Full-automatic root welding method for pipe end of bimetal composite pipe

A bimetallic composite pipe, fully automatic technology, applied in the direction of metal processing equipment, welding equipment, welding medium, etc., can solve the problems of difficult control of manual welding process, irregular appearance surface, easy to be burned by arc, etc., to improve labor efficiency Production efficiency, convenient construction, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

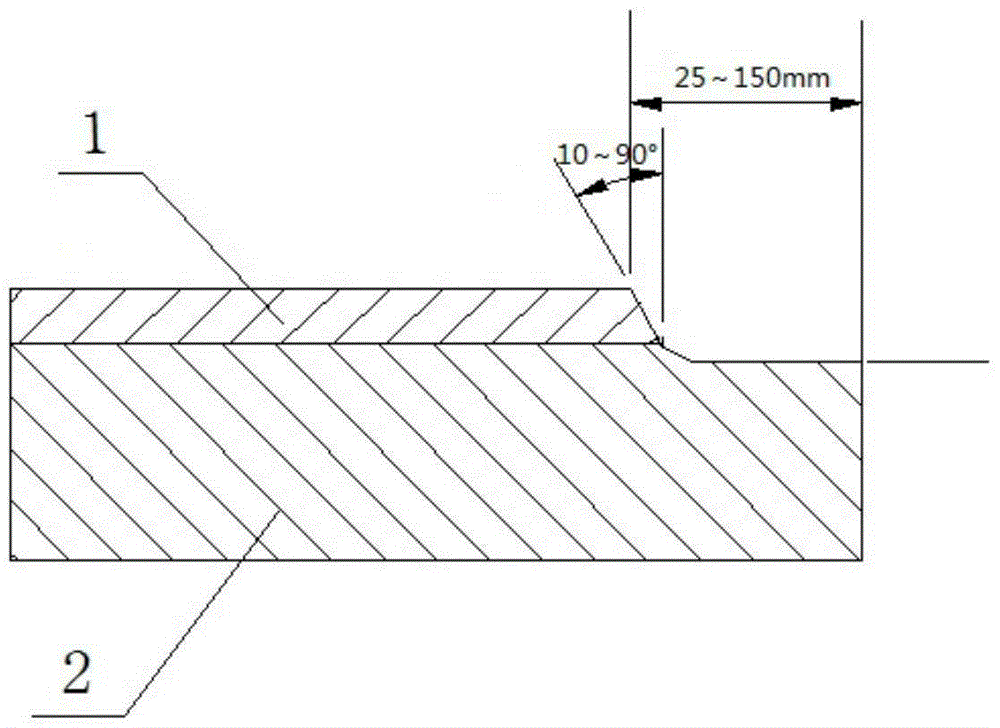

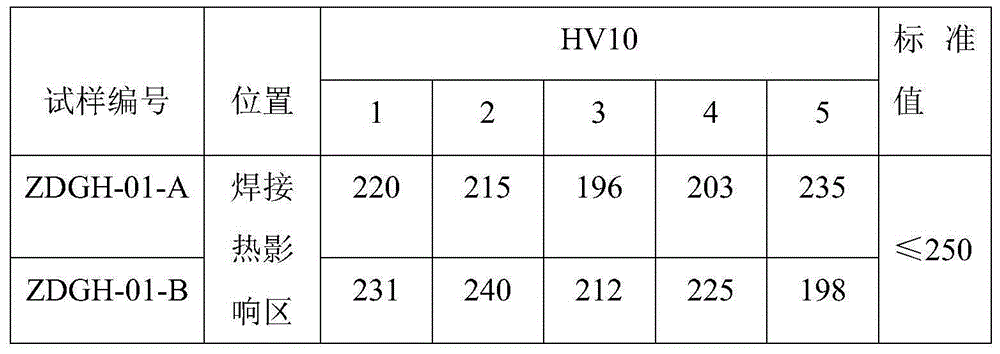

[0036] The bimetallic composite pipe to be welded is a composite pipe composed of a nickel-based alloy lining pipe 1 made of 825 nickel-based alloy and a carbon steel base pipe 2 made of L415QS carbon steel, and its specification is medium 217.8x (8+2.5)mm.

[0037] Step 1, first cut off the corrosion-resistant alloy liner 1 to a length of 25mm, and then process the outside of the exposed corrosion-resistant alloy liner 1 from outside to inside to form an inwardly inclined slope; the slope angle of the slope is 60°;

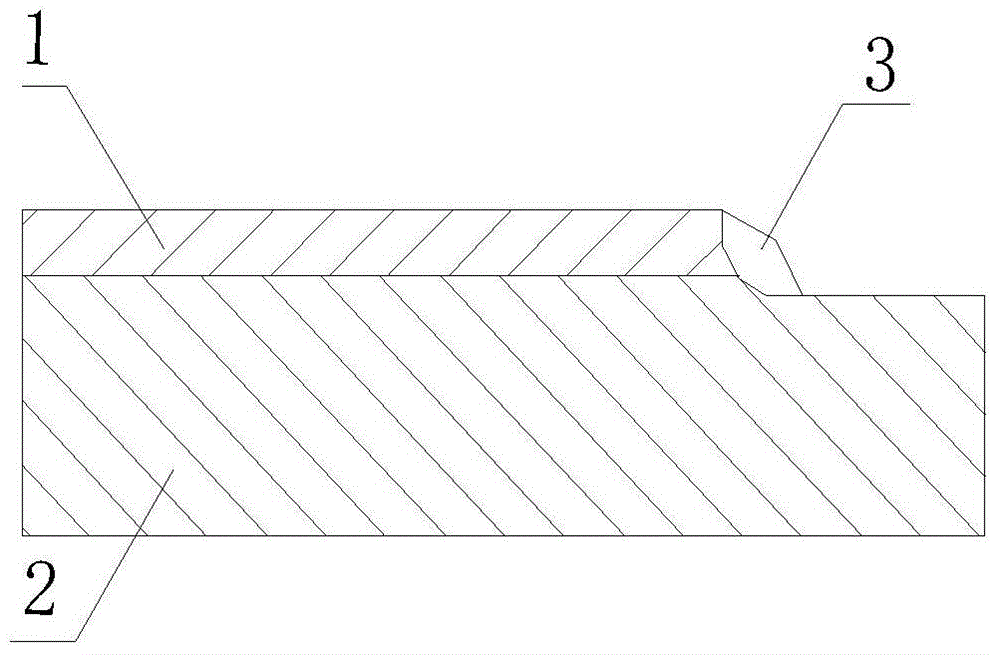

[0038] Step 2, under the protection of argon, use a fully automatic hot wire TIG welding machine to root weld from inside to outside on the inclined surface and form a single layer of nickel-based alloy root welding layer 3, the height of the inner wall of the nickel-based alloy root welding layer 3 is not low The height of the inner surface of the corrosion-resistant alloy lined pipe 1. The welding materials used are nickel-based alloy welding wire ERNiCrMo-3 / Φ...

Embodiment 2

[0040] The bimetallic composite pipe to be welded is a composite pipe composed of stainless steel lining pipe 1 made of 316L stainless steel and carbon steel base pipe 2 made of L360QS carbon steel, and its specification is medium 219.1x(10+2 )mm.

[0041] Step 1, first cut off the length of 60mm of the stainless steel lining pipe 1, and then process the outside of the exposed stainless steel lining pipe 1 from outside to inside to form an inwardly inclined slope; the slope angle of the slope is 75°;

[0042]Step 2, under the protection of argon, use a fully automatic hot wire TIG welding machine to root weld from inside to outside on the inclined surface and form a single layer of nickel-based alloy root welding layer 3, the height of the inner wall of the nickel-based alloy root welding layer 3 is not low The height of the inner surface of the stainless steel lined pipe 1. The welding materials used are nickel-based alloy welding wire ERNiCrMo-3 / Φ0.9; corrosion-resistant al...

Embodiment 3

[0044] The bimetal composite pipe to be welded is a composite pipe composed of a stainless steel lining pipe 1 made of 316L stainless steel and a carbon steel base pipe 2 made of L245N carbon steel, and its specification is medium 219.1x(11.1+3 ) mm.

[0045] Step 1, first cut off the corrosion-resistant alloy liner 1 to a length of 90 mm, and then process the outside of the exposed corrosion-resistant alloy liner 1 from outside to inside to form an inwardly inclined slope; the slope angle of the slope is 45°;

[0046] Step 2, under the protection of argon, use a fully automatic hot wire TIG welding machine to root weld from inside to outside on the inclined surface and form a single layer of nickel-based alloy root welding layer 3, the height of the inner wall of the nickel-based alloy root welding layer 3 is not low The height of the inner surface of the stainless steel lined pipe 1. The welding materials used are nickel-based alloy welding wire ERNiCrMo-3 / Φ0.9; corrosion-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com