Four-way reversing valve for heat pump air conditioner

A four-way reversing valve, heat pump air-conditioning technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of unfavorable system piping assembly and insertion, large heat loss, etc., to reduce heat loss, improve production efficiency, The effect of improving the welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

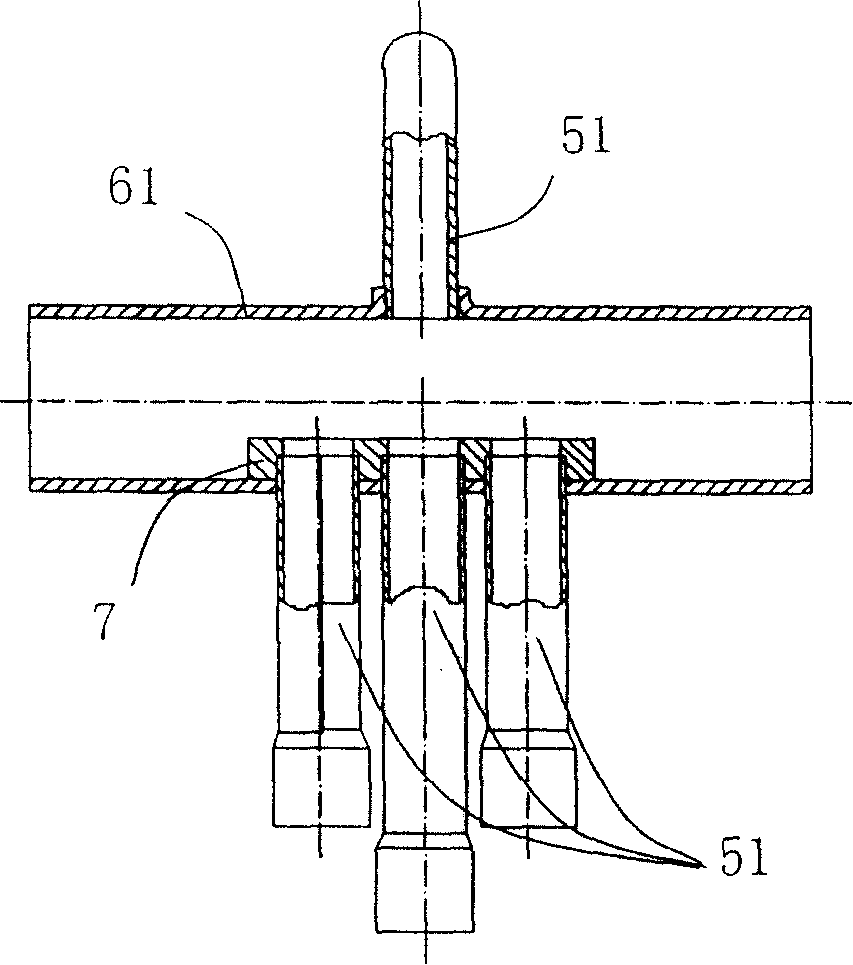

[0024] Embodiments of the present invention will be specifically described below in conjunction with accompanying drawings 5 to 7 .

[0025] Firstly, process the main valve body 62 , the end cap 8 , and four connecting pipes 52 D, C, E, and S; wherein, the main valve body 62 and the end cap 8 are made of stainless steel. Four through holes 62a are arranged on the main valve body 62; E, S, D, and C take over are red copper and stainless steel composite pipes, the inner layer 52a of which is red copper, and the outer layer 52b is stainless steel. The end of the connecting pipe 52 is flanged outwards into an arc-shaped flanging 52c so that the adhering surface 52d of the flanging coincides with the outer surface of the main valve body 62 .

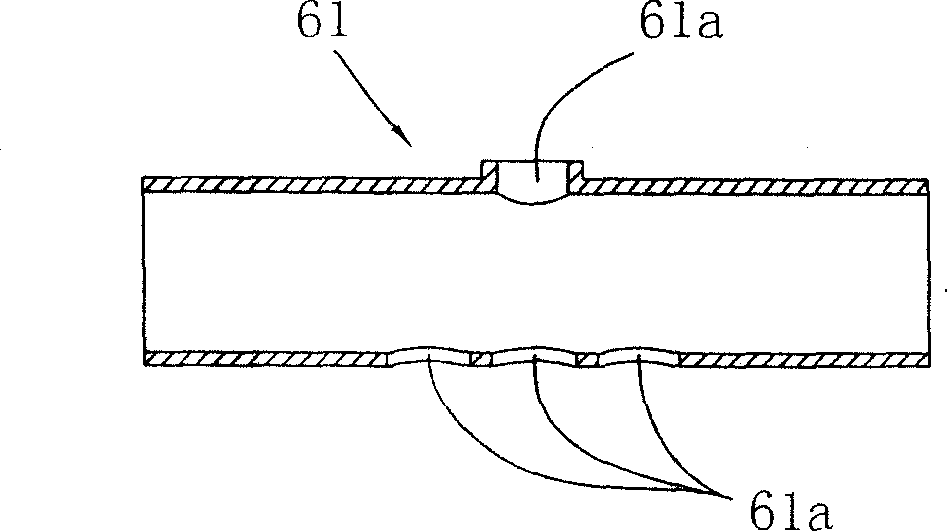

[0026] The valve seat 7 is fixed on the inner surface of the main valve body 62 by spot welding or clamps, the arc surface of the valve seat 7 is attached to the inner surface of the main valve body 62, and the valve seat hole 62a communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com