Corrosion-resistant metal membrane assembly and laser welding method thereof

A metal thin film and laser welding technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of low production efficiency, expensive equipment, and affecting the time of welding cycle, so as to reduce manufacturing difficulty and cost, The effect of reducing equipment investment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

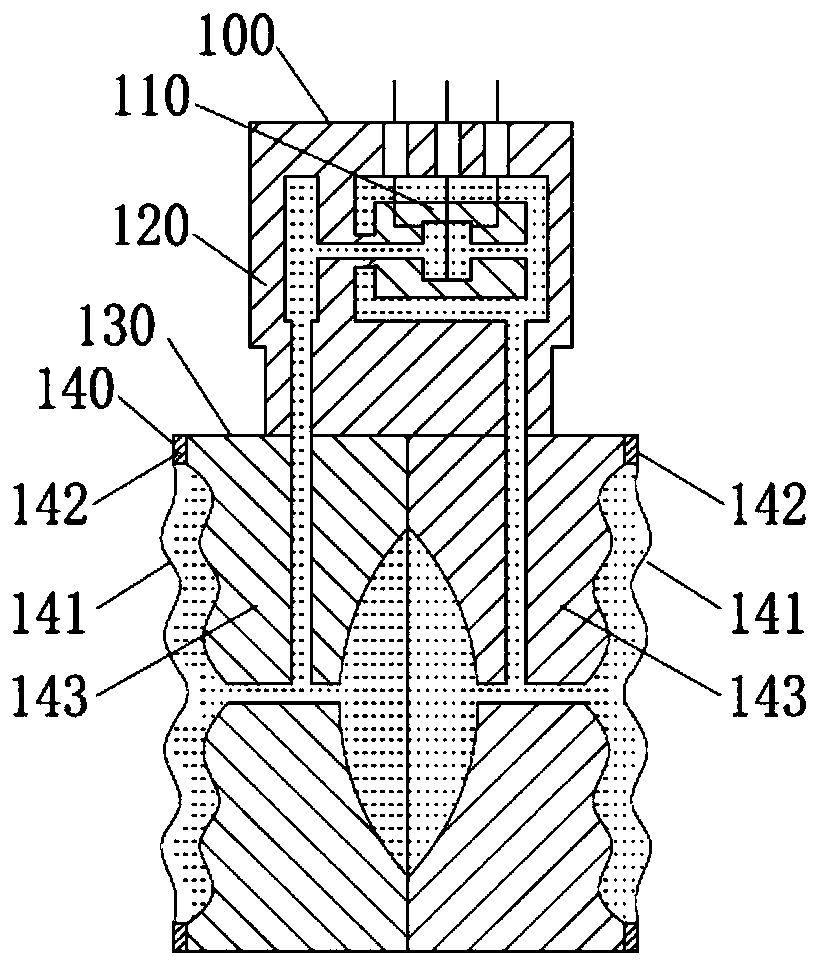

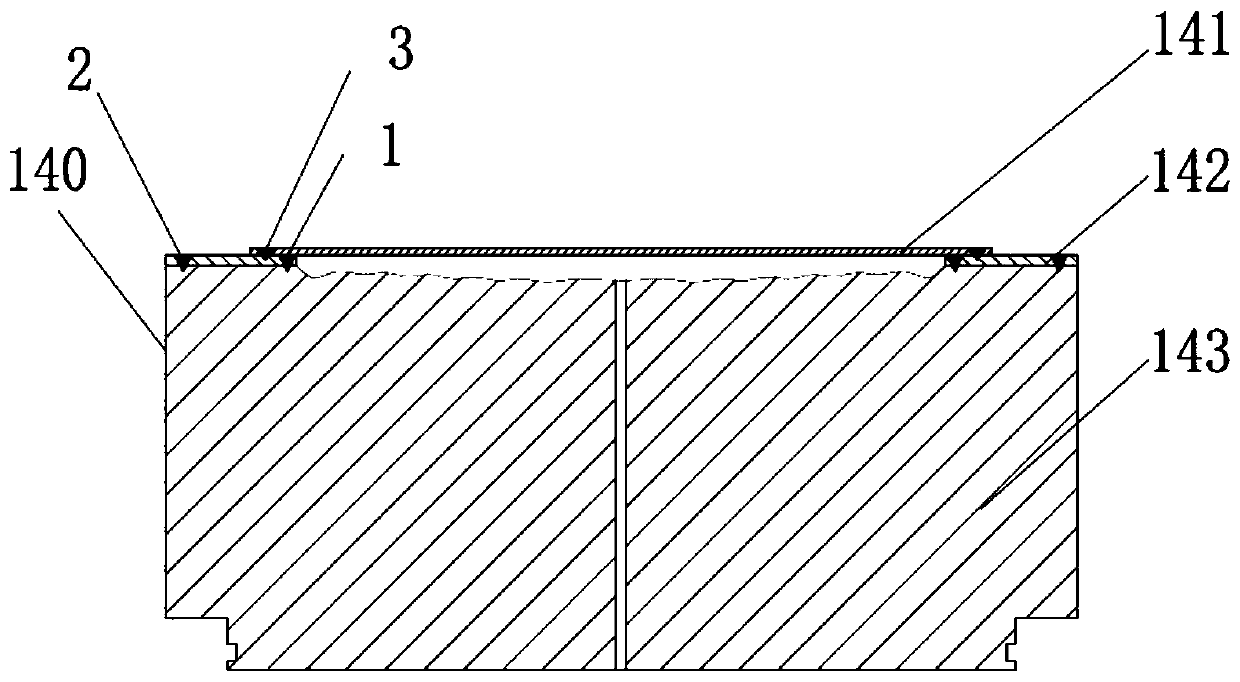

[0040] Such as Figure 1-Figure 2 As shown, the present invention includes the existing pressure transmitter detection part used in the measurement, the pressure transmitter detection part 100 is mainly composed of a sensor part 110, a cup body part 120, and a bellows part 130 welded to form an integrated structure . The bellows part 130 is composed of a bilaterally symmetrical isolation diaphragm part 140 .

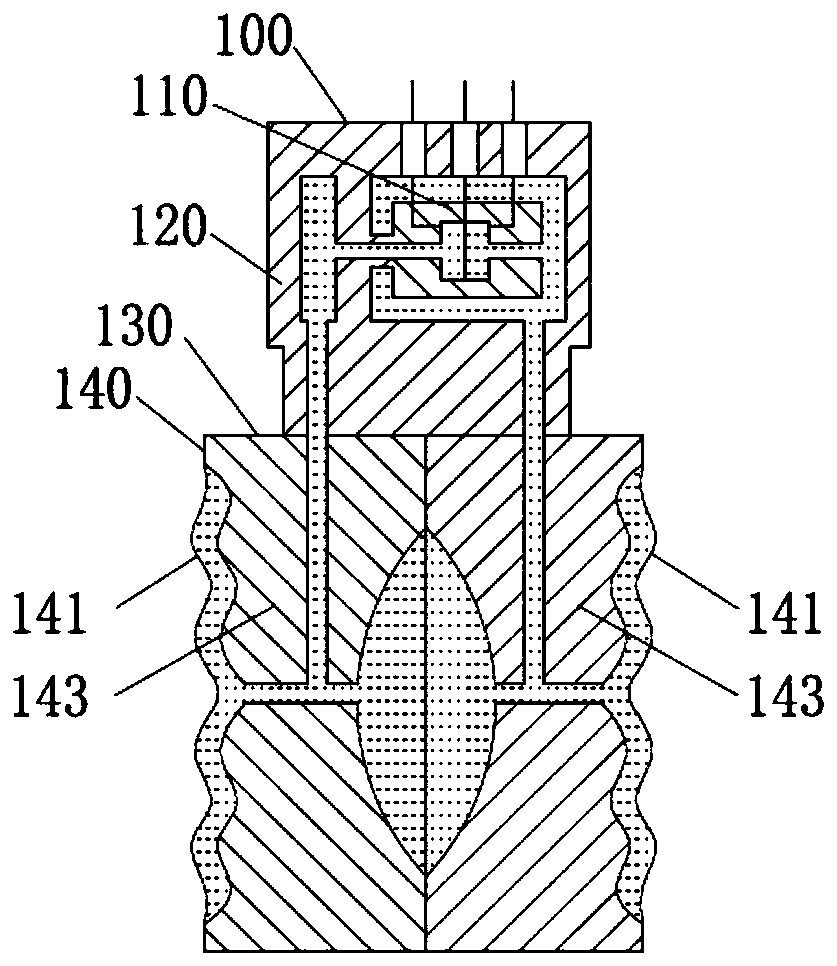

[0041] Such as figure 1 As shown, the corrosion-resistant material isolation diaphragm 141 designed in the present invention, the corrosion-resistant material gasket 142 and the body 143 are welded into one special structure, instead of figure 2 The anti-corrosion material isolation diaphragm 141 and the anti-corrosion material body 143 are combined by welding.

[0042] The present invention now takes tantalum metal material as an example, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com