Ultrasonic emulsion breaking oil-gas-water separator and separation method

An oil-gas-water separator technology, applied in the field of oil exploitation, can solve the problems of not using upper oil enrichment and lower water enrichment, destroying oil-water-gas separation, weak demulsification function, etc., to ensure long-term stable operation effect and on-site adaptation. The effect of strong performance and elimination of the effect of system scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

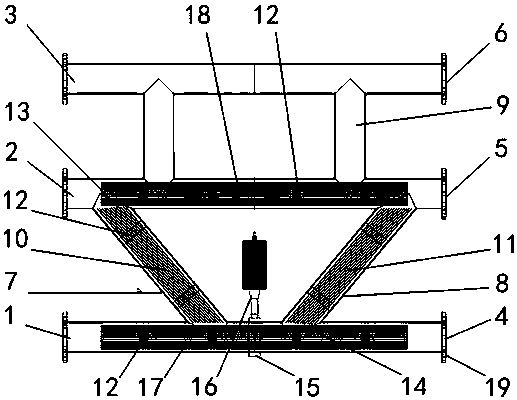

[0035] Such as figure 1 and Figure 5 Shown, the present invention has multiple in actual operation figure 1 The shown oil-water-gas separation module consists of Figure 5For the oil-water-gas separation unit shown, the specific number of components is mainly determined by the characteristics of the incoming crude oil on site, and the equipment of other oil-water separation equipment on site is also considered. In short, the more oil-water-gas separation modules in the oil-water-gas separation unit, the more The better the separation.

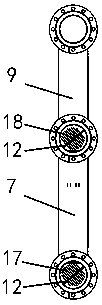

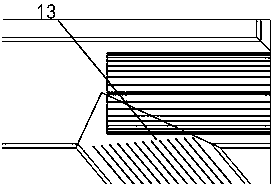

[0036] Such as Figure 1-3 As shown, the present invention discloses an ultrasonic demulsification oil-gas-water separator, comprising a liquid inlet pipe 1, an oil phase pipe 2, a gas phase pipe 3 parallel to each other, a slant plate support rod 12 and an ultrasonic vibration transmission ring 15. The liquid pipe 1 is connected to the oil phase pipe 2 arranged above it at an angle of 40° to 50° through the first inclined standpipe 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com