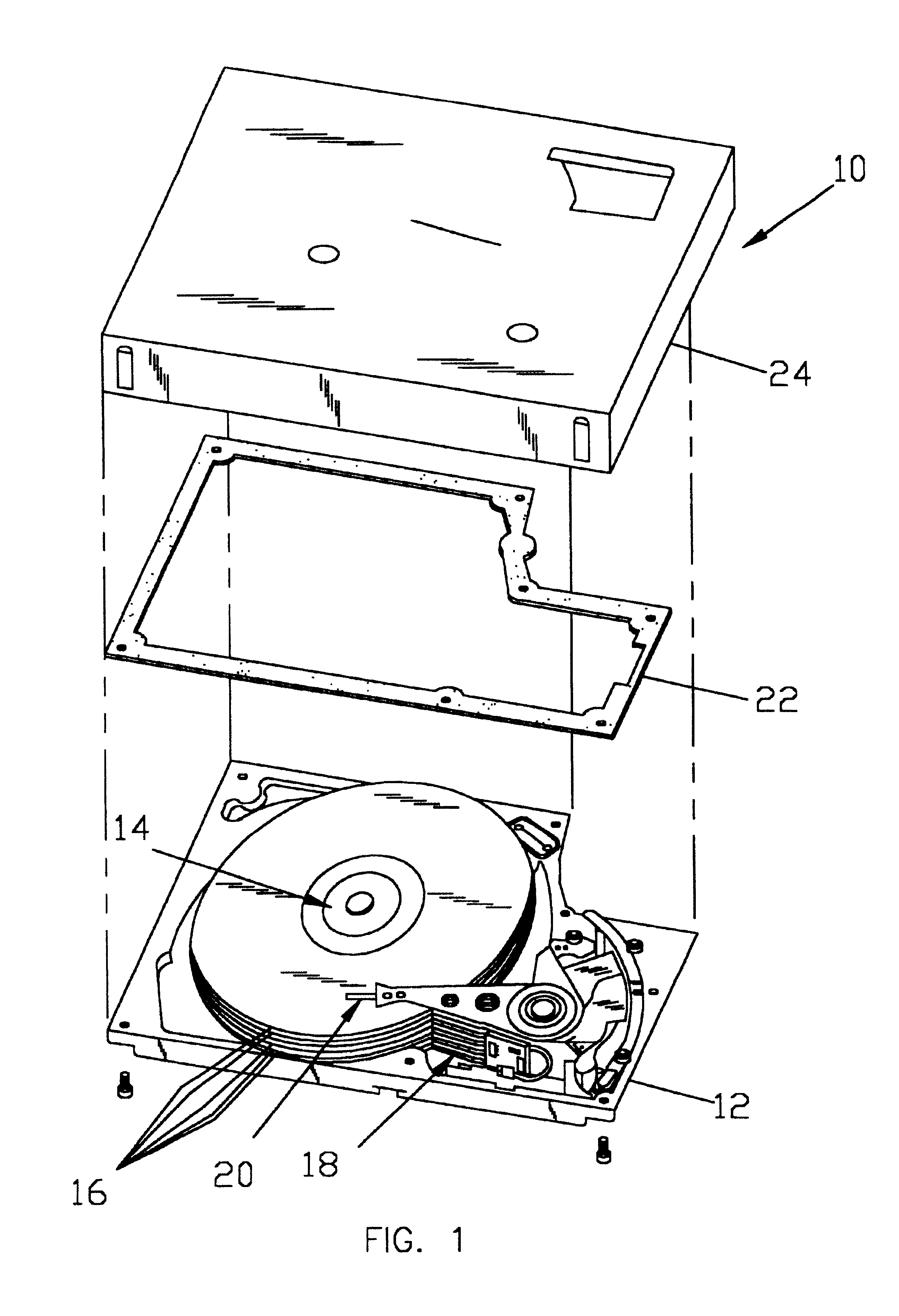

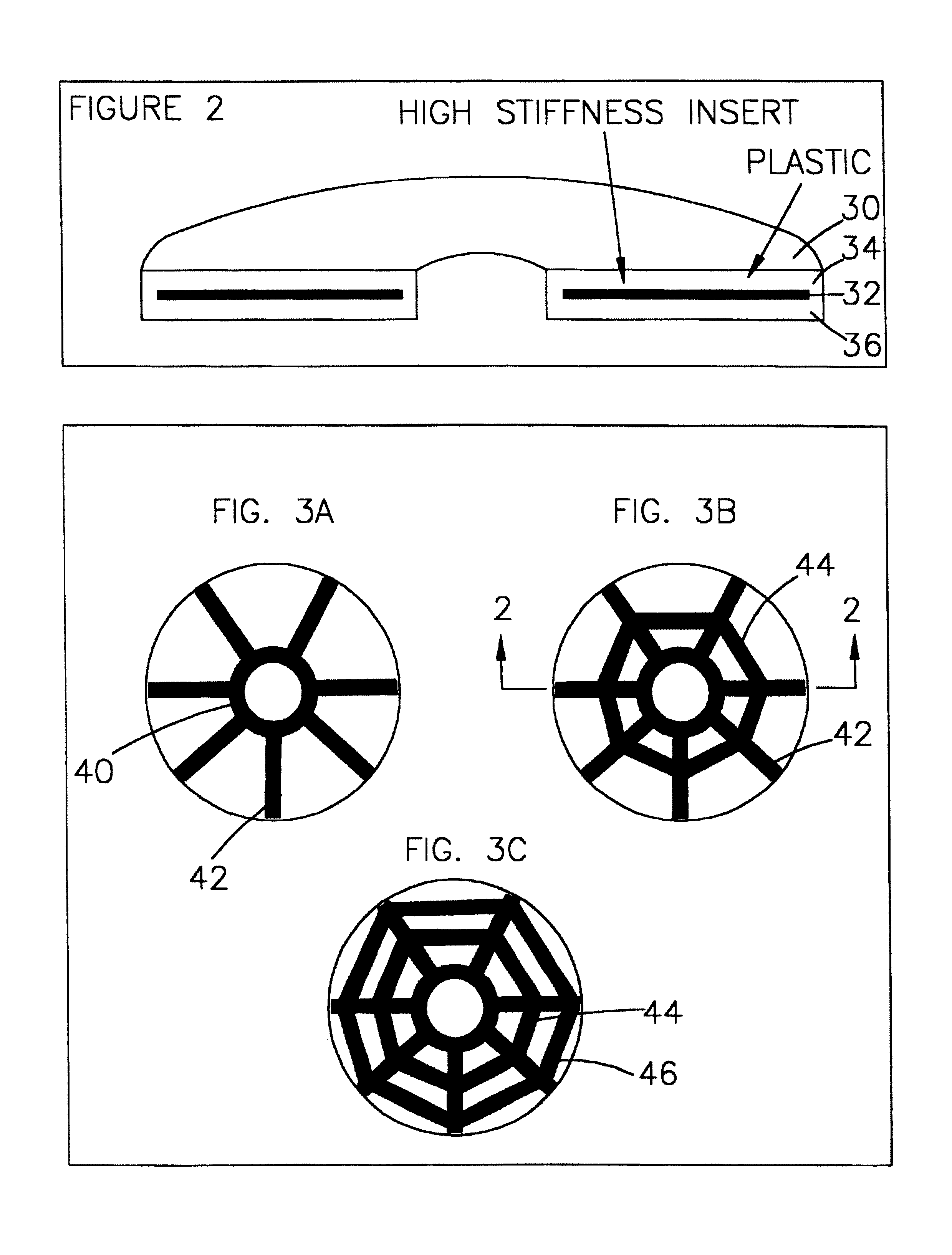

Design of a rigid disc plastic substrate with high stiffness insert

InactiveUS6850391B1Easily and economically manufacturedIncrease speedDisposition/mounting of recording headsBase layers for recording layersHigh stiffnessEngineering

An injection molded plastic disc substrate incorporating a stiff insert made of a very stiff material (metal, ceramic, composite . . . e.g. silicon) embedded in the plastic matrix. Preferably, the insert has a circular center region and radially extending fingers. Additional features of the web may include one or more chordal connecting elements extending between the fingers. In this way, both vibration or flutter in the circumferential or radial direction is suppressed by the insert.

Owner:SEAGATE TECH LLC

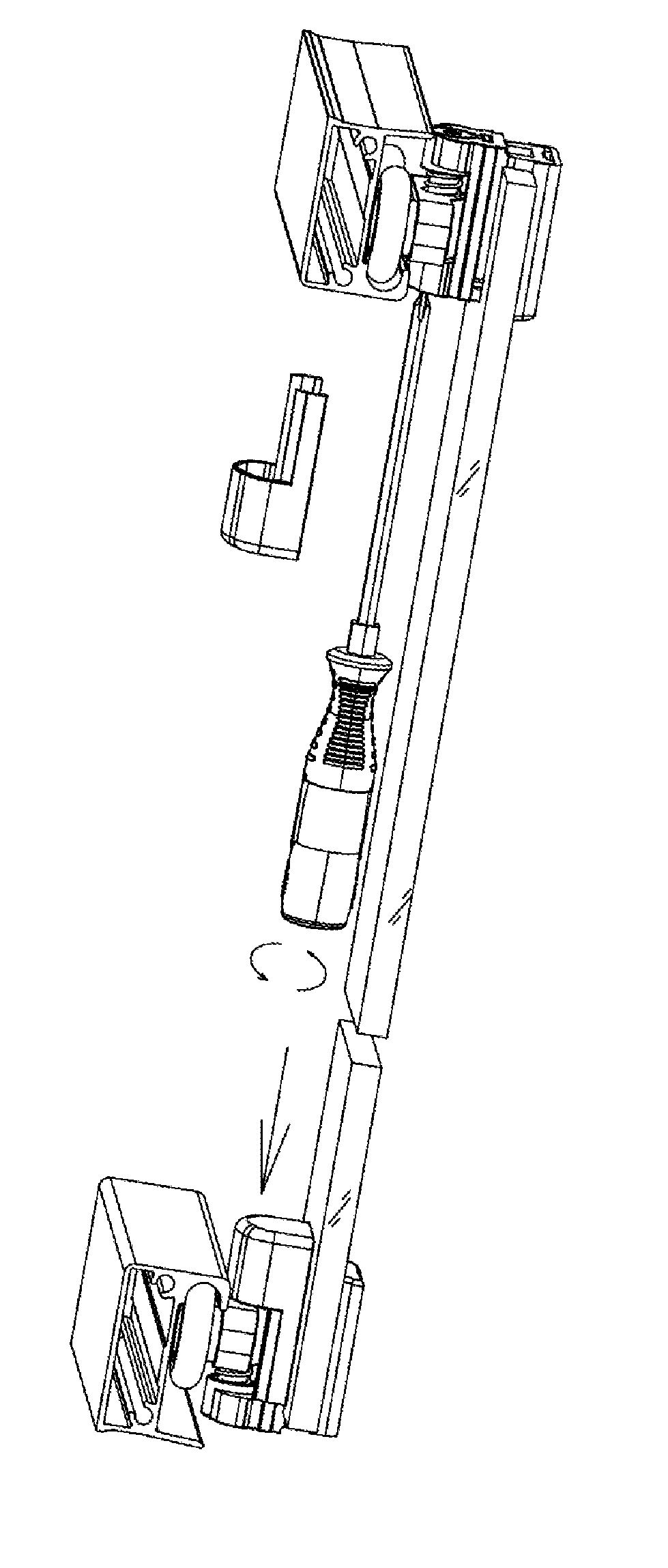

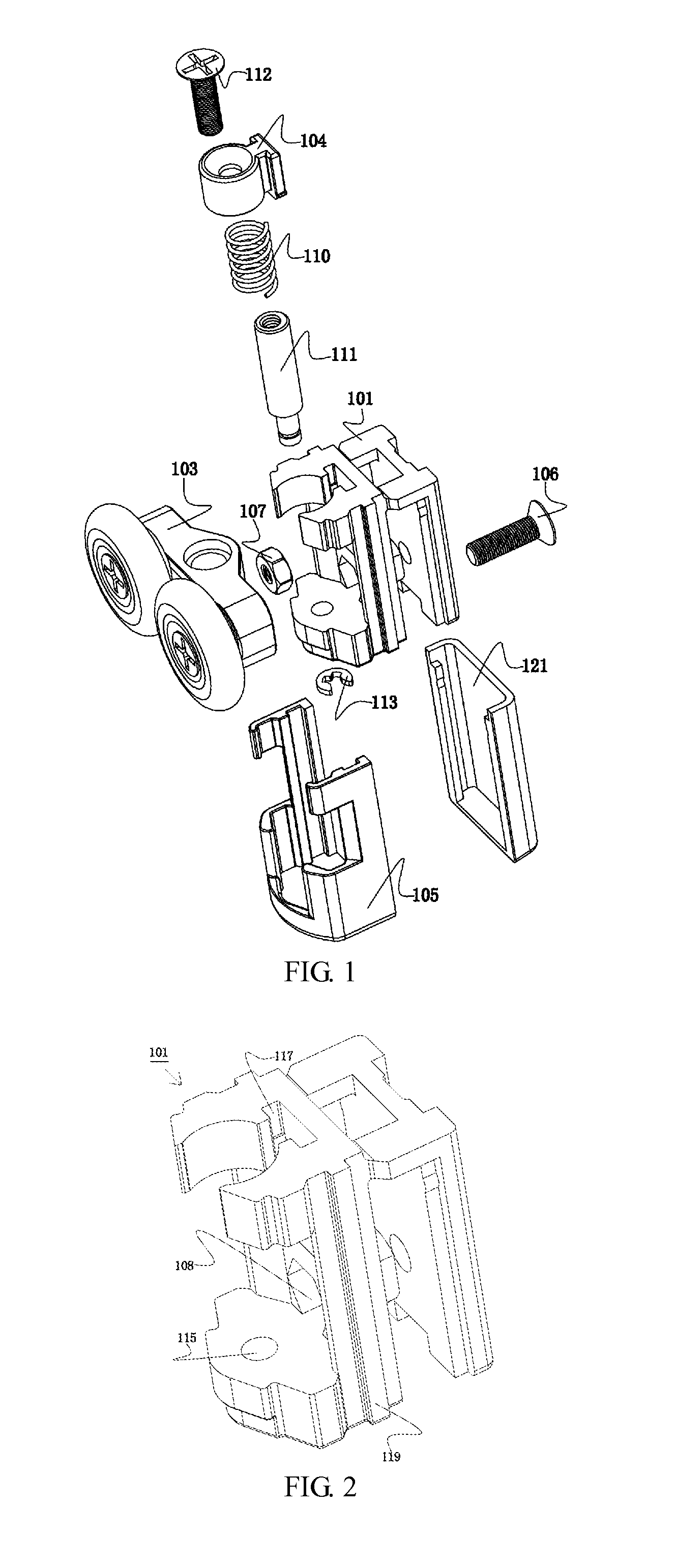

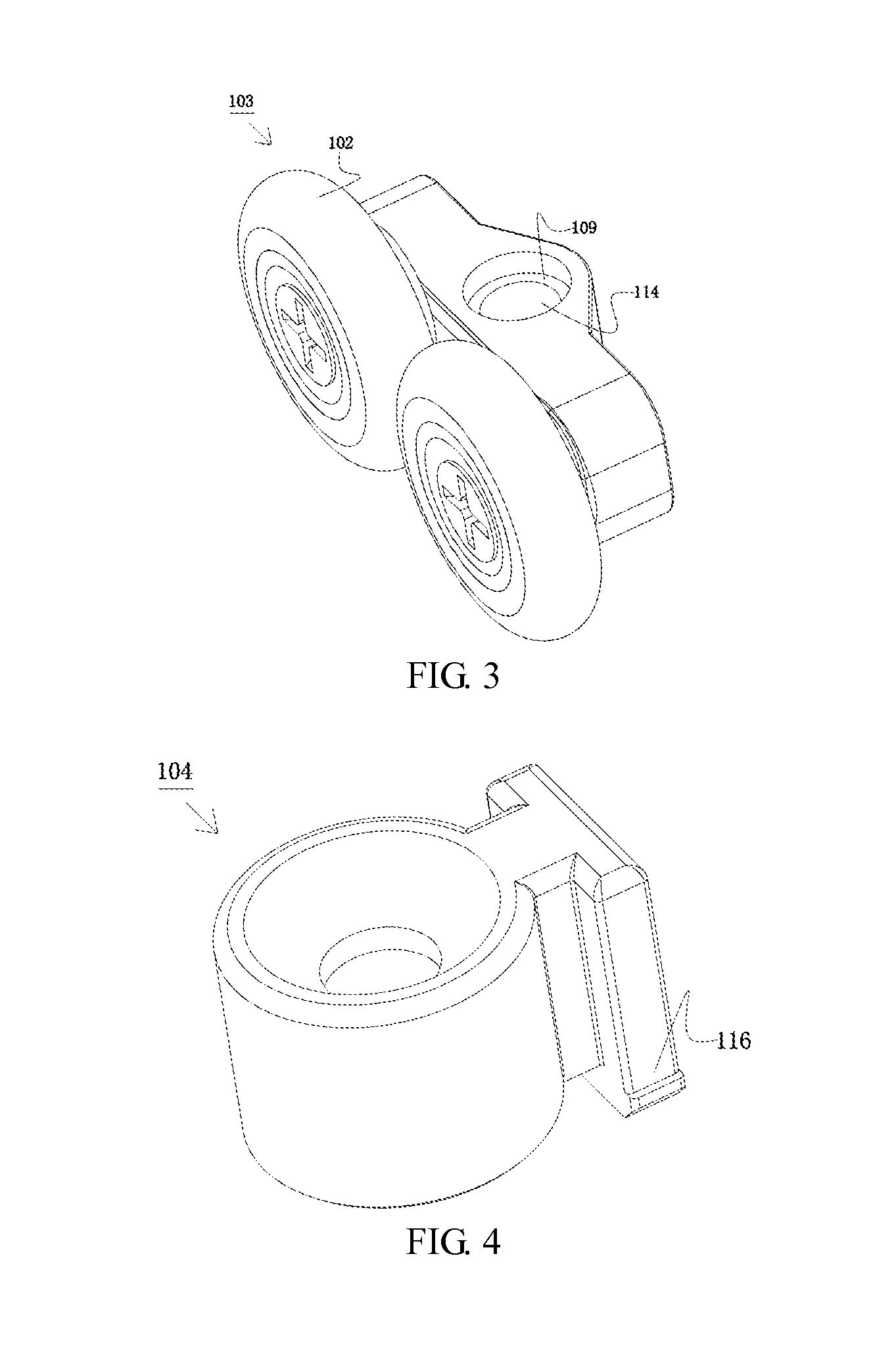

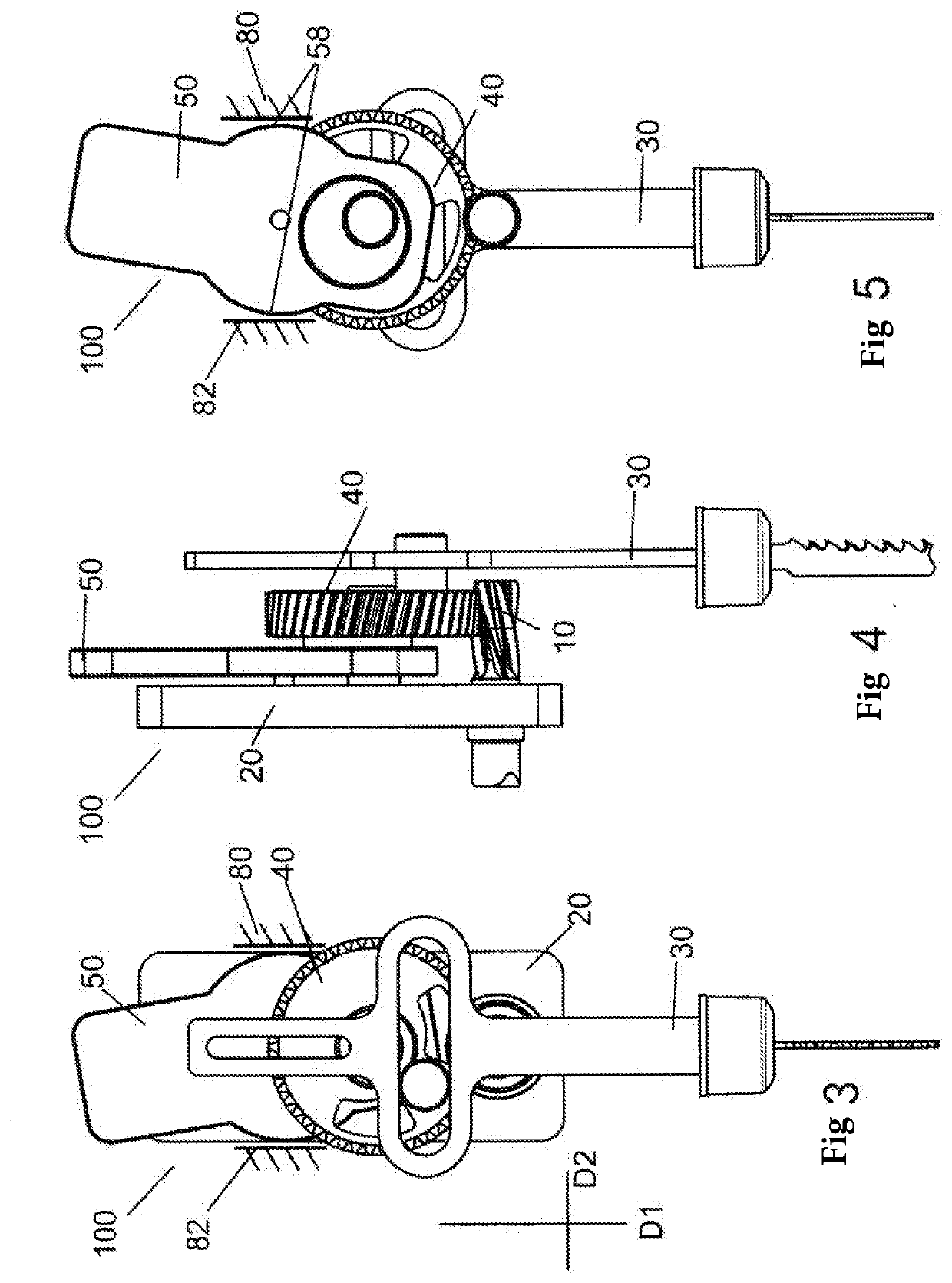

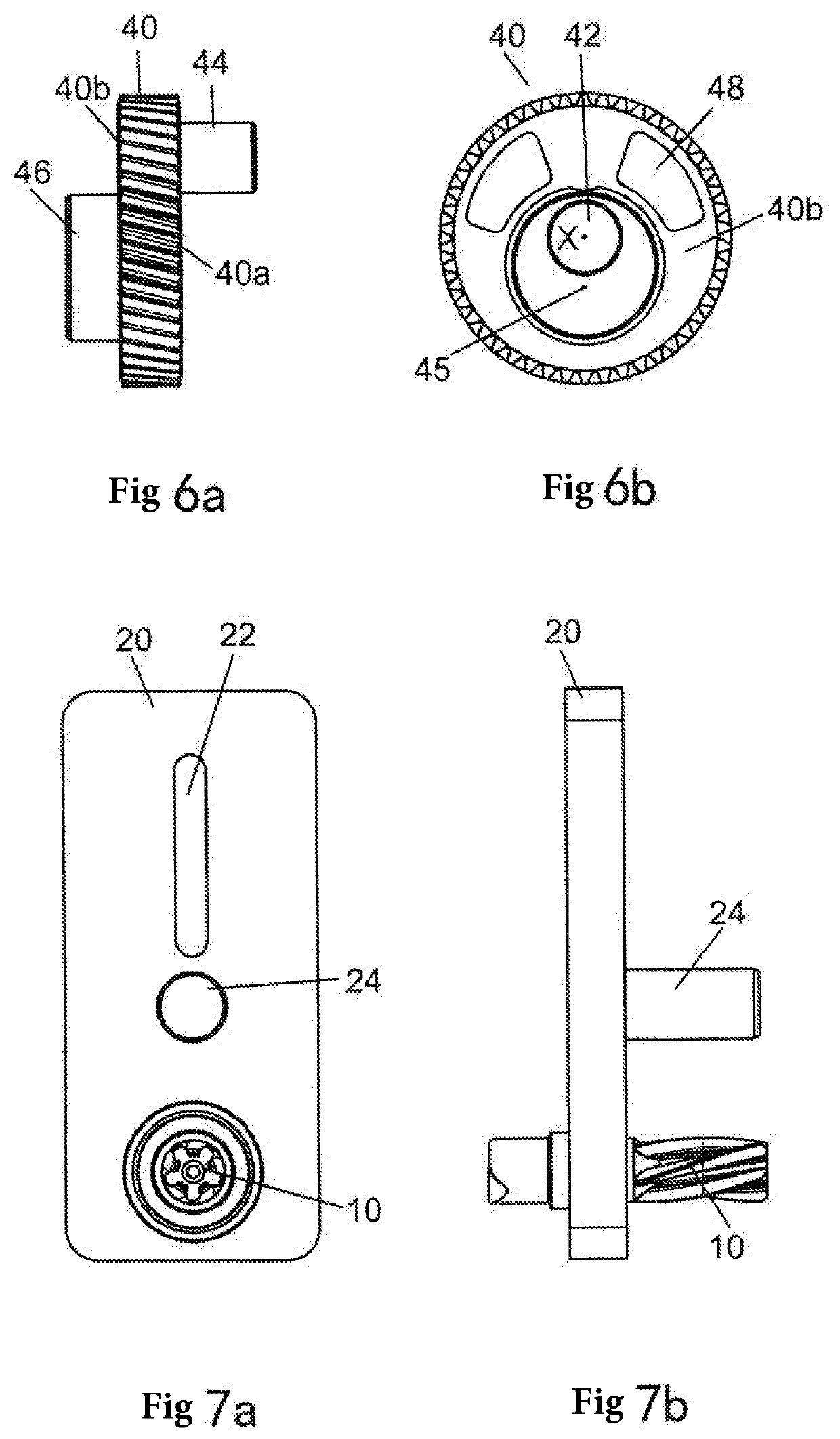

Shower door pulley device

InactiveUS20140115969A1Reduce and eliminate vibrationLess time-consumingMan-operated mechanismWing suspension devicesEngineeringPulley

A shower door pulley device is provided which comprises a pulley seat installed on a movable door; a pulley bracket having at least one pulley and an elastic member; a pressing block to press said elastic member and slidable relative to the pulley seat; a sliding cover slidablely mounted on said pulley seat, supporting the pulley bracket.

Owner:FOSHAN IDEAL

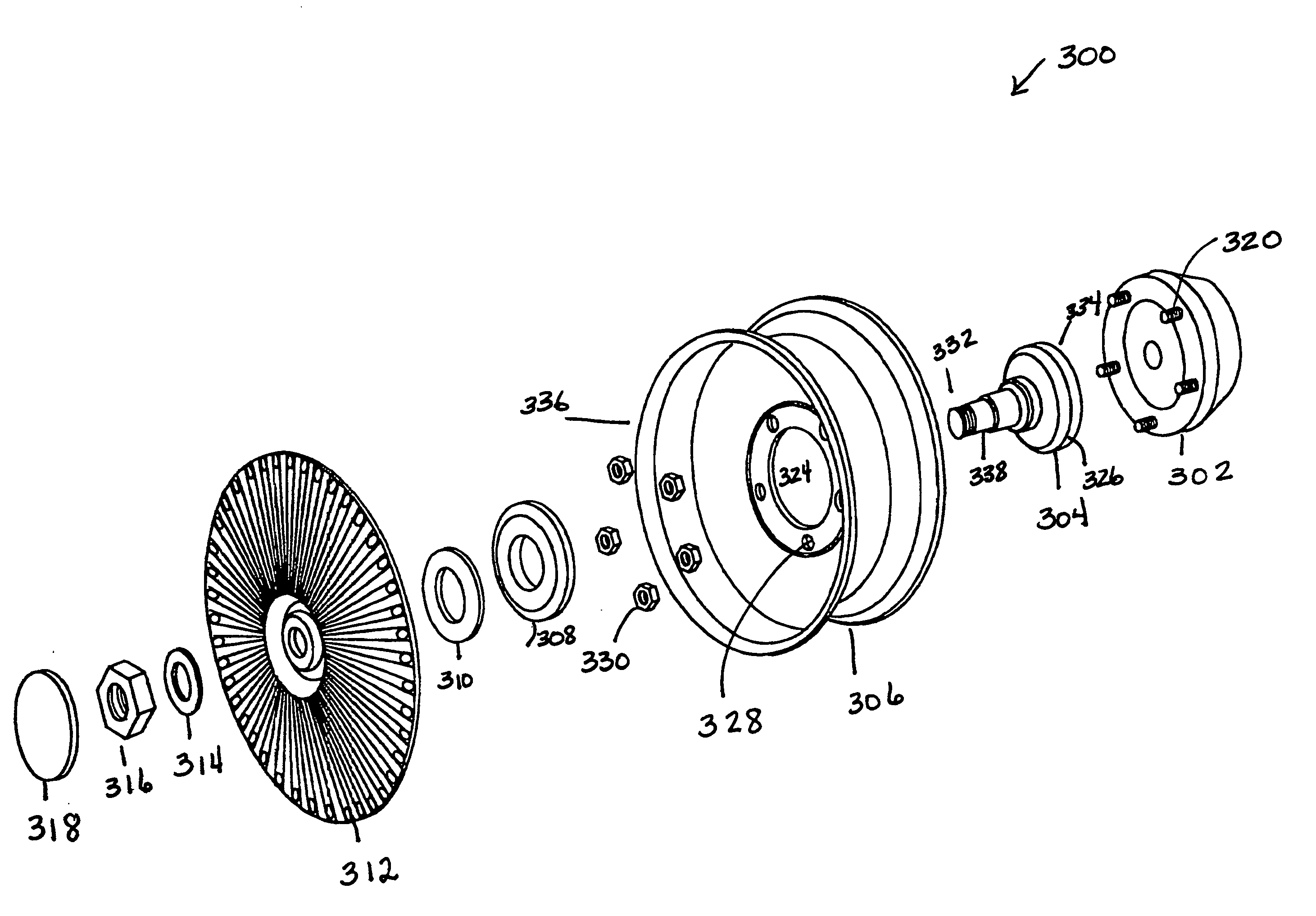

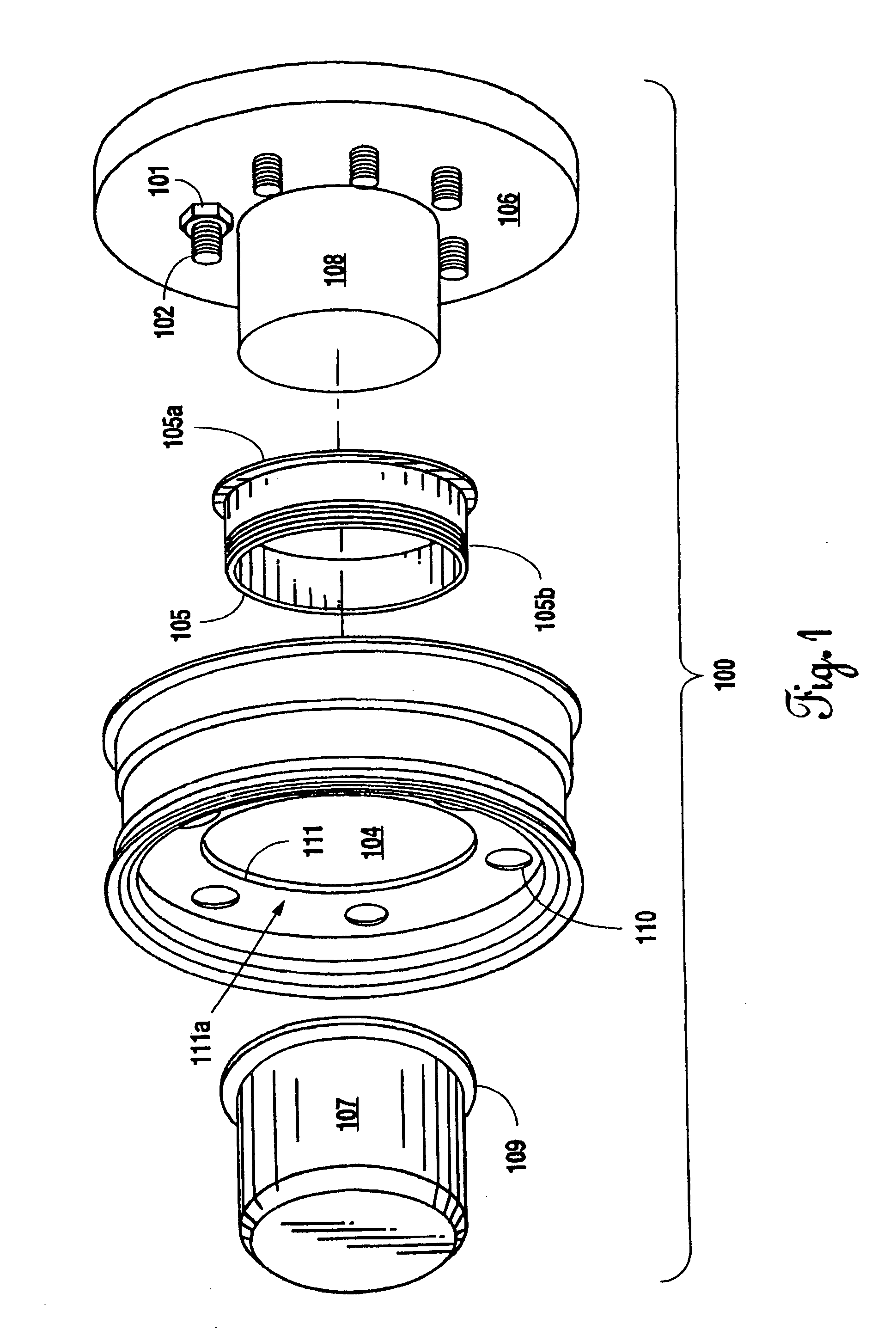

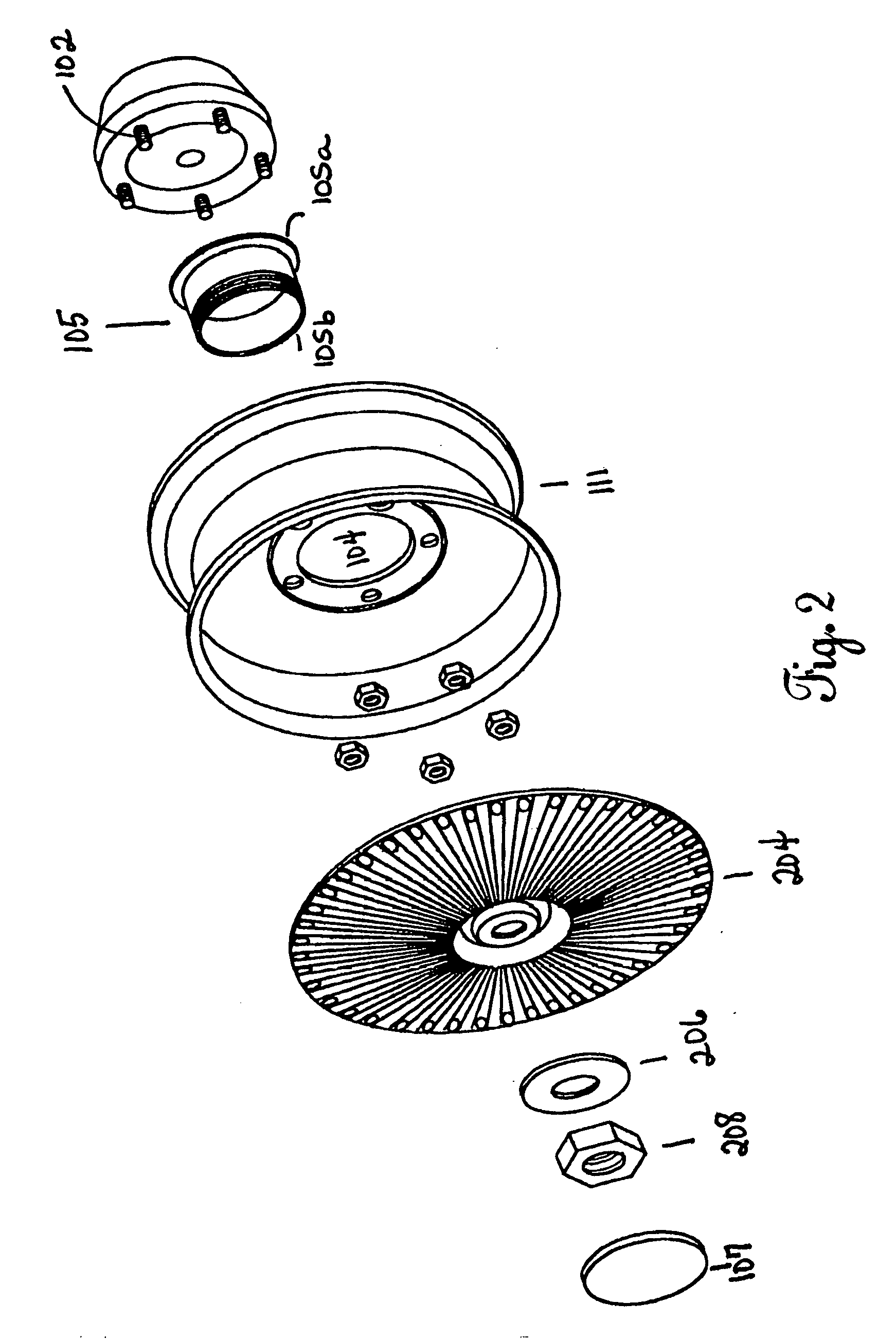

Custom wheel assembly

A custom wheel assembly for use in mounting spinners to hub centric wheels. This is accomplished through the use of a mandrel hub that is placed through the center bore of a hub centric wheel. This mandrel hub incorporates a shaft that permits the attachment of a spinner to the wheel.

Owner:NECAISE RONALD E

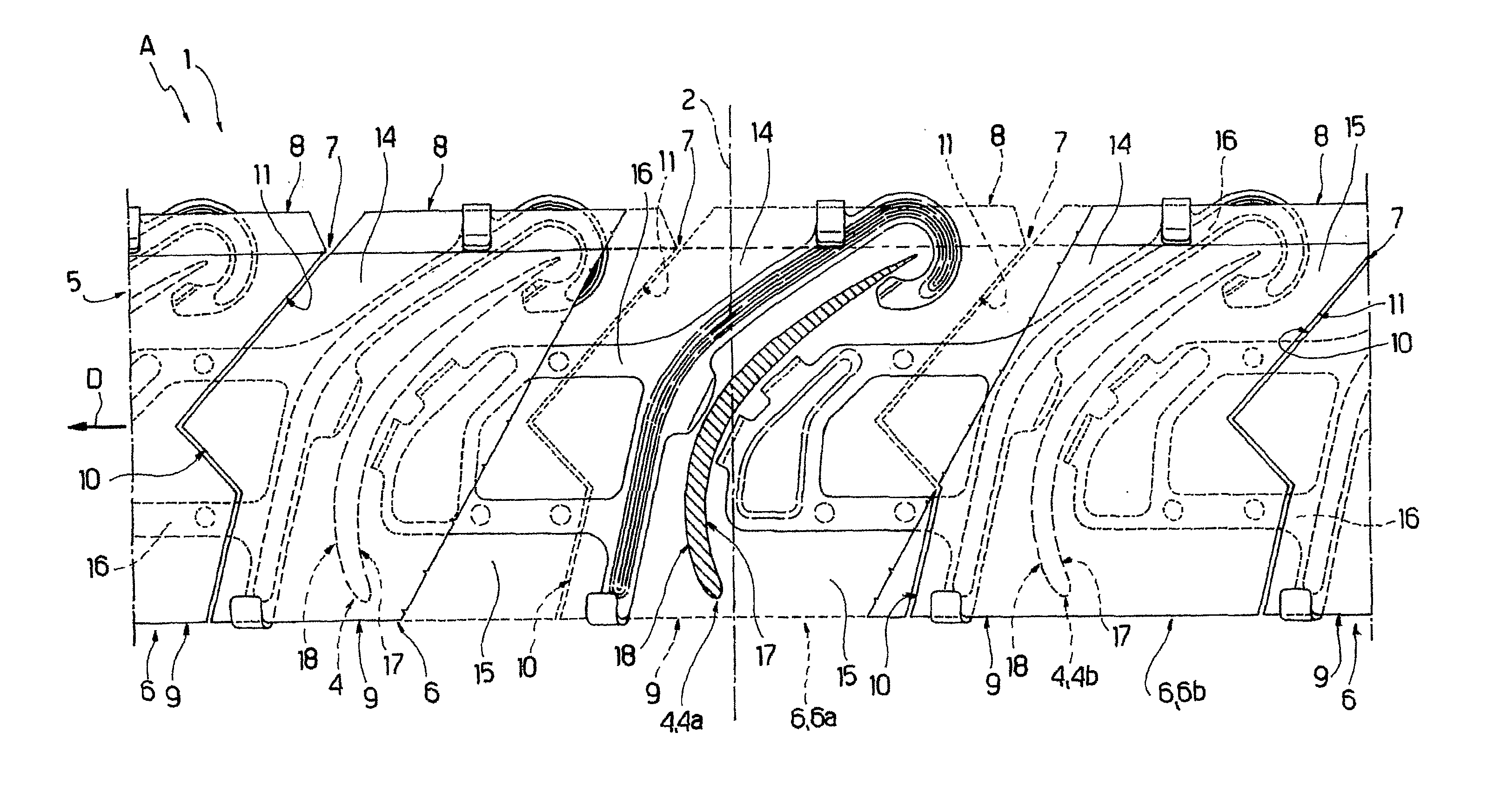

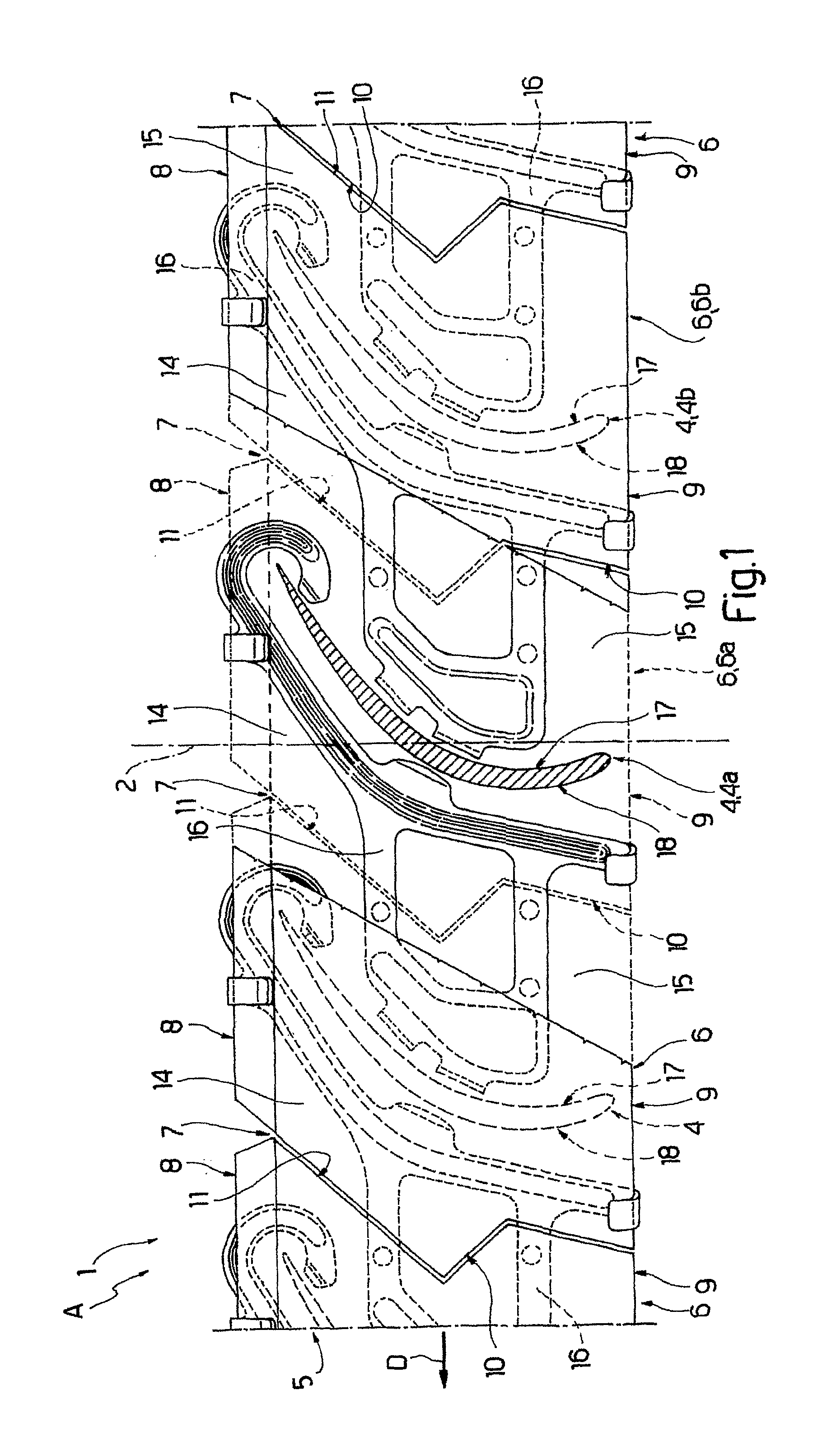

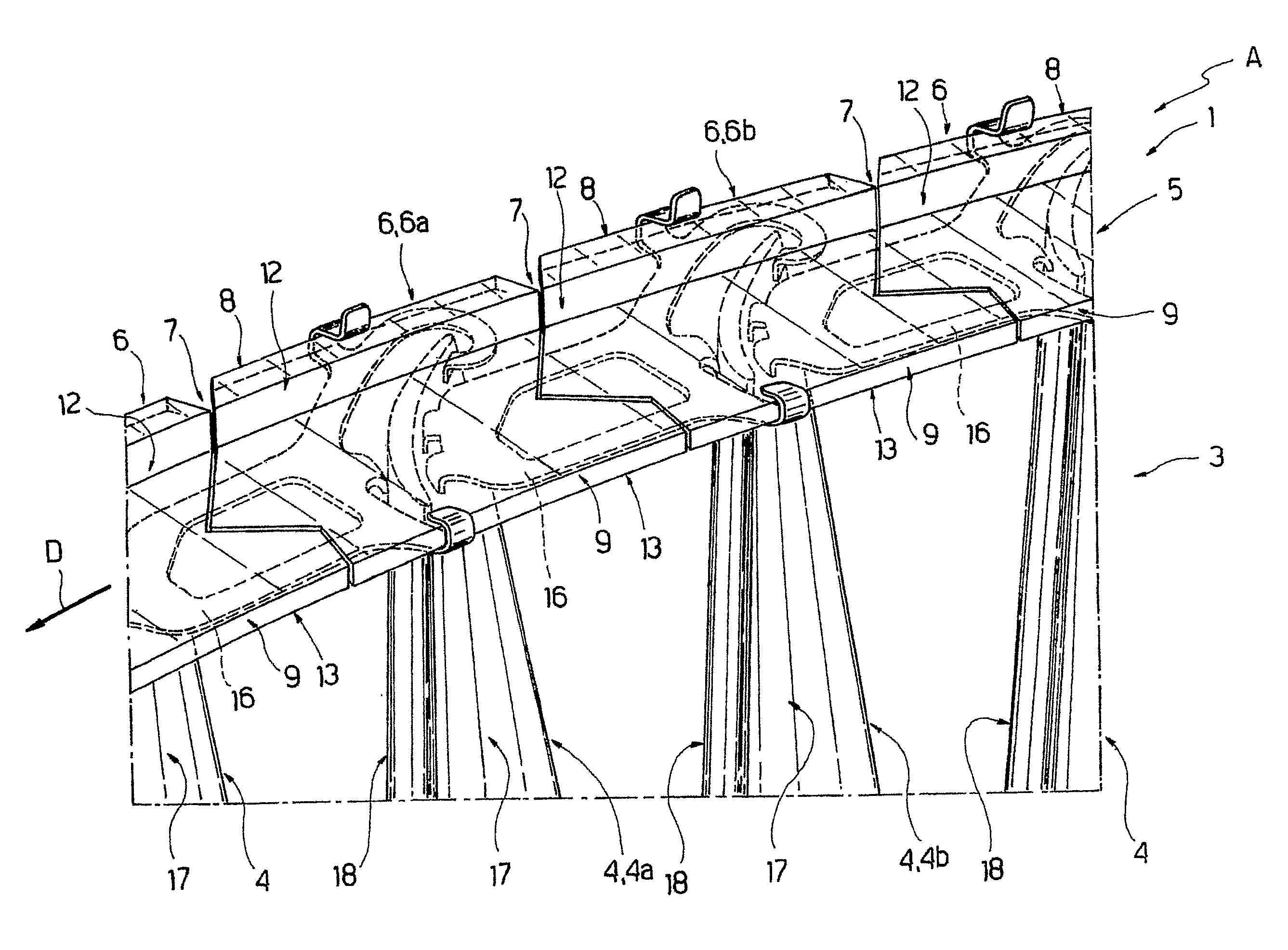

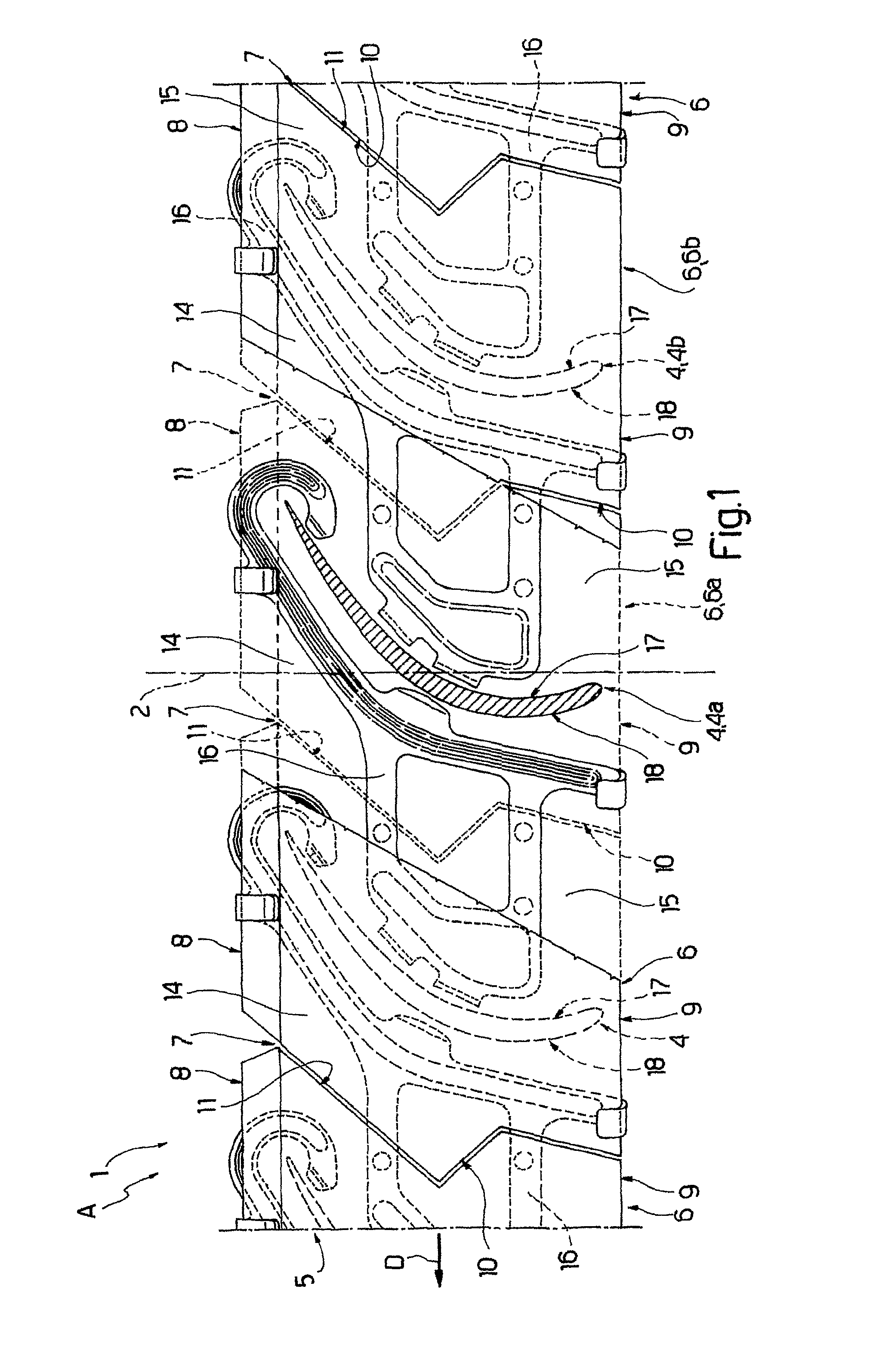

Rotor For Turbomachines With Shrouded Blades

ActiveUS20120087794A1Reduces and eliminate vibrationReduce and eliminate vibrationPropellersPump componentsMechanical engineering

A rotor for turbomachines with shrouded blades comprising a row of a plurality of blades covered by an external ring, coaxial to said row of blades; the external ring being composed of a plurality of sectors, commonly referred to as shrouds, which are adjacent to one another and transversely and circumferentially attached to the end of respective blades; a damping member being arranged so as to straddle a respective pair of adjacent sectors and being pushed, in use, against radially internal surfaces of the sectors of the pair of adjacent sectors.

Owner:GE AVIO

Power Tool

ActiveUS20200070265A1Reduce or eliminate vibrationVibration arisesMetal sawing devicesPortable percussive toolsPhysicsPower tool

Owner:BOSCH POWER TOOLS CHINA +1

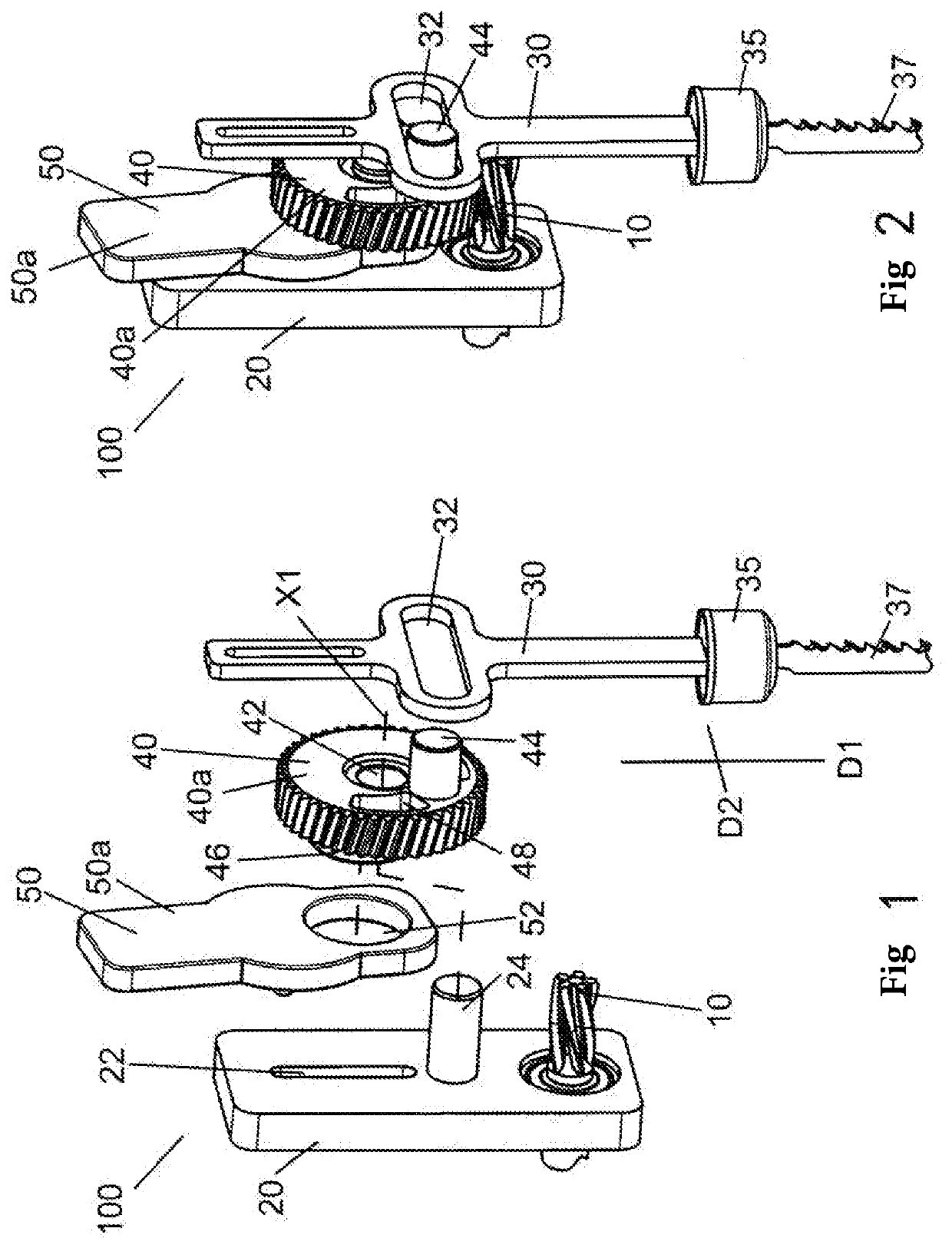

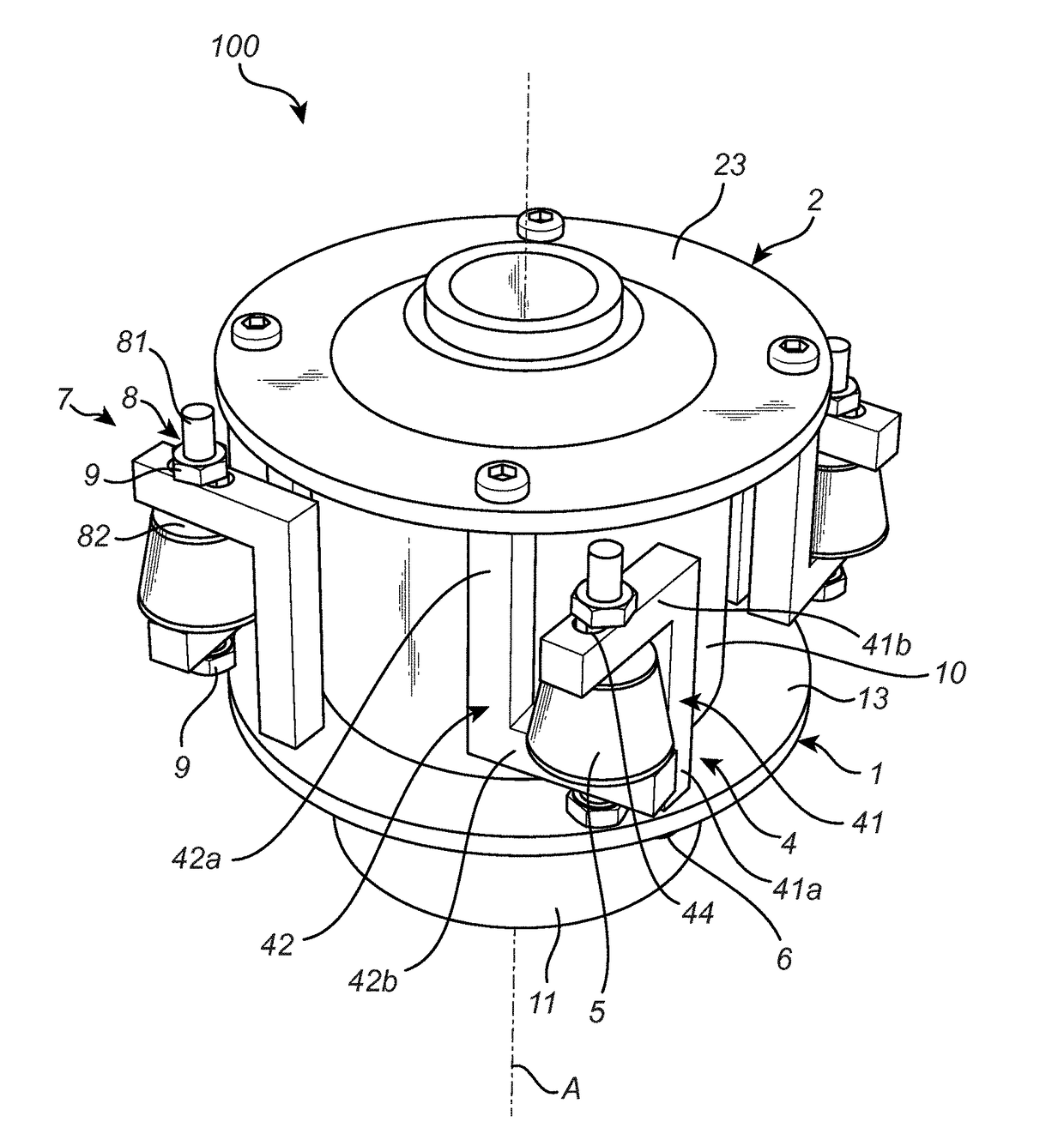

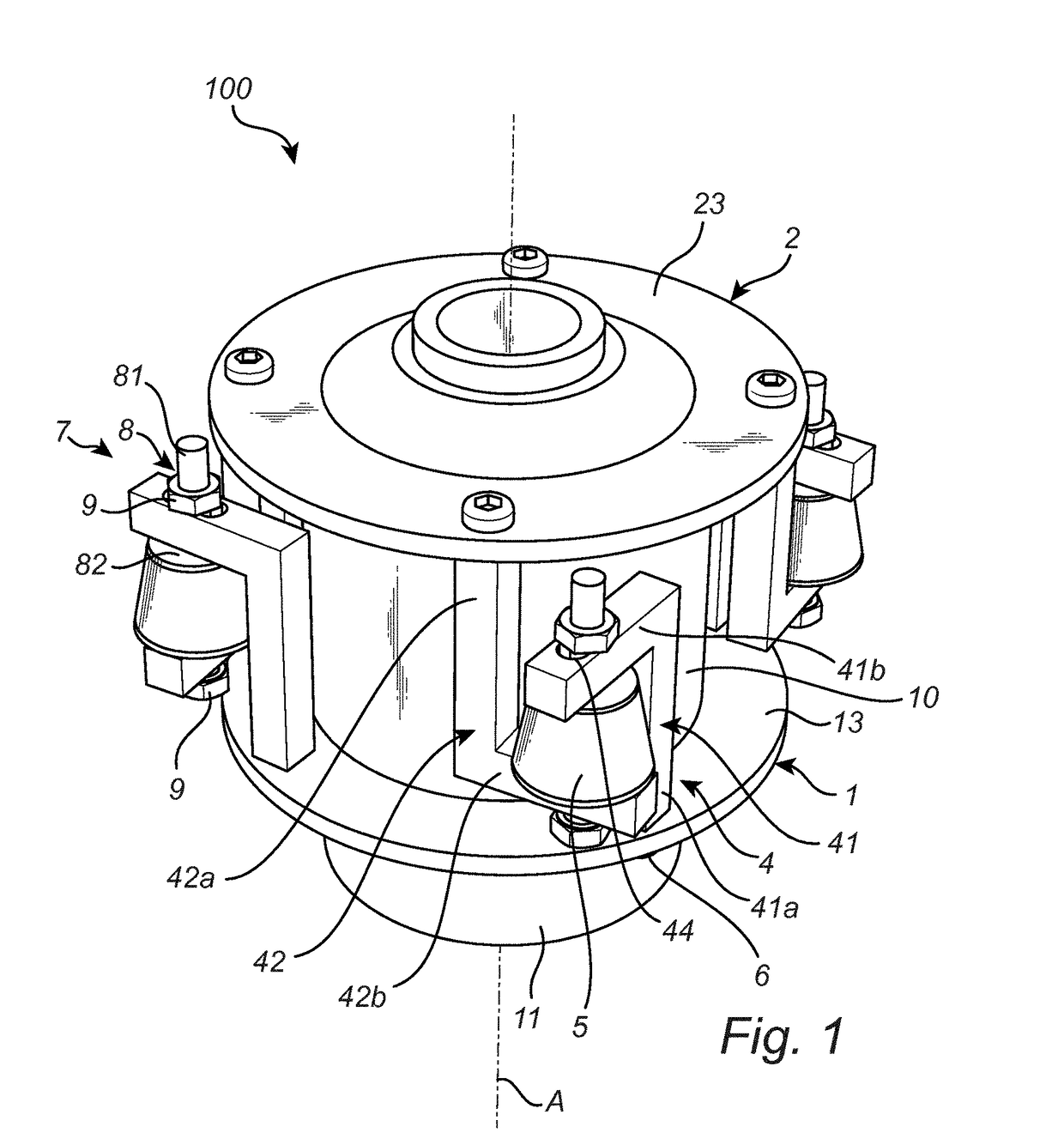

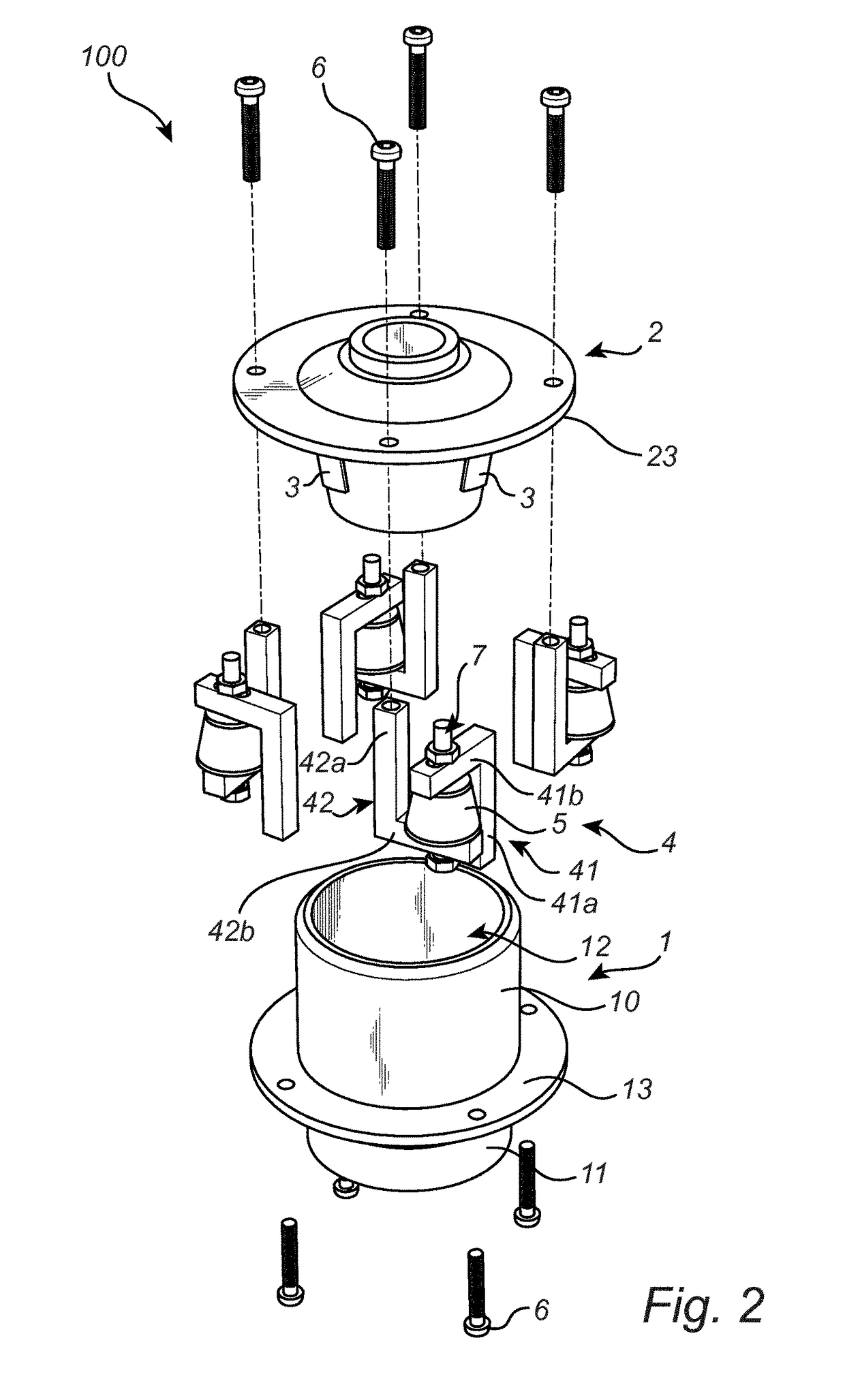

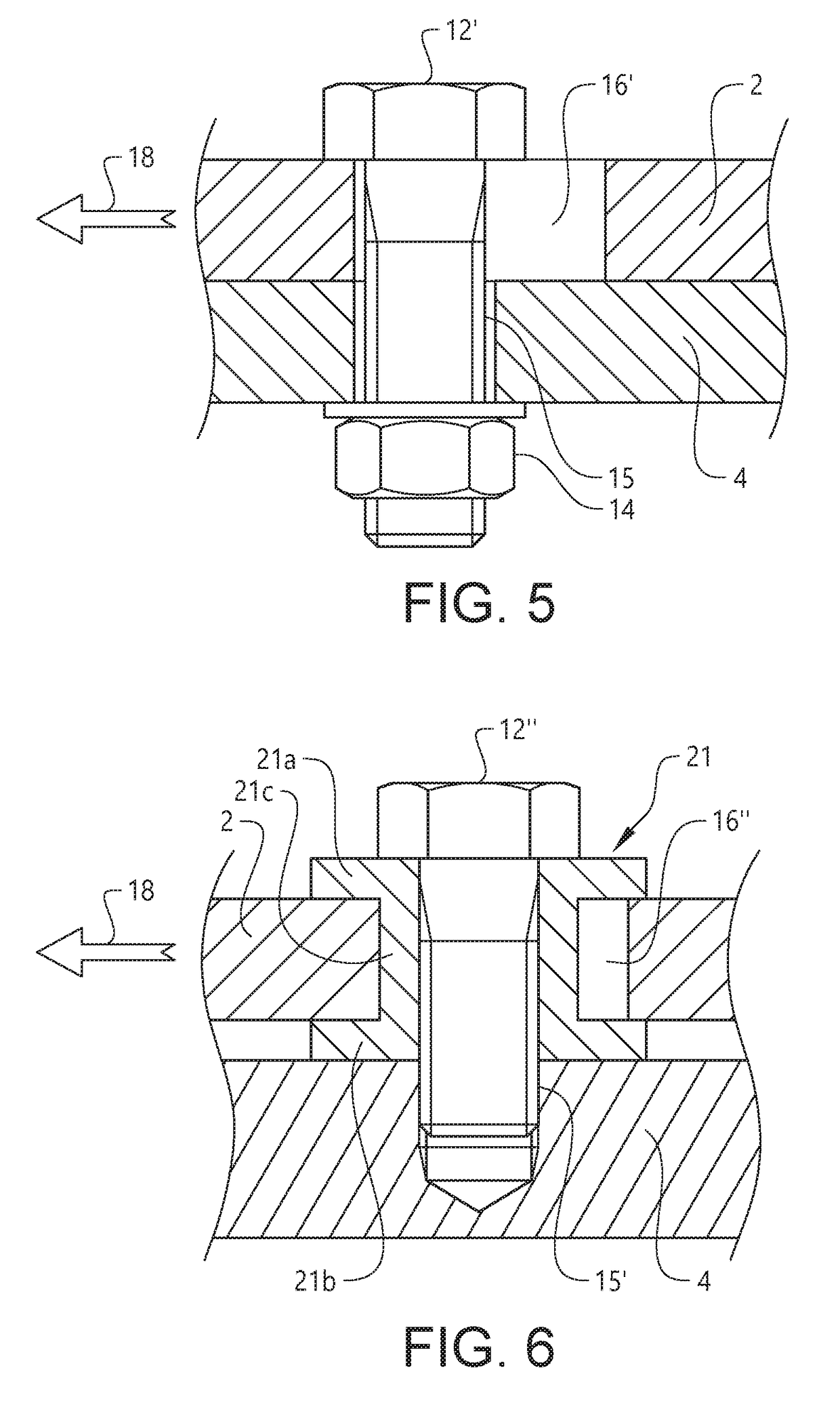

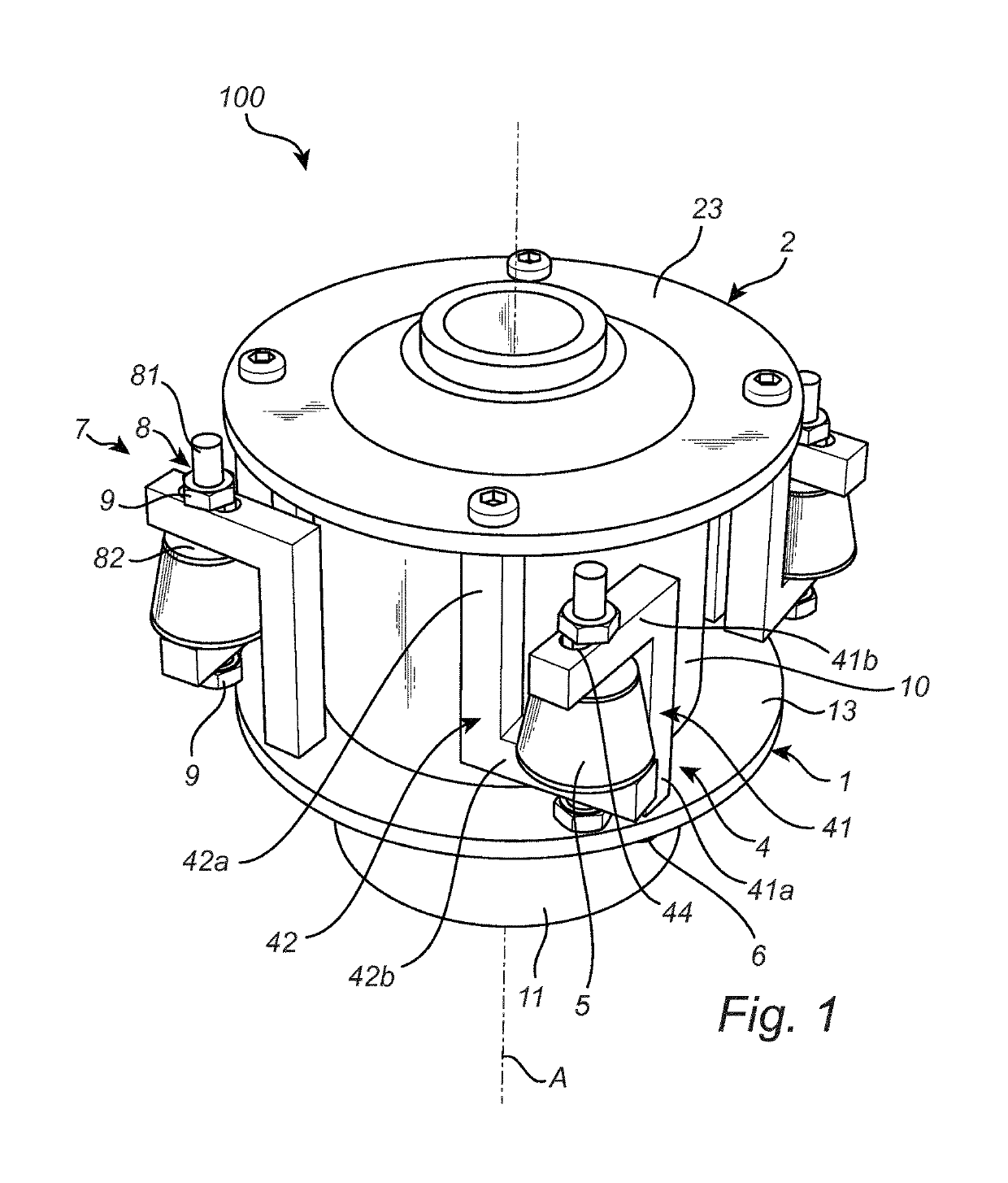

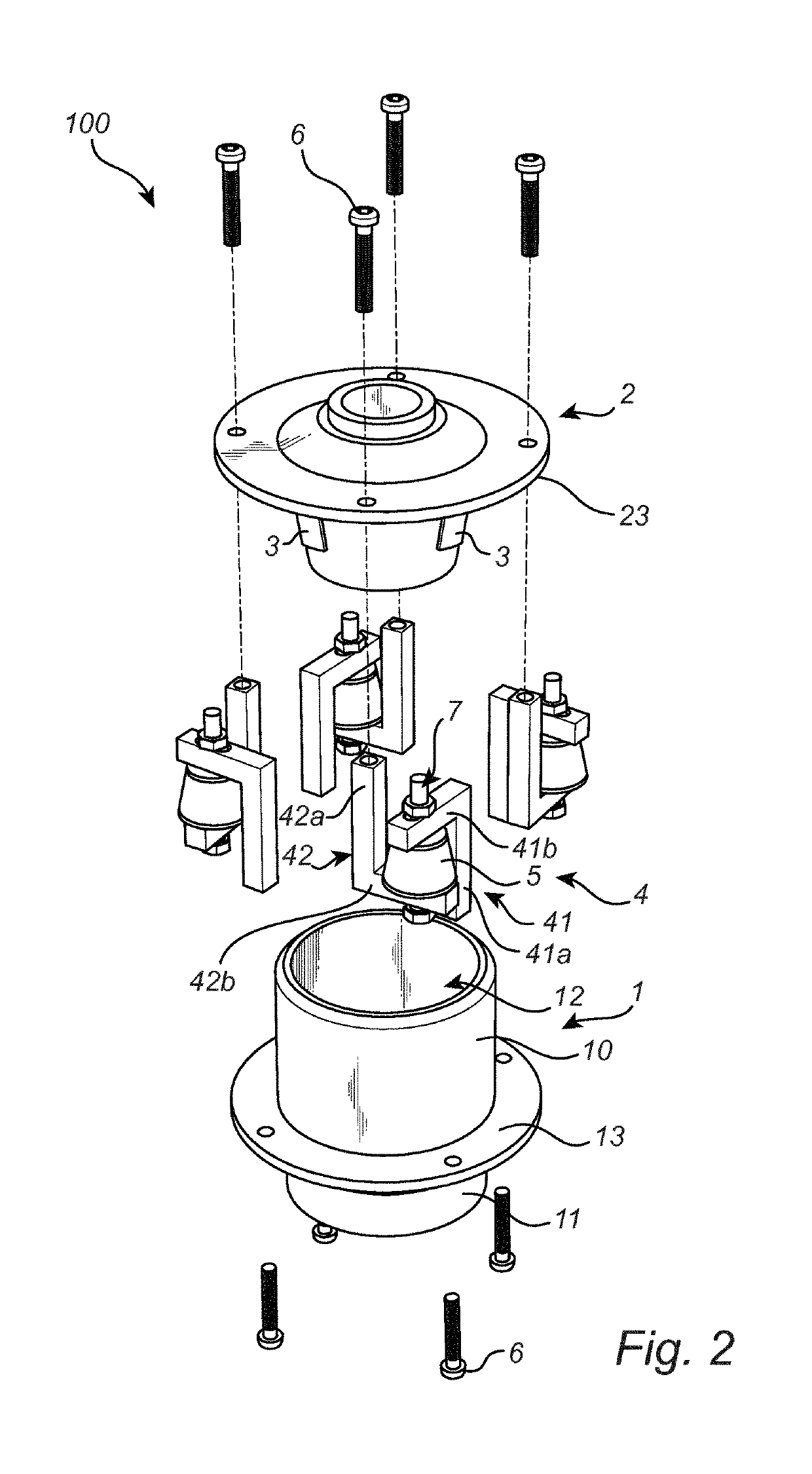

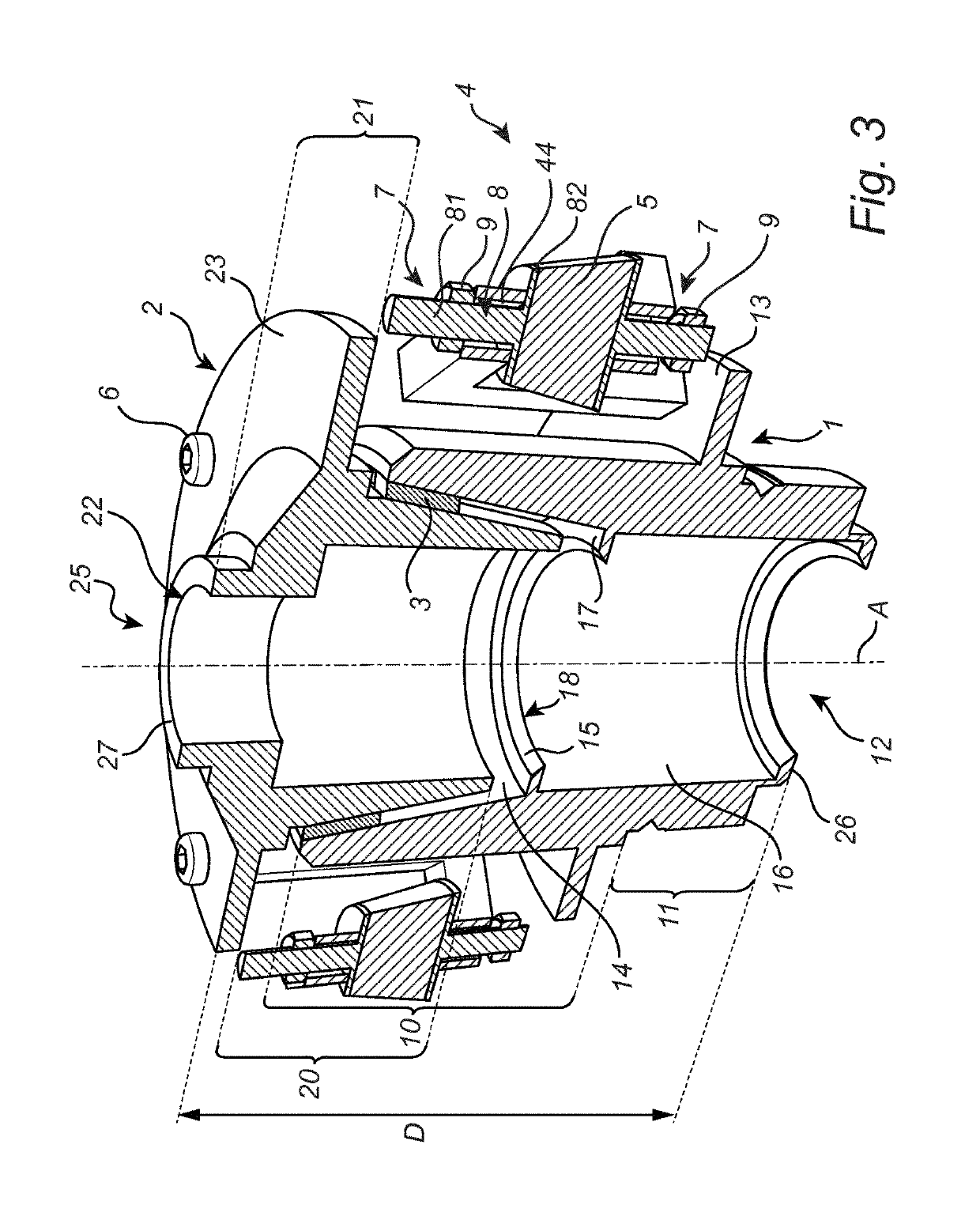

A vibration damping connector and use of the vibration damping connector

ActiveUS20180231794A1Reduce and eliminate vibrationQuality improvementSpringsVibration dampersEngineeringMechanical engineering

The present invention refers to a vibration damping connector (100) for reducing vibrations between a vibration prone system and an optical imaging system, said vibration damping connector comprising a first part (1) adapted to be connected to said optical imaging system, a second part (2) adapted to be connected to said vibration prone system, and at least one first shock absorbing element (3), a portion of said first part (1) is arranged inside a portion of said second part (2) along a central axis (A) or a portion of said second part (2) is arranged inside a portion of said first part (1) along a central axis (A) and said at least one flexible shock absorbing element (3) is arranged between said first part (1) and said second part (2), said vibration damping connector (100) further comprises at least one fastening device (4) for fastening said first part (1) to said second part (2) and said fastening device (2) presses said first part(1) to said second part (2) via a second shock absorbing element (5). Furthermore, use of the vibration damping. connector, in an optical system is disclosed.

Owner:INL INT IBERIAN NANOTECHNOLOGY LAB

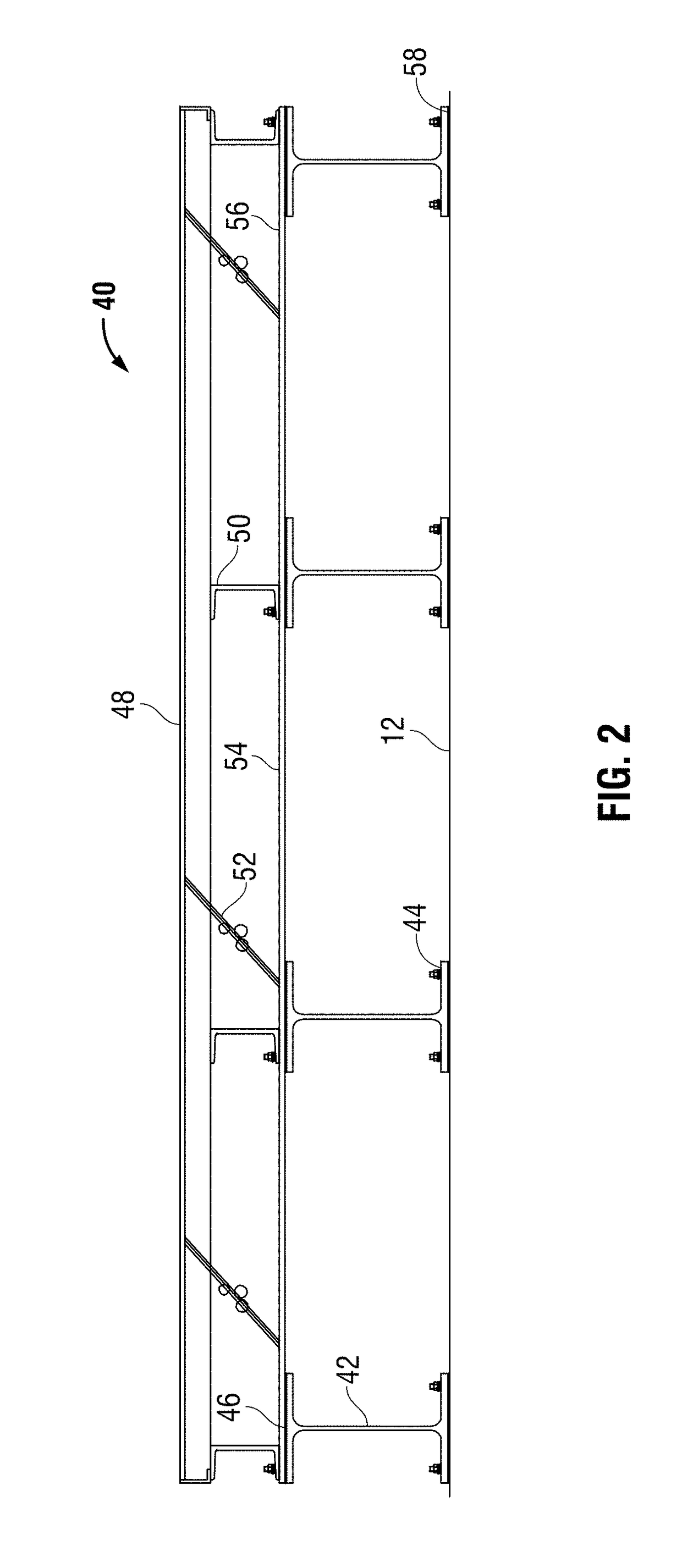

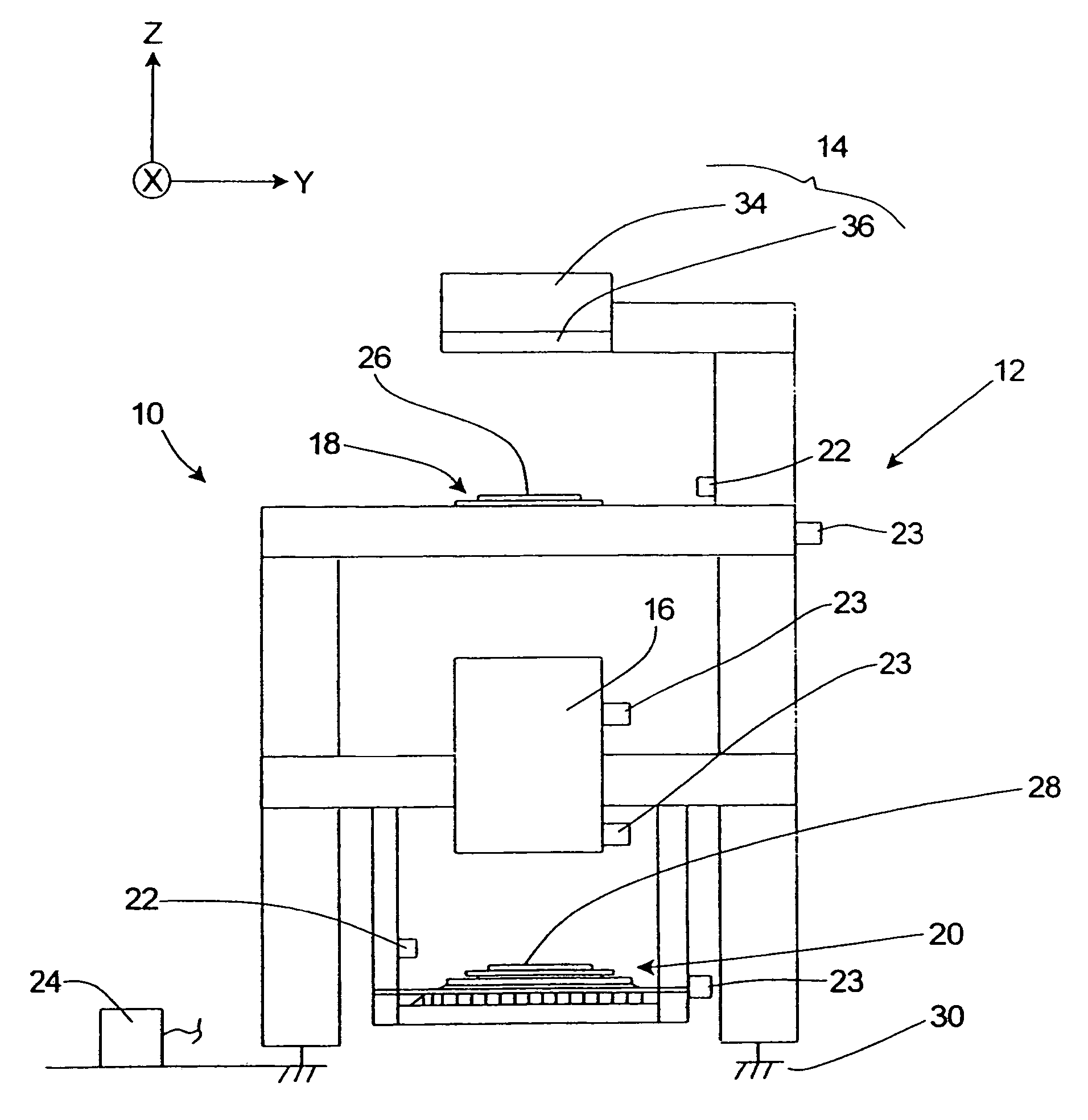

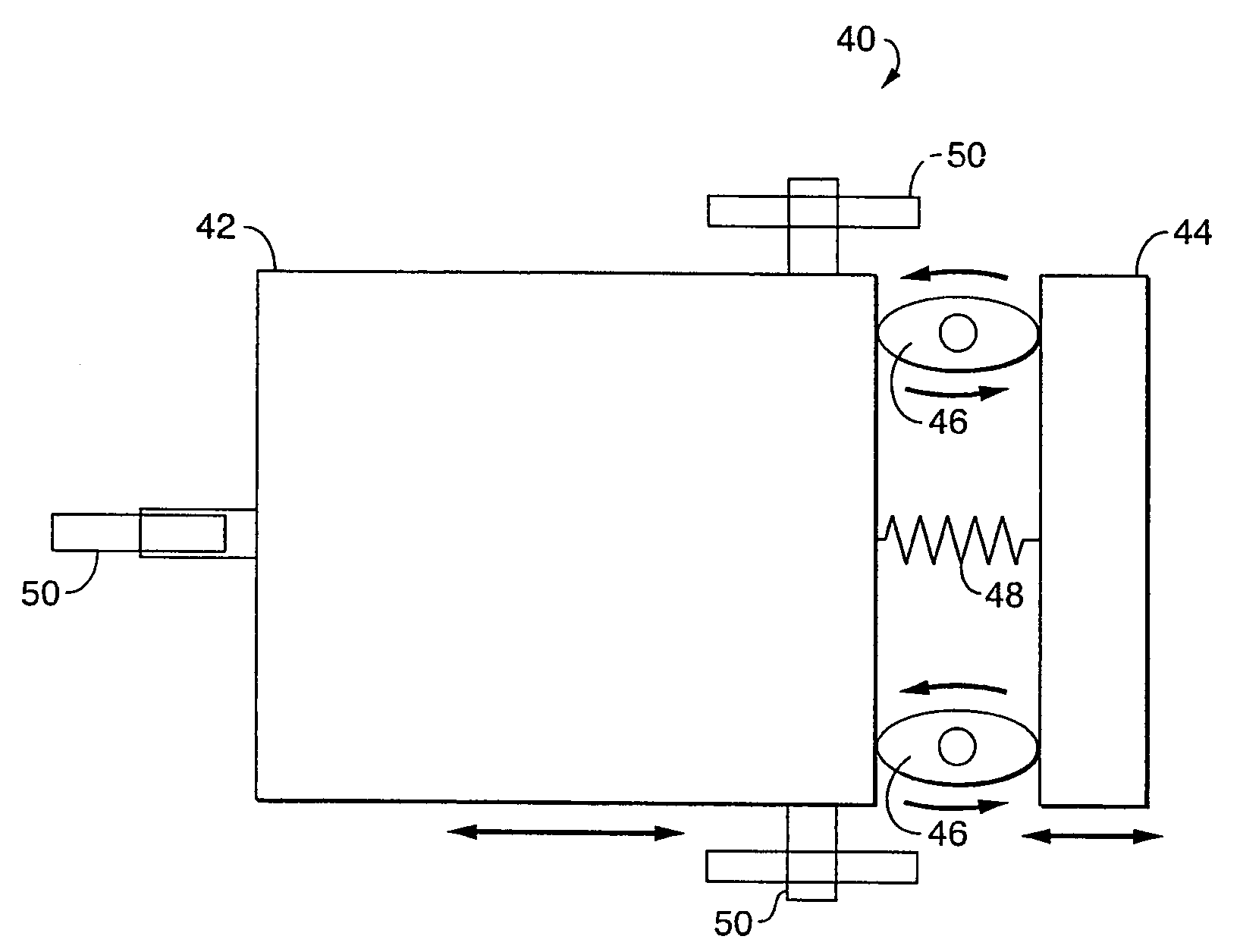

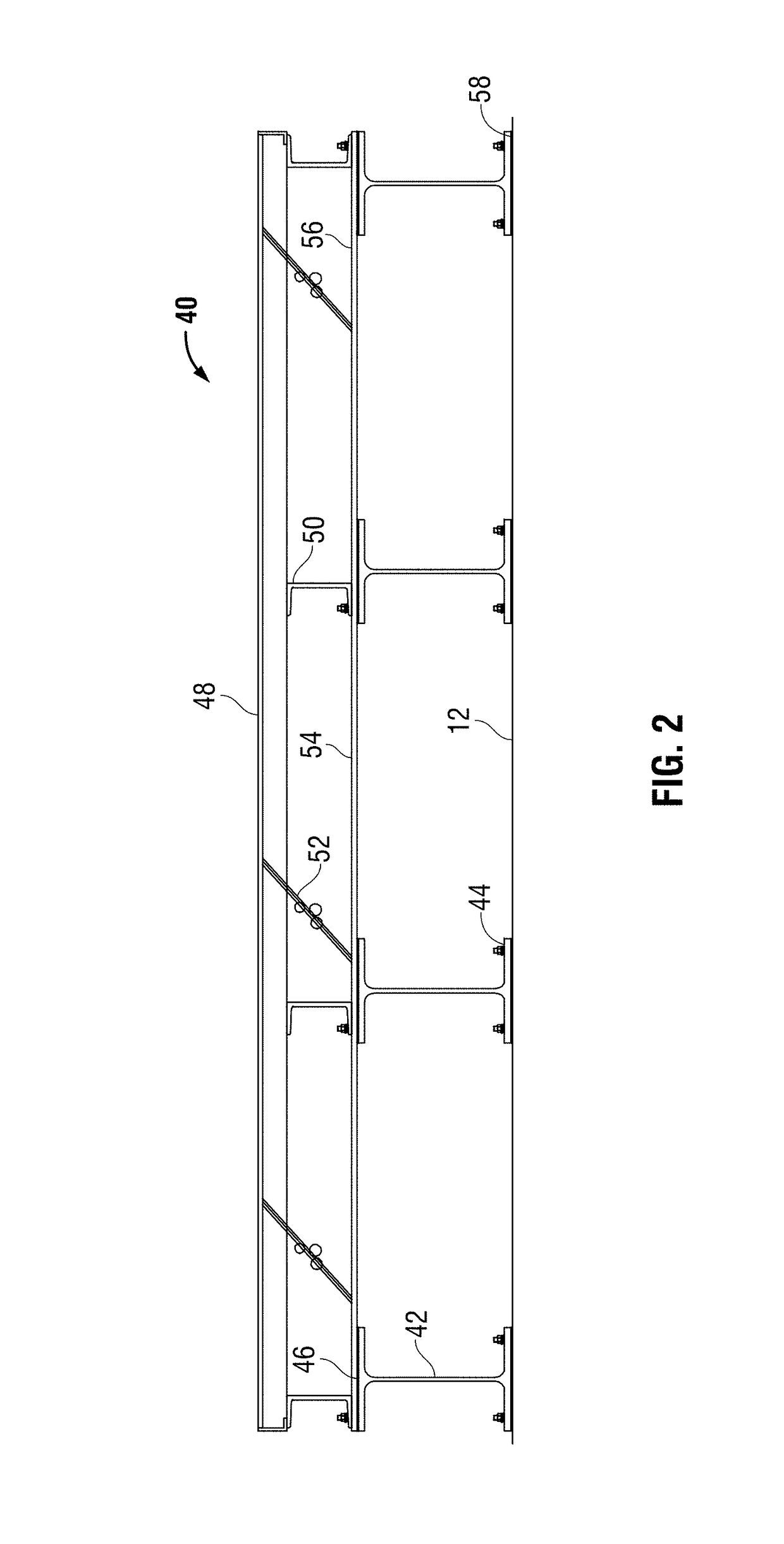

Method and system for improved semiconductor processing equipment vibration isolation and reduction

A method to improve vibration isolation in semiconductor process level inhibits vibration frequencies transmitted though building structure from production tools, pumps, compressors, chillers, AHUs (Air Handling Units), and footfalls traffic on raised floor system on to tool pedestals and pads from affecting semiconductor fabrication processes. Sound proofing material and foam is injected into hollow steel and / or aluminum support members and sound proofing adhesives and / or caulking are applied at points of connections in conjunction with mechanical fastening. In various applications, placement of shaped wielded rod utilized for dissipating vibration energy in center of hollow member which is surrounded with sound proofing material and / or foam. In addition, utilization of this method for dedicated MEP (mechanical, electrical, plumbing) support pedestal, only attach as support for MEP lines, as to improve isolation of low frequency vibration.

Owner:SK COMML CONSTR INC

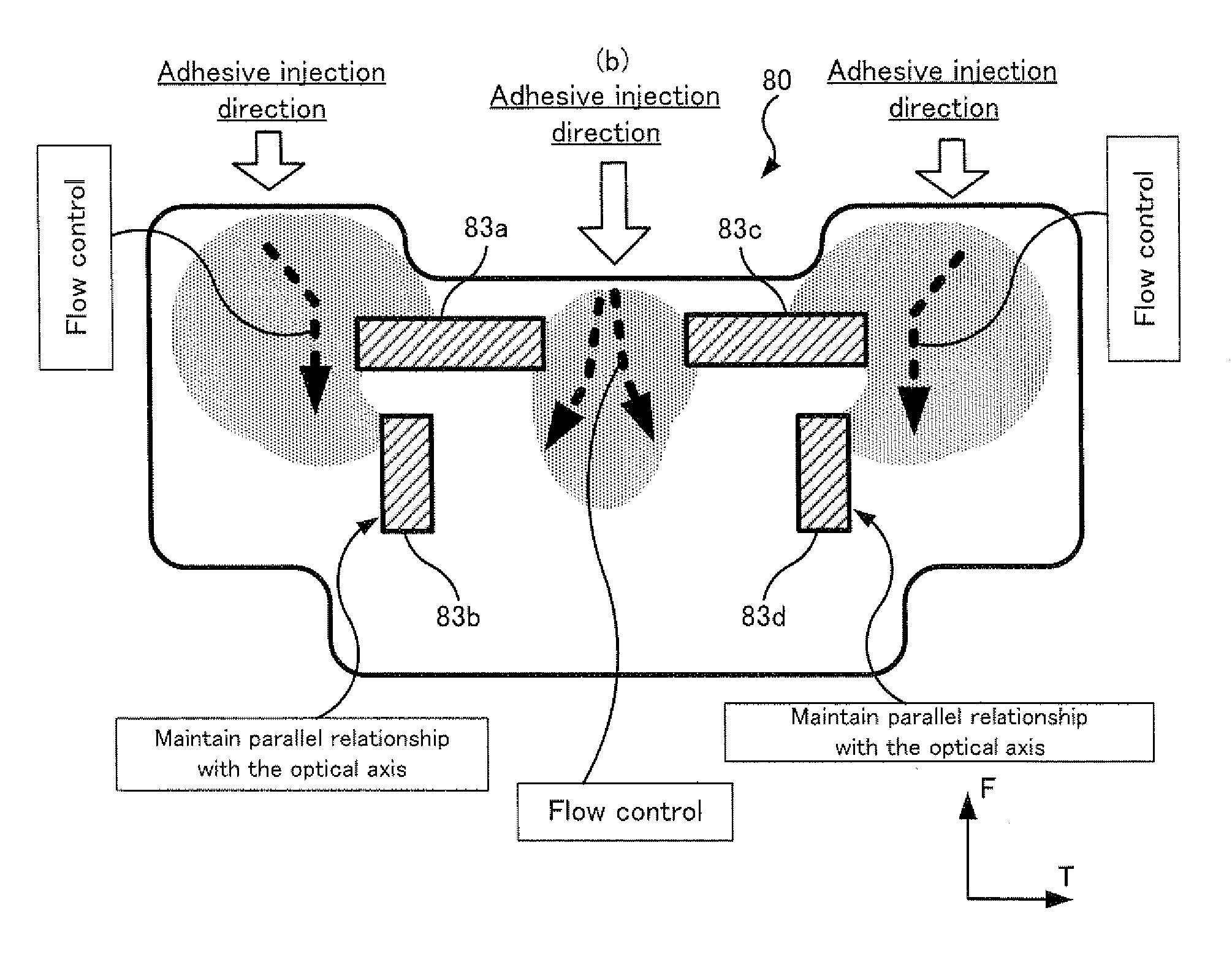

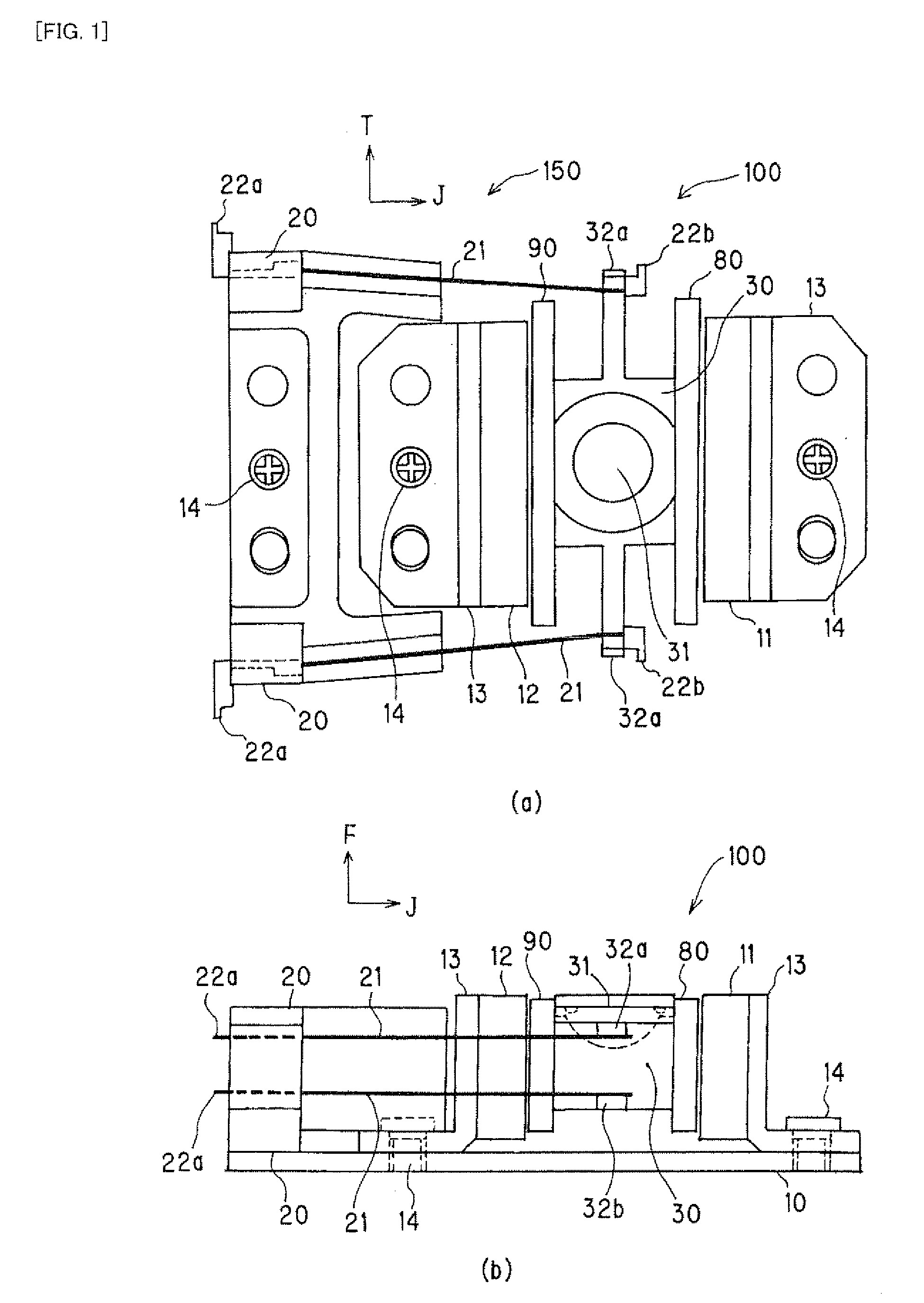

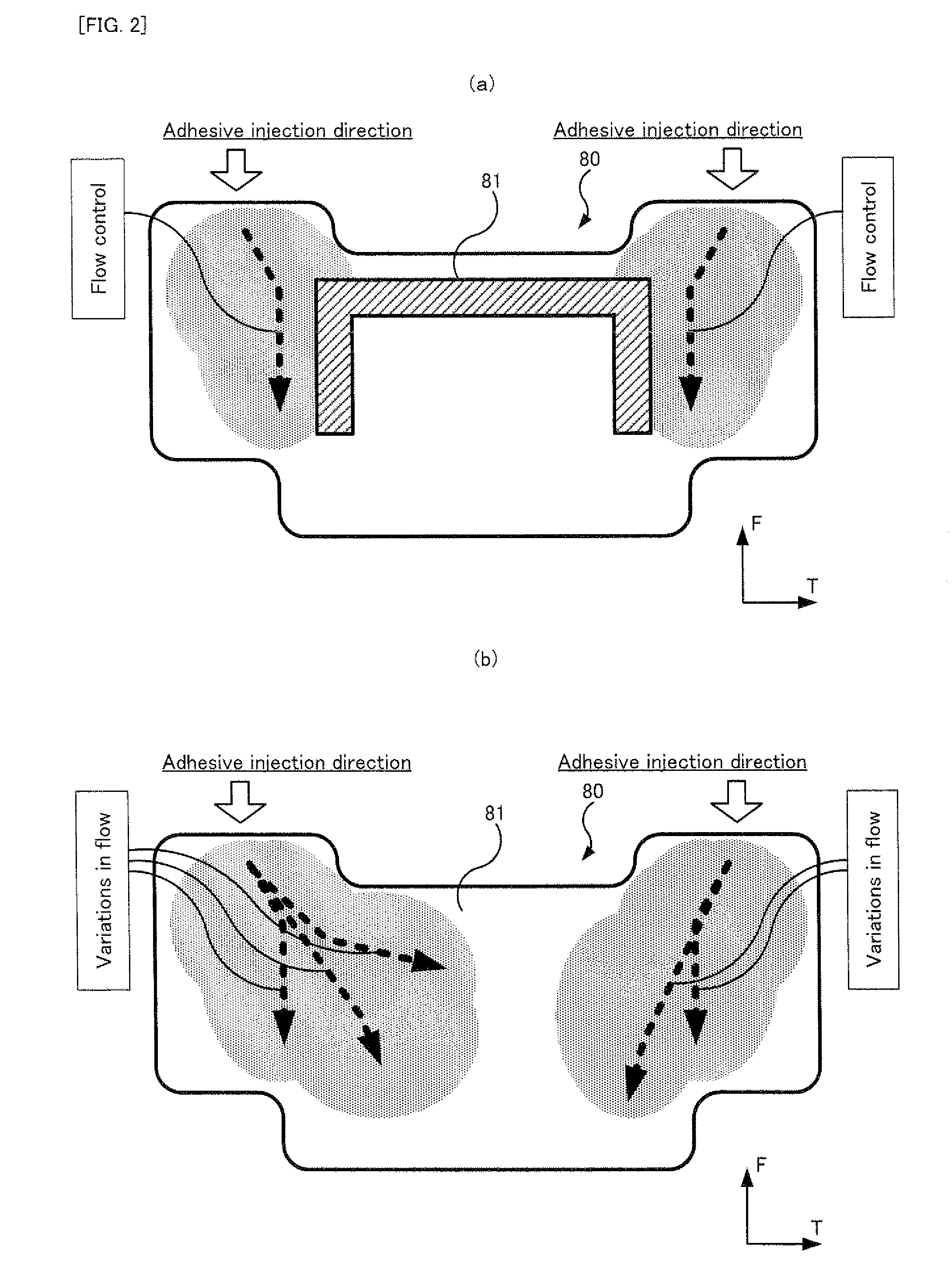

Lens driving apparatus and method of manufacturing the lens driving apparatus

InactiveUS20100007971A1Quality improvementReduce and eliminate vibrationOptical articlesRecord information storageAdhesiveEngineering

A lens drive device has (i) an objective lens and (ii) a lens holder, to a side face of which coils for drive control are attached. The surface where the coils are adhered, or the side surface, is an irregular surface where a recess / projection section for restricting the direction of flow of an adhesive is formed. The coils and the lens holder are integrally formed together by the adhesive with the recess / projection section in between.

Owner:PIONEER CORP

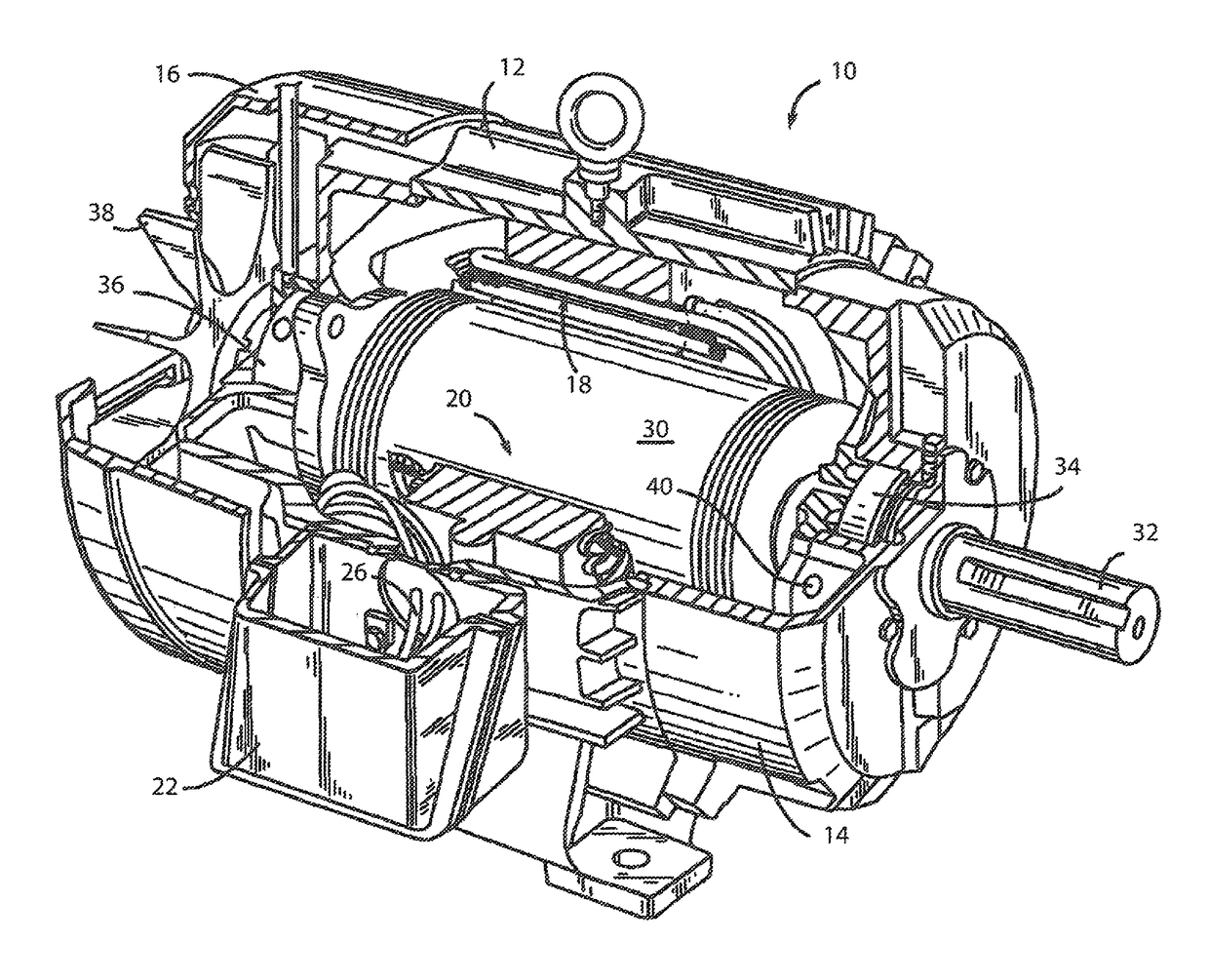

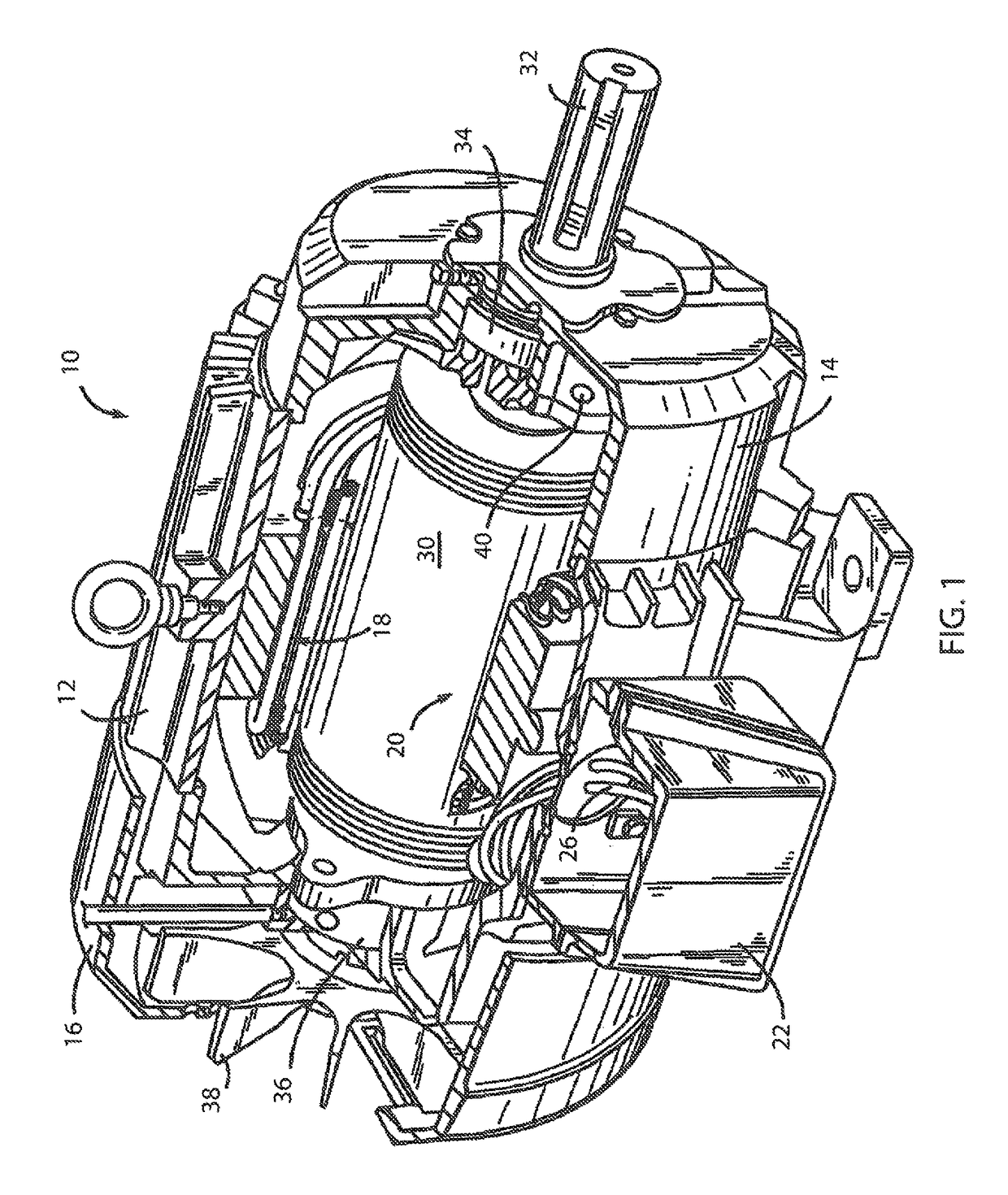

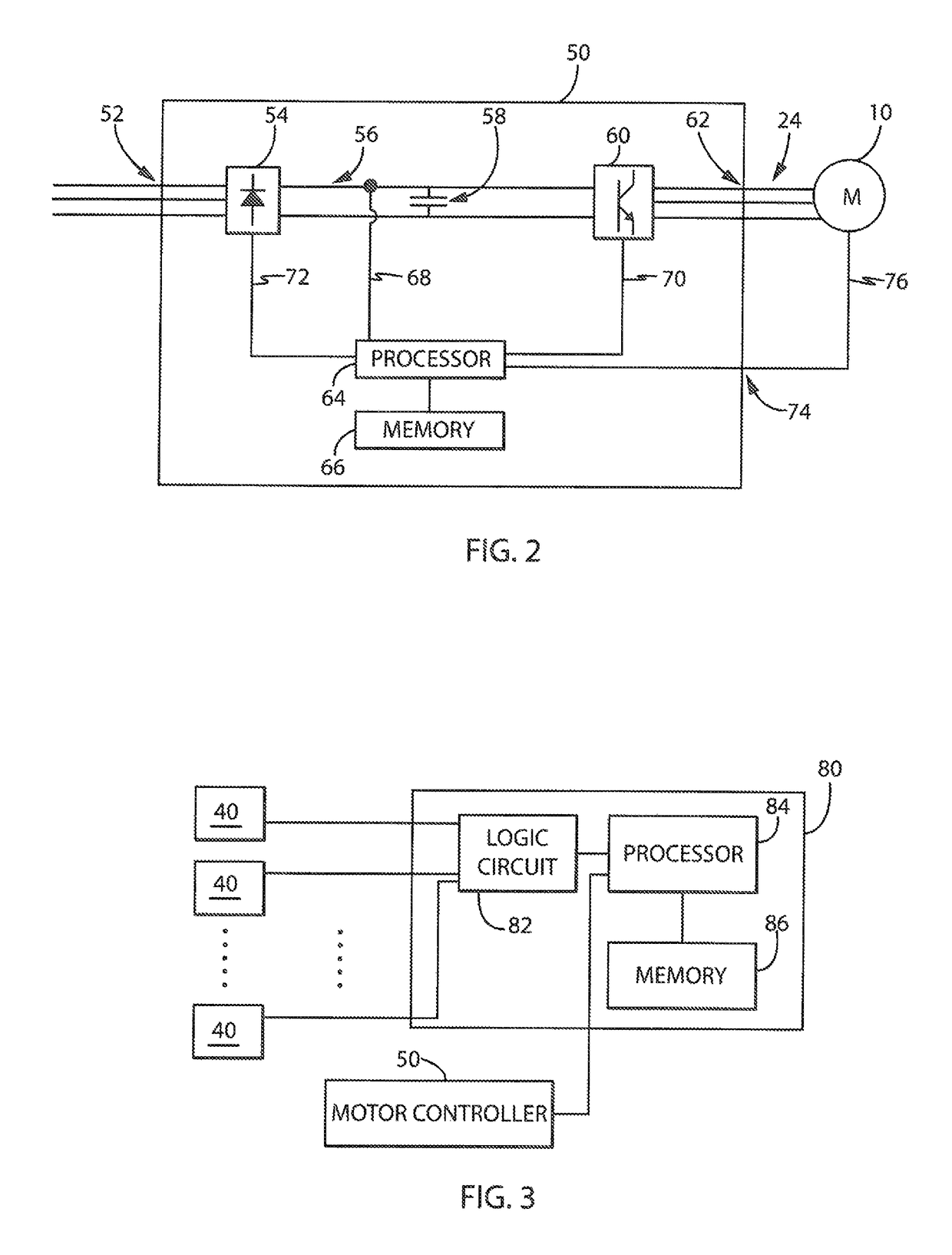

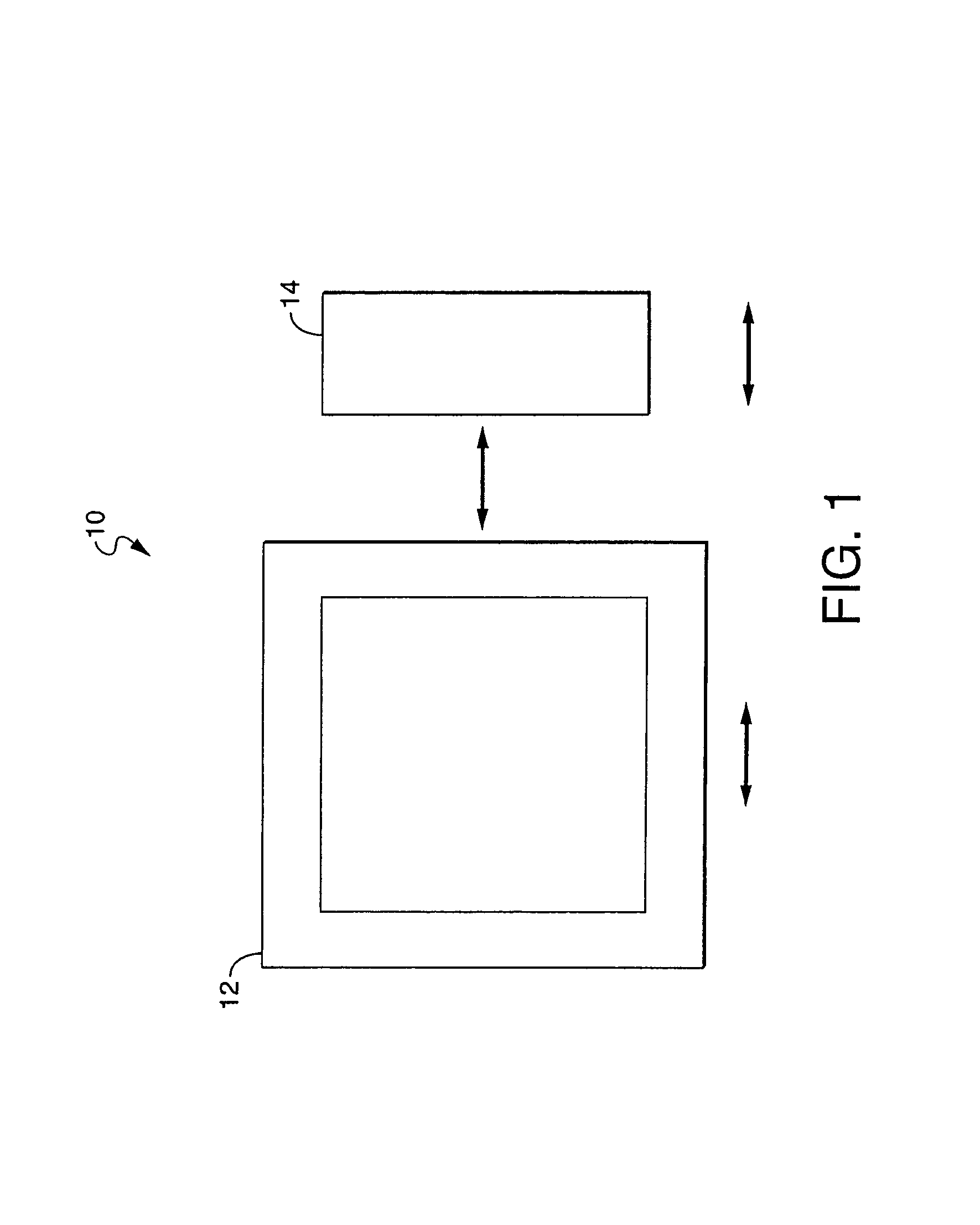

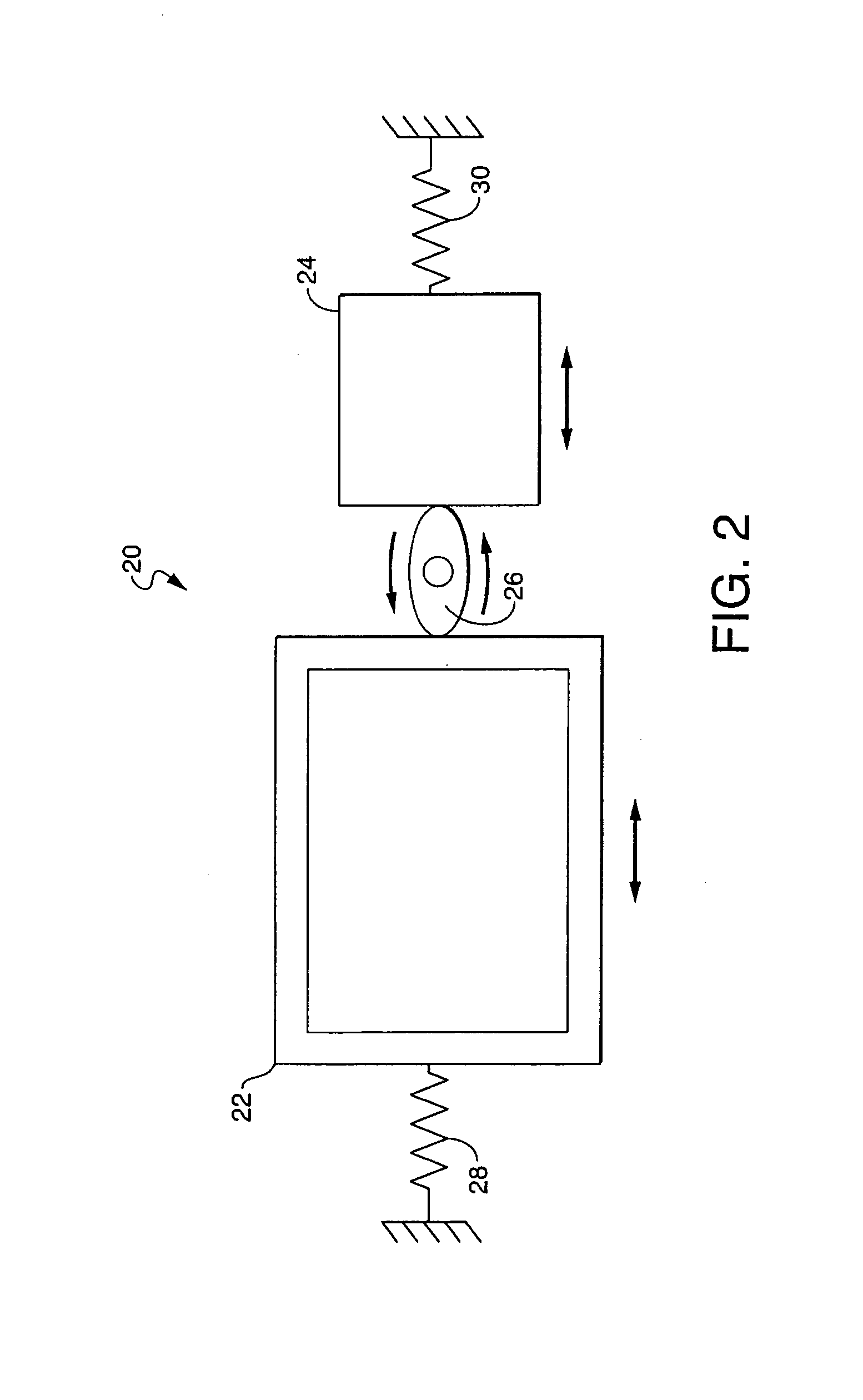

System and method for detection of motor vibration

ActiveUS9673685B2Reduce vibration detectedReduce and eliminate vibrationElectronic commutation motor controlVector control systemsElectric machineMotor vibration

An improved system for monitoring vibration of an electric machine is disclosed. According to one embodiment, sensors are positioned in a plane orthogonal to the motor shaft and each sensor detects vibration along at least one axis of the motor. The sensors are oriented such that the polarity of each sensor is reversed. The pairs of sensors may be used to isolate specific vibrations within the motor. According to another embodiment, a sensor may be mounted directly to the motor shaft. The sensor on the motor shaft directly detects vibrations along the motor shaft. Optionally, a second sensor may be mounted to a fixed location within the motor housing, and the combination of the sensor on the motor shaft and the sensor at a fixed location may be used to isolate specific vibrations within the motor. A motor controller may adjust operation of the motor to reduce the isolated vibration.

Owner:ROCKWELL AUTOMATION TECH

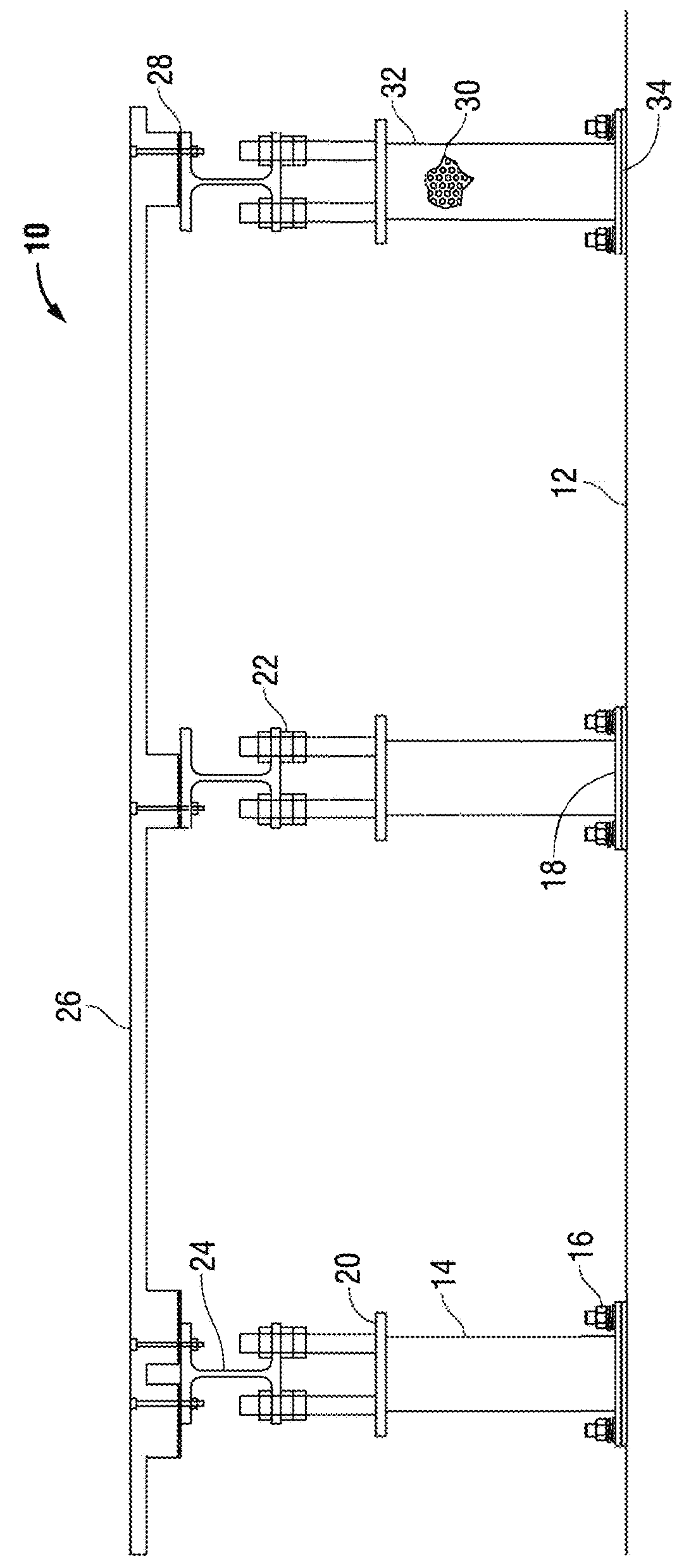

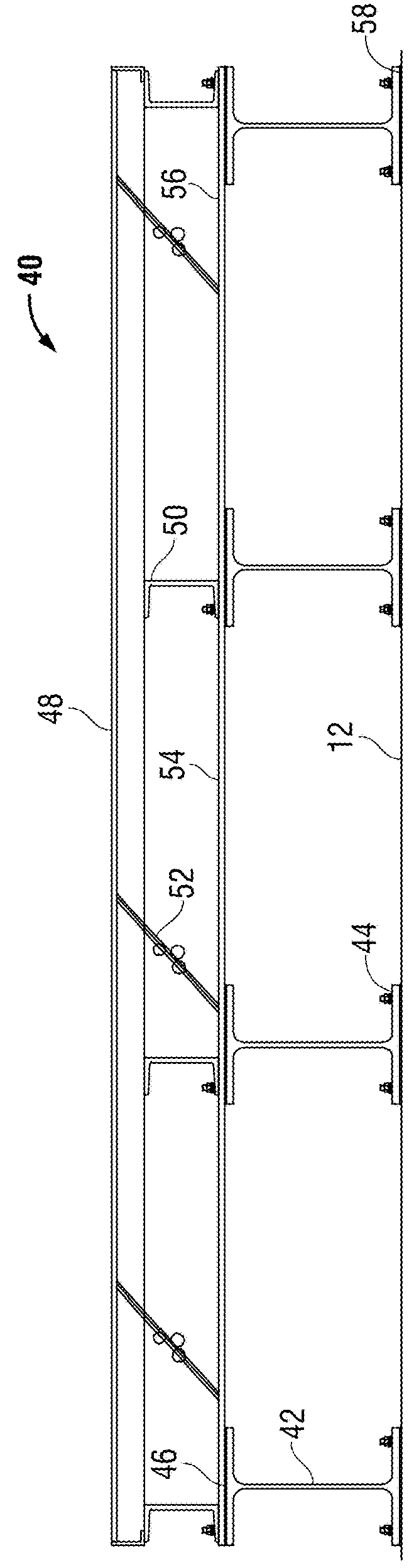

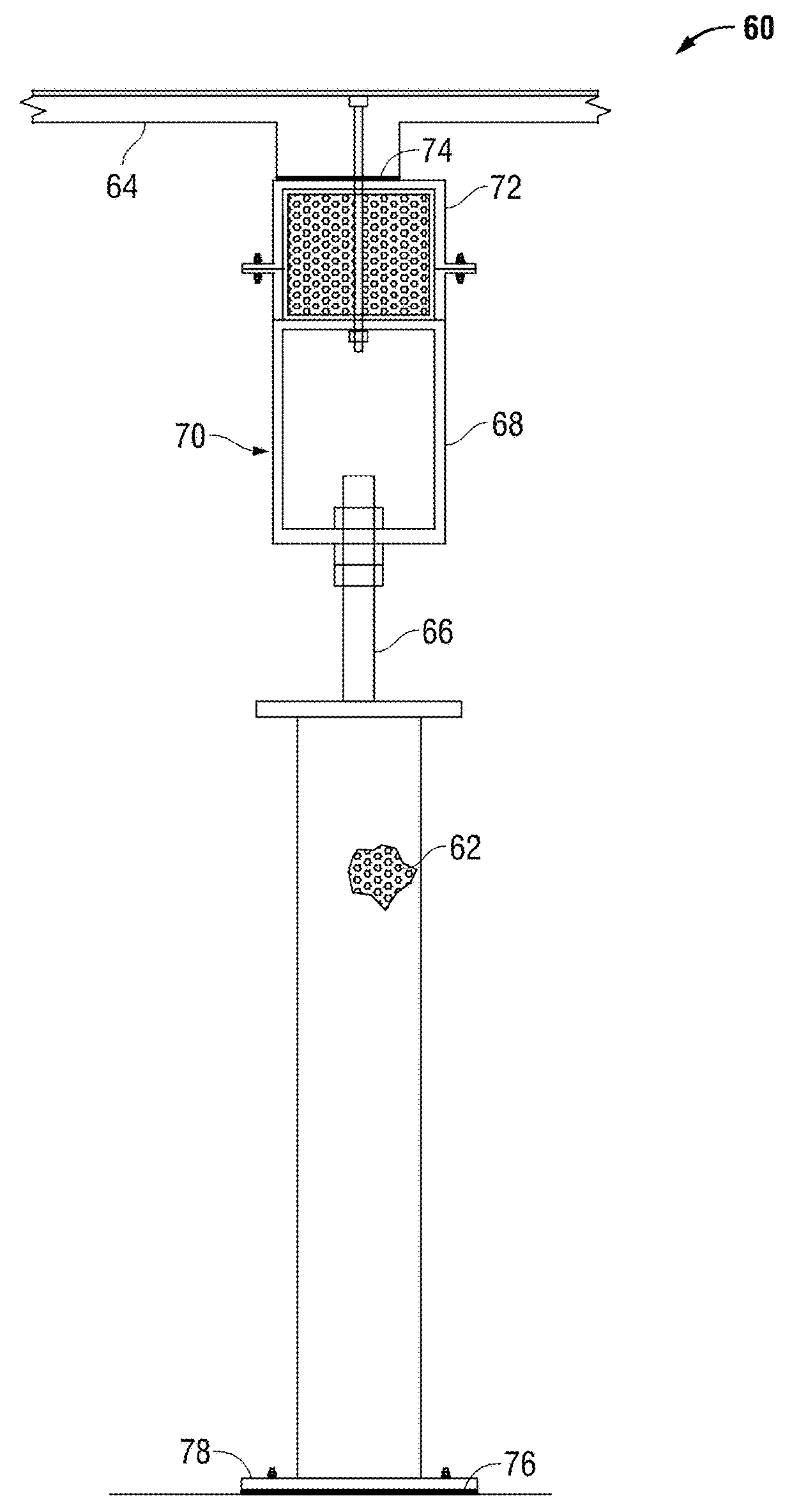

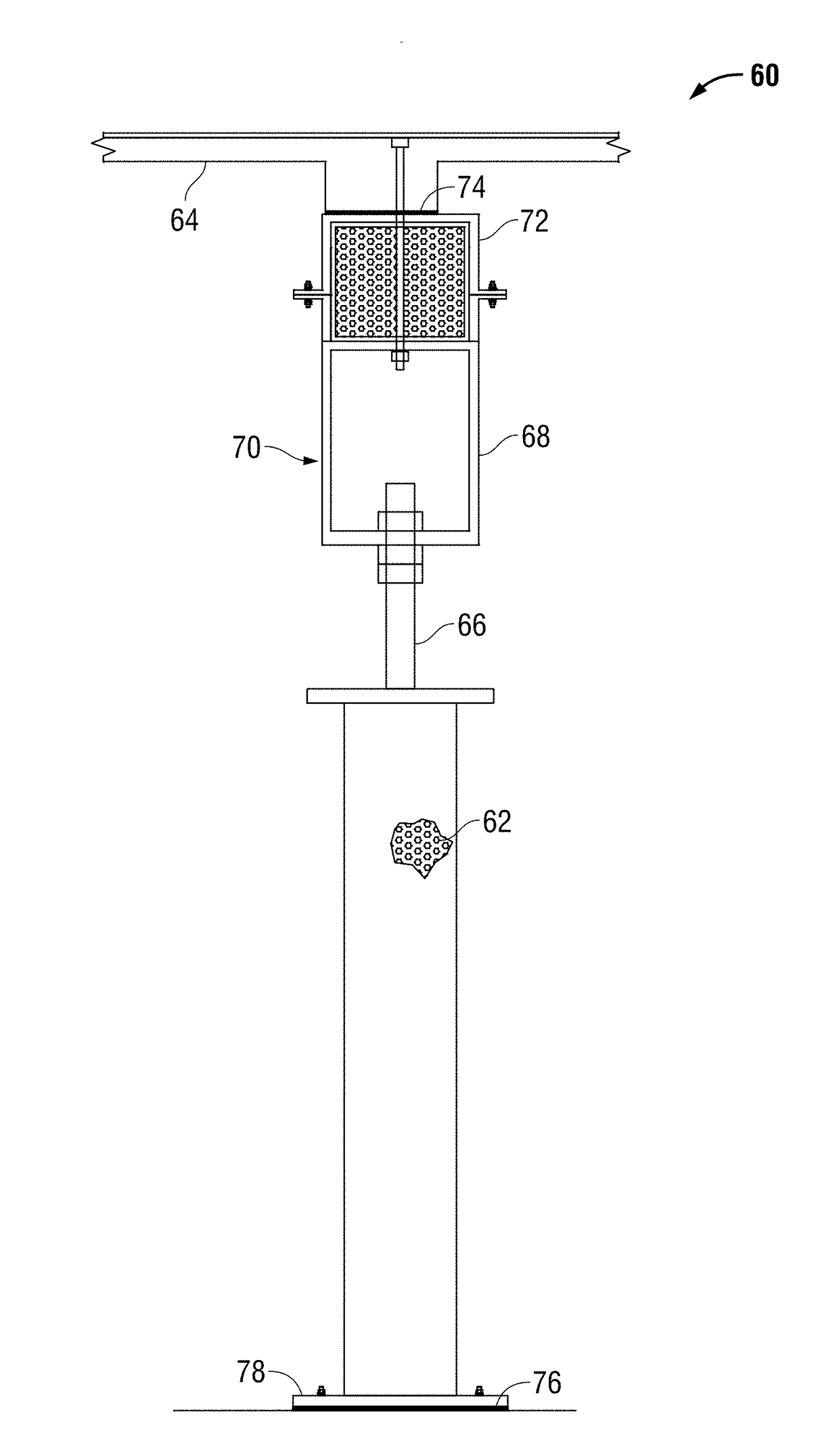

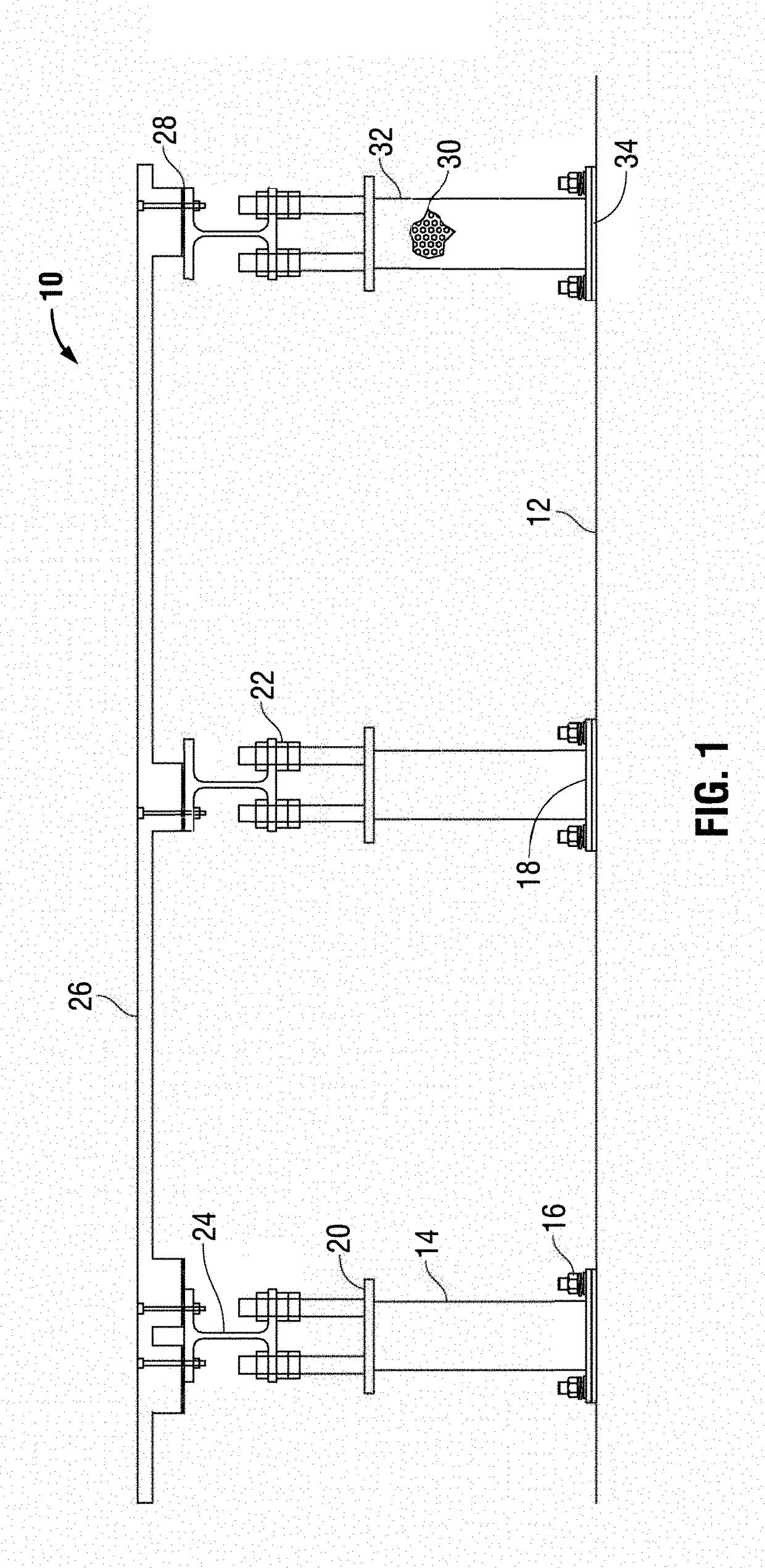

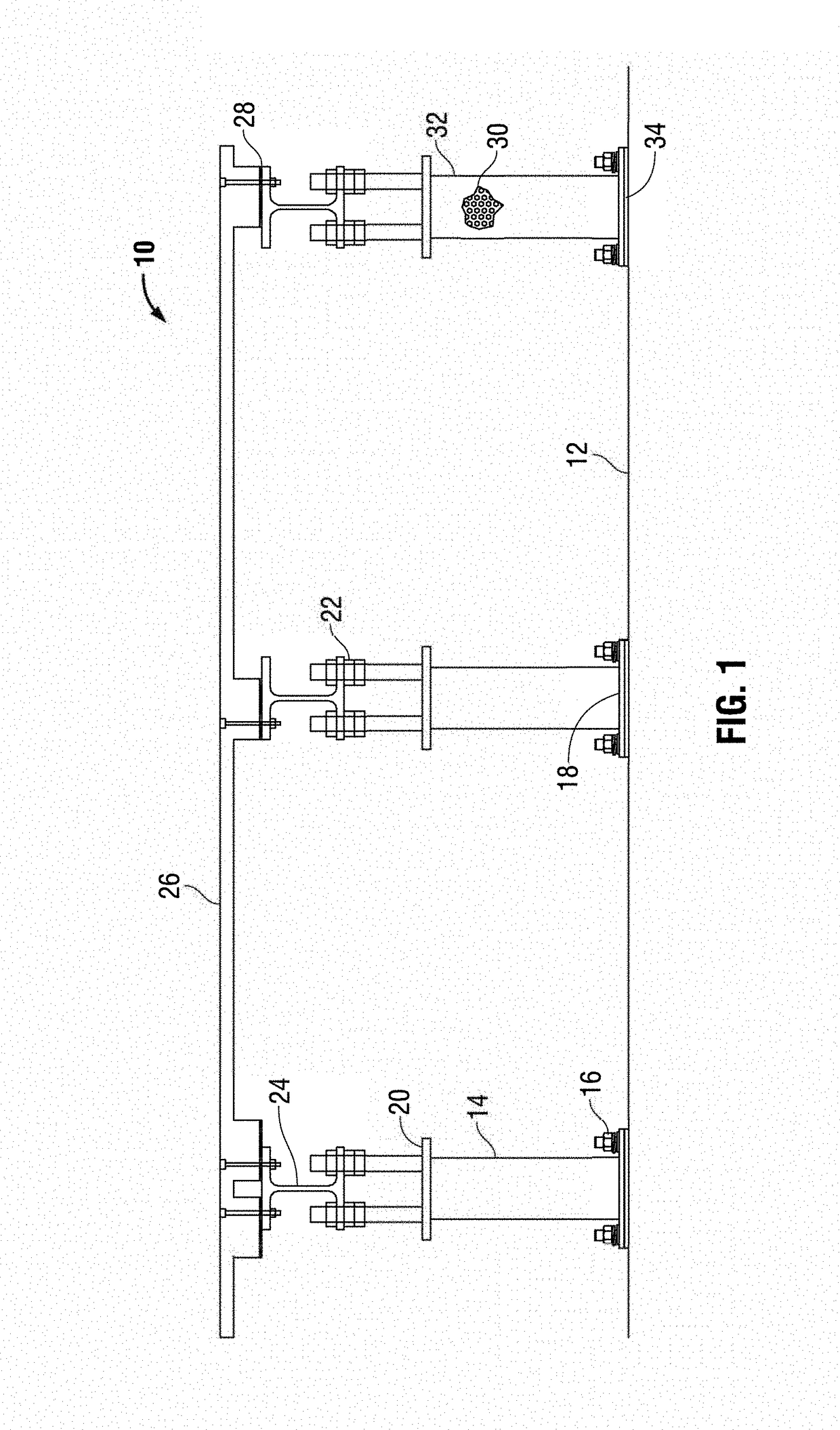

Method for improved semiconductor processing equipment tool pedestal / pad vibration isolation and reduction

ActiveUS20180283486A1Easy to controlImprove protectionNon-rotating vibration suppressionFloorsAir treatmentElectromagnetic interference

A method to improve vibration isolation in semiconductor process level inhibits vibration frequencies transmitted through building structure from production tools, pumps, compressors, chillers, AHUs (Air Handling Units), and footfalls traffic on raised floor system on to tool pedestals and pads from affecting semiconductor fabrication processes. Rapid advancement and technological evolution in semiconductor industry foresee the imminent requirements for decrease in semiconductor chip node sizes to single digit nanometer. Dealing with such advancements, the tool pedestal systems are also requiring tighter specifications for stiffness and vibration isolation / reduction. Some key tools used in the semiconductor fabrication process require improved barrier from electromagnetic interference (EMI), as the disturbance from EMI degrade the performance of semiconductor processing tools that are key to the fabrication process and production yield rate.

Owner:SK COMML CONSTR INC

Vehicle incorporating a deformable front frame structure

ActiveUS20190054875A1Inhibit transferReduce frictionPedestrian/occupant safety arrangementElectric propulsion mountingDrive wheelEngineering

A vehicle, including: an electric motor operatively connected to at least one driving wheel of the vehicle, and a frame structure including first and second side members extending in a longitudinal direction along opposite sides of the vehicle and at least one cross member extending in a transversal direction of the vehicle and being connected to the first and second side members, wherein the electric motor is supported by the frame structure such that the electric motor is arranged in a front portion of the vehicle in association with a pair of front wheels of the vehicle, and wherein each of the side members, at least along a deformable section thereof, is configured to deform by bending in an inwards and / or outwards transversal direction when compressed by a longitudinally directed force exceeding a threshold value, such as in case the vehicle is subject to a sufficiently energetic frontal collision.

Owner:VOLVO CAR CORP

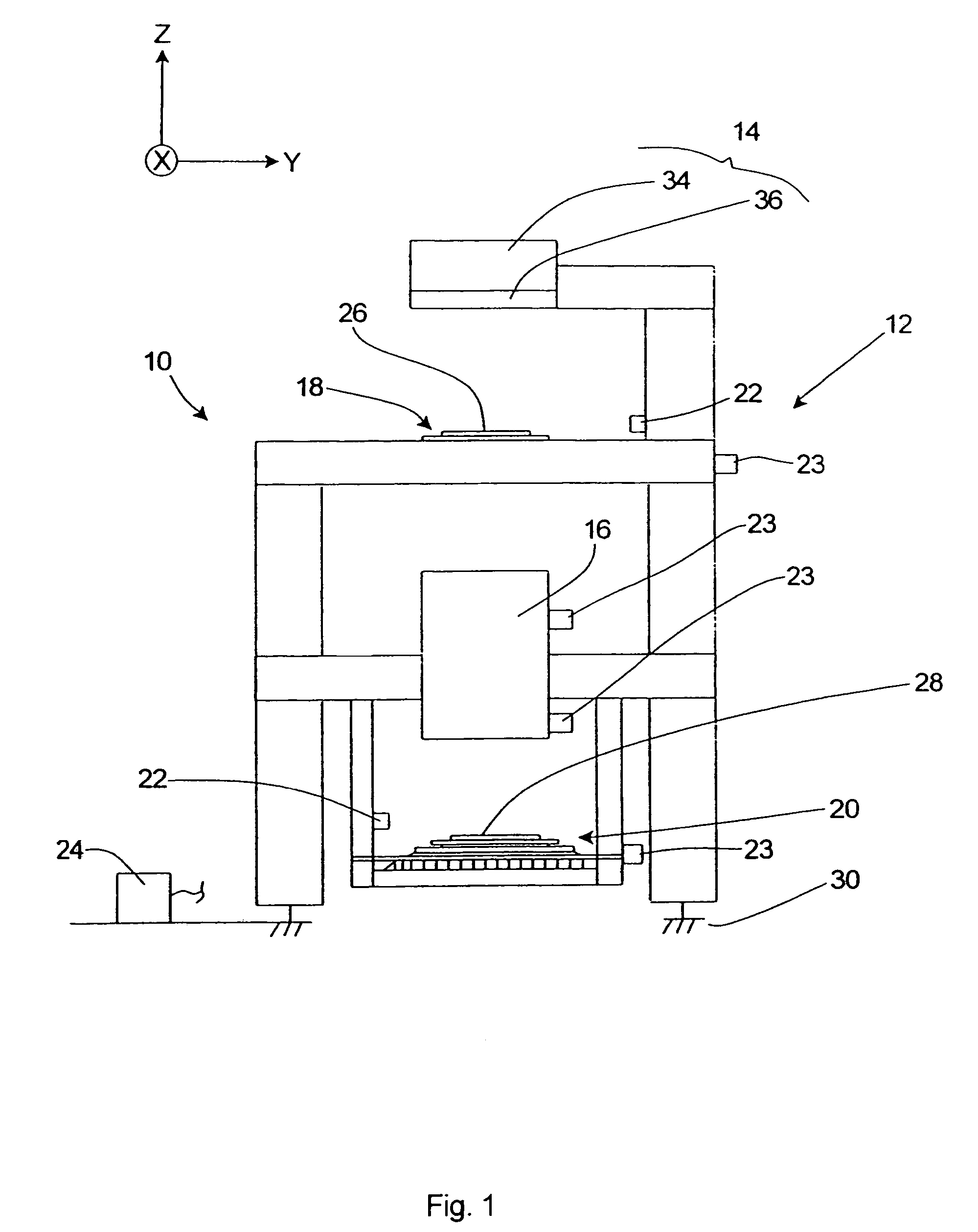

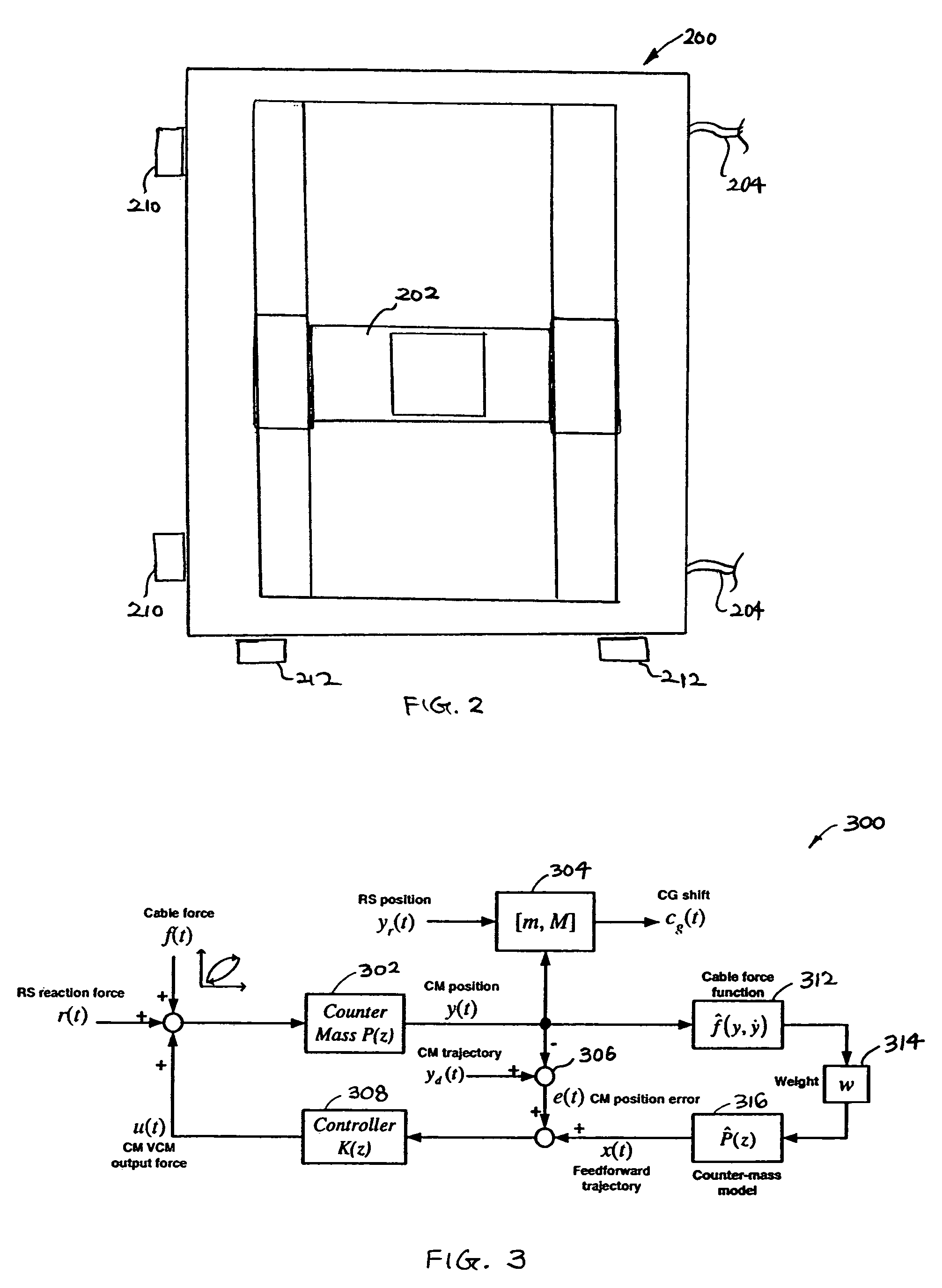

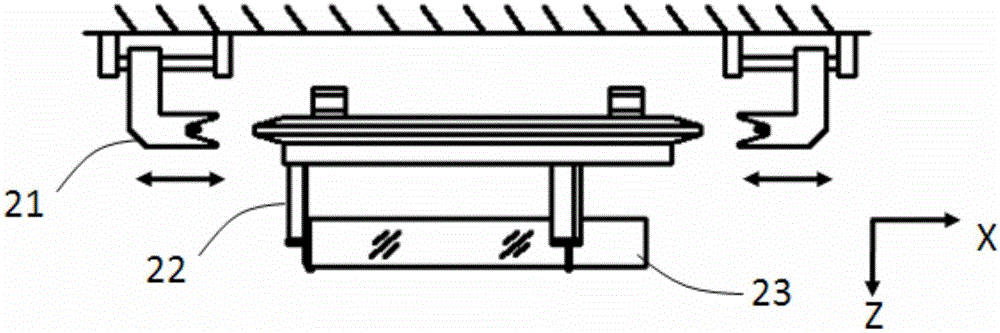

Minimum force output control method for counter-mass with cable

ActiveUS7366642B2Reduce and eliminate vibrationAmplifier modifications to reduce noise influenceForce measurementElectric machineEngineering

Owner:NIKON CORP

A positioning device for workpiece fixture in ion beam polishing equipment

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Rotor for turbomachines with shrouded blades

ActiveUS9004870B2Reduce and eliminate vibrationPropellersPump componentsEngineeringMechanical engineering

A rotor for turbomachines with shrouded blades comprising a row of a plurality of blades covered by an external ring, coaxial to said row of blades; the external ring being composed of a plurality of sectors, commonly referred to as shrouds, which are adjacent to one another and transversely and circumferentially attached to the end of respective blades; a damping member being arranged so as to straddle a respective pair of adjacent sectors and being pushed, in use, against radially internal surfaces of the sectors of the pair of adjacent sectors.

Owner:GE AVIO

Potter-bucky grid with counter-weight

InactiveUS7116758B2Reduces or eliminates the vibrations created by the moving gridReduce and eliminate vibrationHandling using diaphragms/collimetersReciprocating motionImage recording

A Potter-Bucky device for a radiation image recording apparatus in which an image recording medium is exposed to radiation which has passed through an object in order to record a radiation image of the object on the recording medium includes a grid which is movably supported between the object and the recording medium and is reciprocated parallel to the recording medium. A counter-weight is connected to the grid and is reciprocated in synchronization with the grid but in an opposite direction. Among other benefits and features, the disclosure reduces or eliminates vibrations produced by the reciprocating grid.

Owner:ANLOGIC CORP (US)

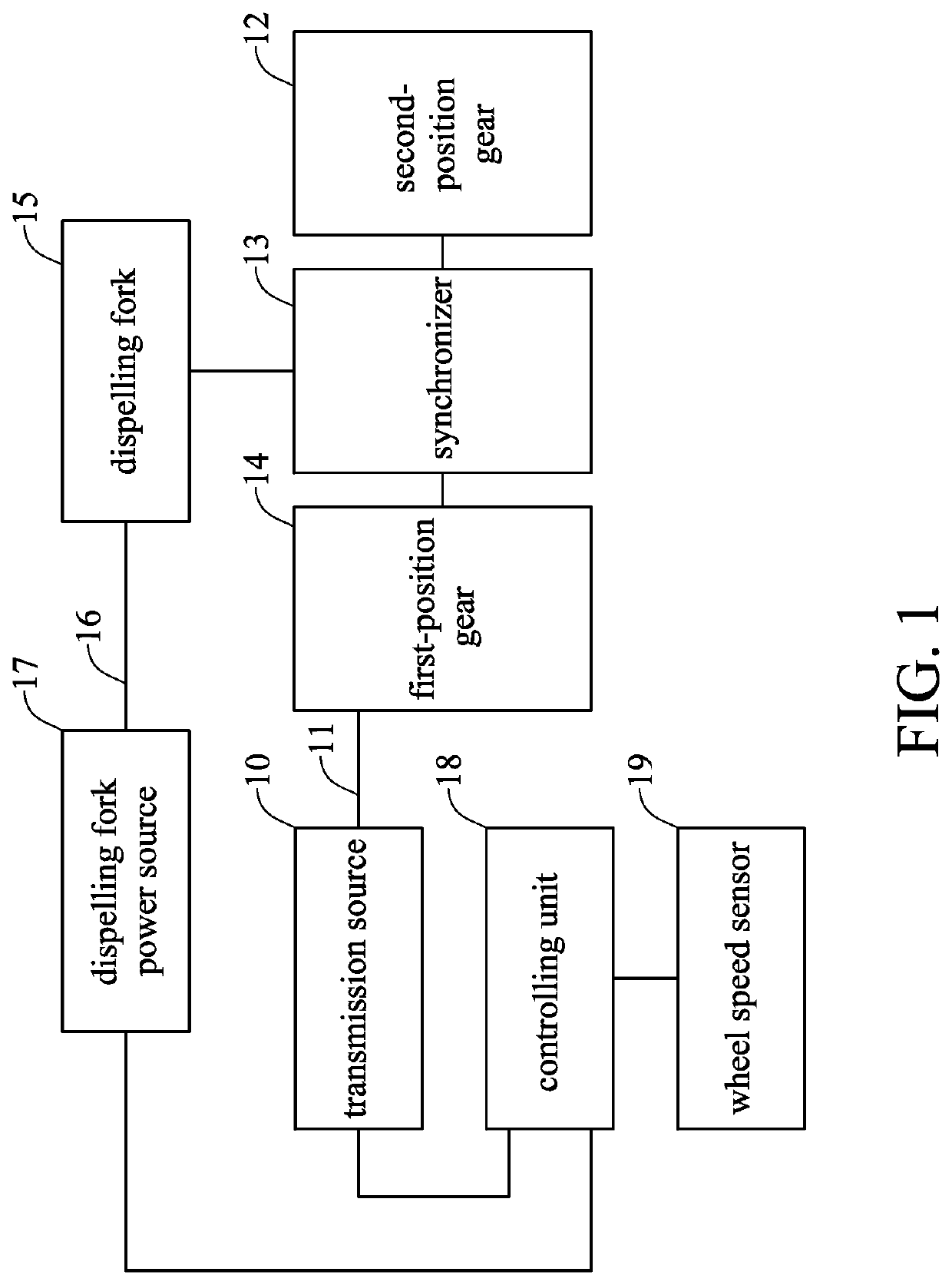

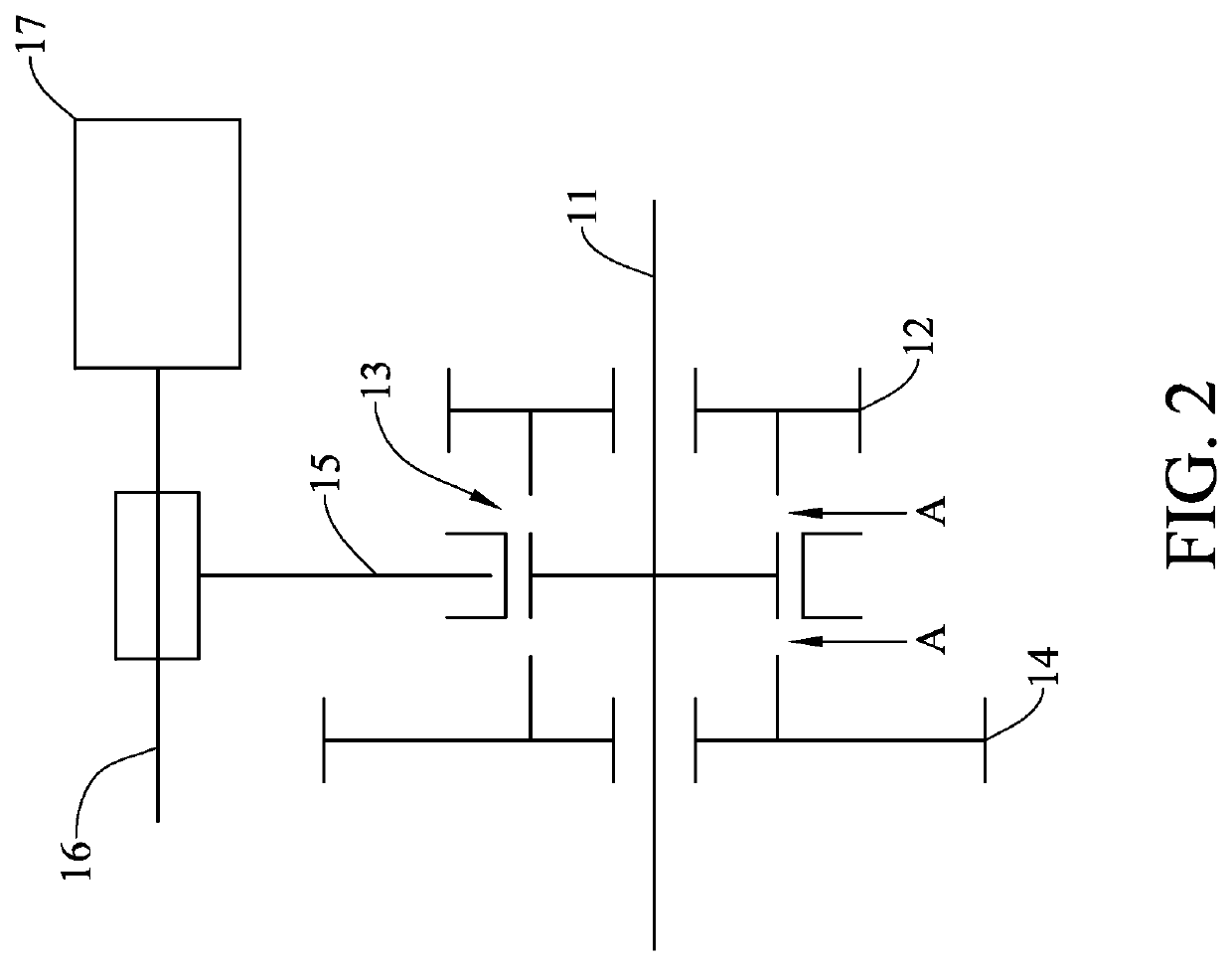

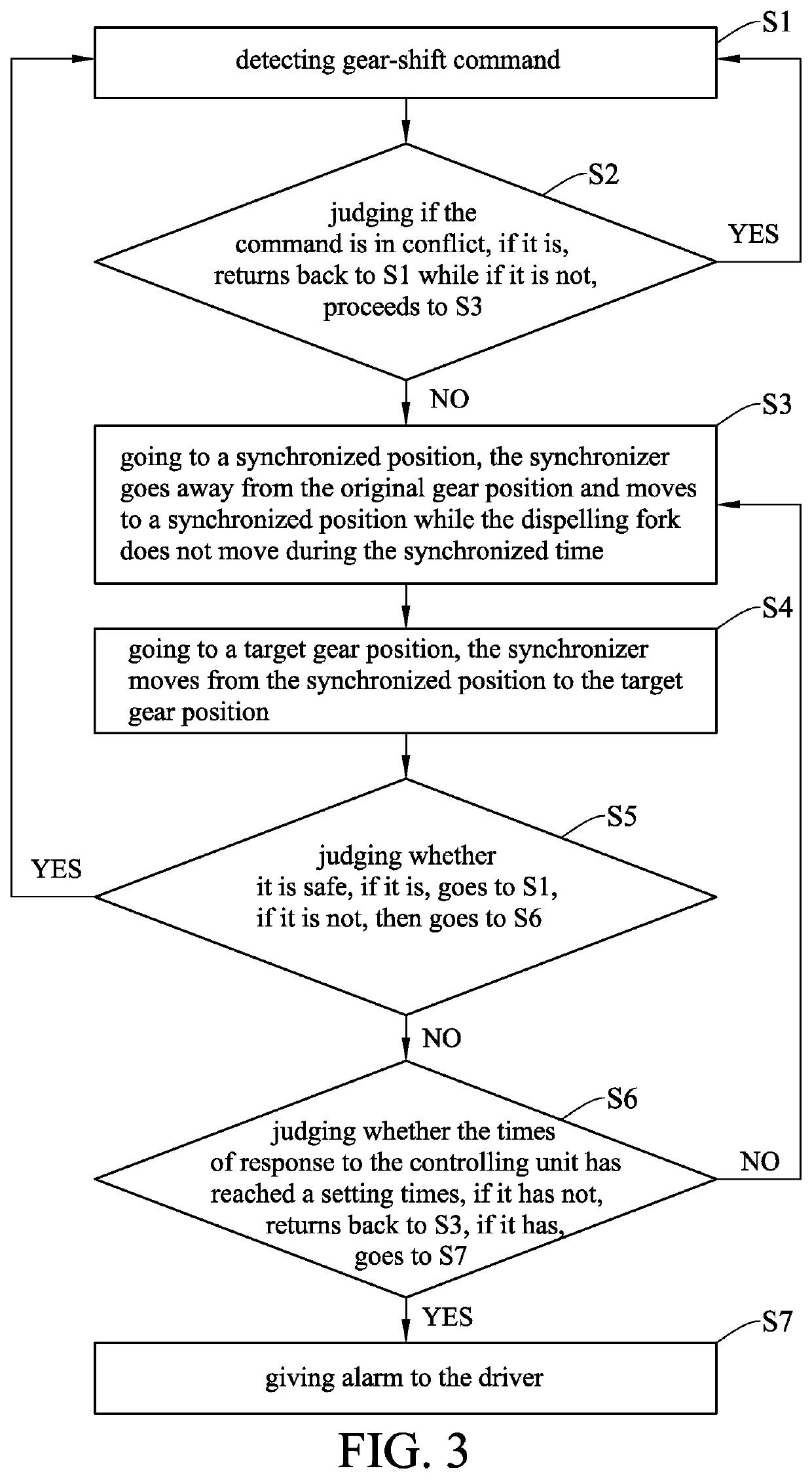

Electric vehicle transmission apparatus and method for making the same

InactiveUS20200132132A1Reduce and eliminate vibrationImprove performanceToothed gearingsGearing controlElectric vehicleElectric cars

An electric vehicle transmission method includes the steps of: detecting a gear-shift command; judging if the gear-shift command is in conflict, if it is in conflict, then it returns back to the step of detecting the gear-shift command while if it is not in conflict, then proceeds to the next step; proceeding to a synchronized position, a dispelling fork drives a synchronizer to make the synchronizer move from the original gear position to a synchronized position, and the dispelling fork does not move within a synchronized time; and proceeding to a target position, the dispelling fork drives the synchronizer again to make the synchronizer move to the target gear position.

Owner:IND TECH RES INST

Method for improved semiconductor processing equipment tool pedestal/pad vibration isolation and reduction

A method to improve vibration isolation in semiconductor process level inhibits vibration frequencies transmitted though building structure from production tools, pumps, compressors, chillers, AHUs (Air Handling Units), and footfalls traffic on raised floor system on to tool pedestals and pads from affecting semiconductor fabrication processes. The tool pedestal / pad for modern semiconductor FABs are required have very small tolerance to ambient vibration. Therefore, reduction and isolation of vibration of tool pedestal / pad is the key requirement for safe, reliable and uninterrupted operation of modern semiconductor FABs. Sound proofing material and foam is injected into hollow steel and / or aluminum support members and sound proofing adhesives and / or caulking are applied at points of connections in conjunction with mechanical fastening. In various applications, placement of shaped wielded rod utilized for dissipating vibration energy in center of hollow member which is surrounded with sound proofing material and / or foam.

Owner:SK COMML CONSTR INC

Crankshaft isolating pulley

ActiveUS9546709B2Reduce noiseReduce vibrationRotating vibration suppressionYielding couplingEngineeringCrankshaft

An isolating pulley comprising a hub comprising an inertia carrier, the inertia carrier having an inner surface, a spring carrier journalled to the hub, the spring carrier having a releasable driving engagement with the inertia carrier, a pulley journalled to the hub, a spring drivingly engaged between the spring carrier and the pulley, a clutch spring having a frictional engagement with the inner surface, and which frictional engagement is partially releasable upon a temporary, pressing contact of the pulley upon the clutch spring.

Owner:THE GATES CORP

Vibration damping connector and use of the vibration damping connector

InactiveUS10379372B2Reduce and eliminate vibrationQuality improvementVibration dampersSpringsEngineeringOptic system

The present invention refers to a vibration damping connector (100) for reducing vibrations between a vibration prone system and an optical imaging system, said vibration damping connector comprisinga first part (1) adapted to be connected to said optical imaging system,a second part (2) adapted to be connected to said vibration prone system, andat least one first shock absorbing element (3), a portion of said first part (1) is arranged inside a portion of said second part (2) along a central axis (A) or a portion of said second part (2) is arranged inside a portion of said first part (1) along a central axis (A) and said at least one flexible shock absorbing element (3) is arranged between said first part (1) and said second part (2), said vibration damping connector (100) further comprisesat least one fastening device (4) for fastening said first part (1) to said second part (2) and said fastening device (2) presses said first part(1) to said second part (2) via a second shock absorbing element (5). Furthermore, use of the vibration damping connector, in an optical system is disclosed.

Owner:INL INT IBERIAN NANOTECHNOLOGY LAB

Systems and methods for reducing detected intensity non uniformity in a laser beam

InactiveUS20080309926A1Evenly spacedReduce lightPhotometryOptical elementsLight beamUltimate tensile strength

A method of increasing the spatial uniformity of the detected intensity of a beam of light from a laser in a system including the laser and a light detector. In one embodiment the method includes the steps of generating a beam of light with the laser; and moving the beam of light and the light detector relative to each other, such that the detector averages the spatial intensity of the beam of light over time. In another embodiment the invention relates to a system for increasing the detected spatial uniformity of the intensity of a beam of light. In one embodiment the system comprises a light detector; a laser source for generating the beam of light; and a means for moving the beam of light and the detector relative to one another such that the detector averages the intensity of the light beam over time.

Owner:FLUIDIGM CORP

Cord material and methods of using same

ActiveUS9447529B2Improved drag performance characteristicReduce and eliminate vibrationBraidTextile cablesEngineeringAerodynamics

A cord material suitable for use in lined textile structures with a gliding component includes a plurality of uniform strands, and a deviant strand. The deviant strand is different from the uniform strands in some characteristic affecting aerodynamic or hydrodynamic properties of the cord, such as size or surface properties. Each uniform strand can have a substantially equal cross section area, while the deviant strand has a cross section area at least five times greater than one of the uniform strands. The strands can be braided or woven together. A major benefit of the material can be that vibration induced drag is significantly reduced or eliminated in lines made with the material. Another advantage is that lines made from the material can have more consistent, predictable line drag, which can improve the quality of handling.

Owner:A Z CHUTEWORKS L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com