Thermocouple welding clamping device

A technology of thermocouples and welding clamps, applied in welding equipment, auxiliary devices, welding accessories, etc., can solve the problems of safety risks such as electric shock, large human influence factors, high pass rate, etc., to reduce human influence factors and simple structure , The effect of high welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

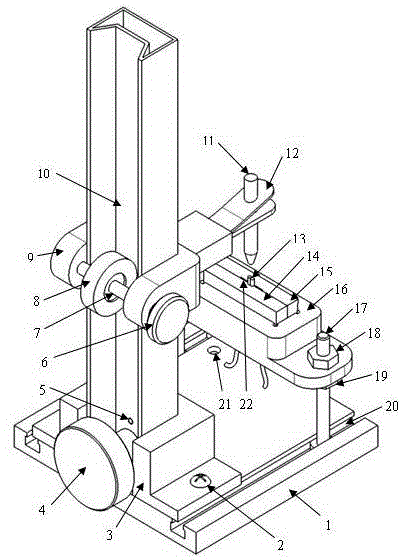

[0011] like figure 1 As shown, the clamping device for thermocouple arc welding disclosed by the present invention is composed of a supporting part, a clamping part and an adjusting part.

[0012] The supporting part includes a base 1 , a support 3 and a bracket 10 . The support 3 is connected to the base 1, preferably a polymer material with a certain strength, but not limited to the support formed by plastic material. The structural feature of the support 3 is that it has a T-shaped concave surface, which can ensure the verticality and stability of the bracket 10 . The support 10 is fixed on one end of the base 1 by two screws 2 through the support 3 , and the support 10 is fixedly connected with the support 3 through the fixing bolt 4 and the support positioning pin 5 . The support 10 has two parallel surfaces and a U-shaped cross-section. One of the surfaces is shaped with a scale. Its main function is to directly and accurately control the vertical position of the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com