Surface-mounted microwave circulator with novel port structure

A port structure, mount-type technology, applied in the field of surface mount microwave circulators, can solve the problem of not being able to weld the circulator shell and the circuit board, affecting the working performance of the debugged device, and dislocation of the circulator port pins, etc. Solve problems, achieve excellent performance, stable positioning, and improved welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

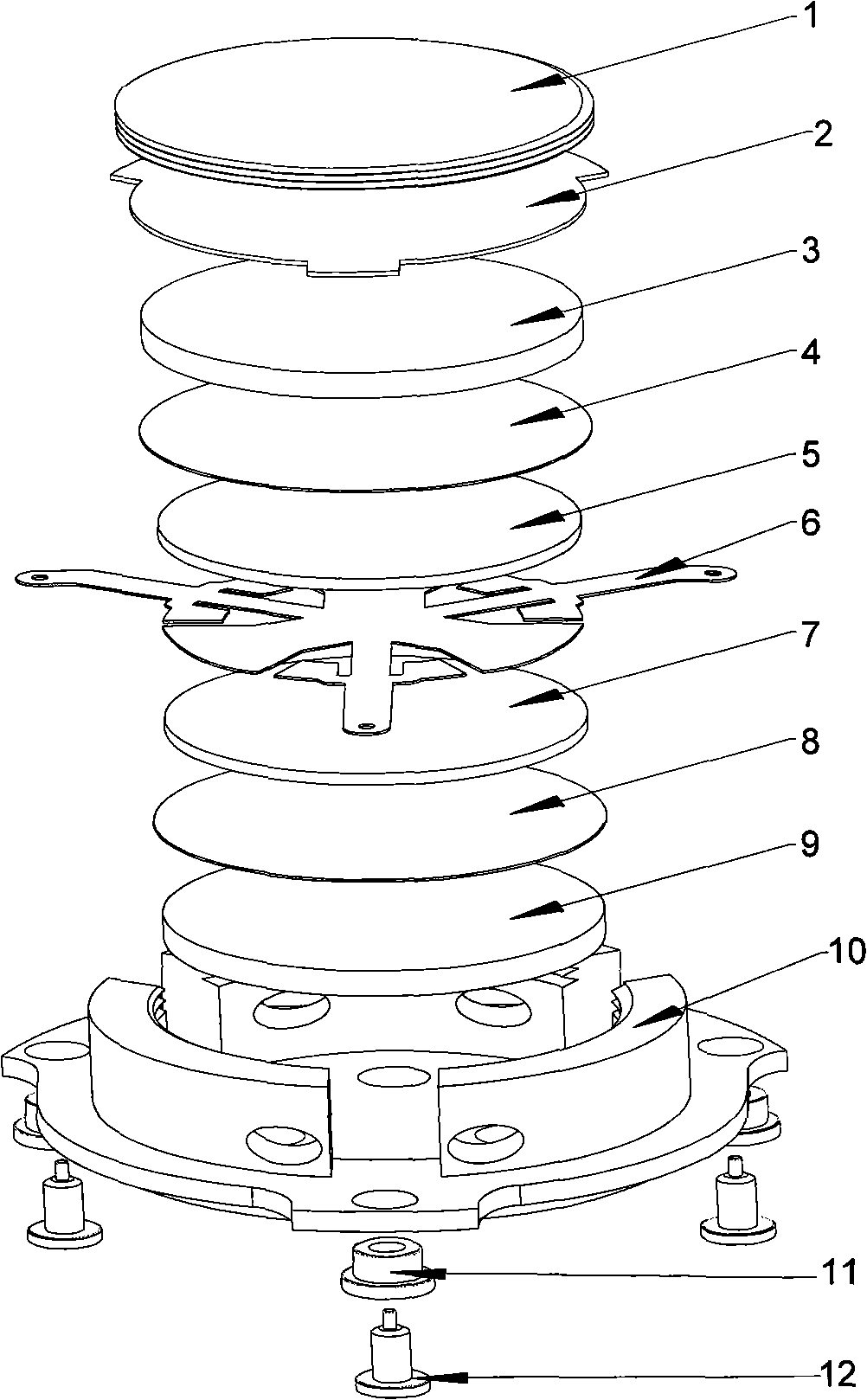

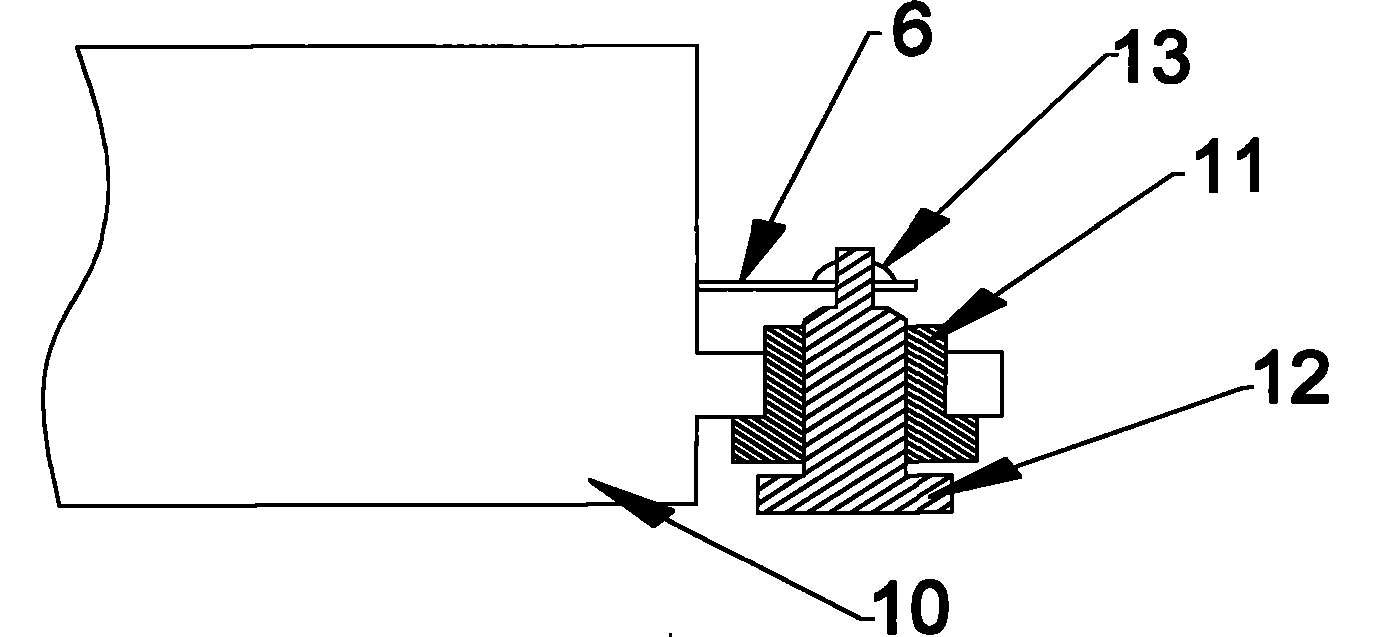

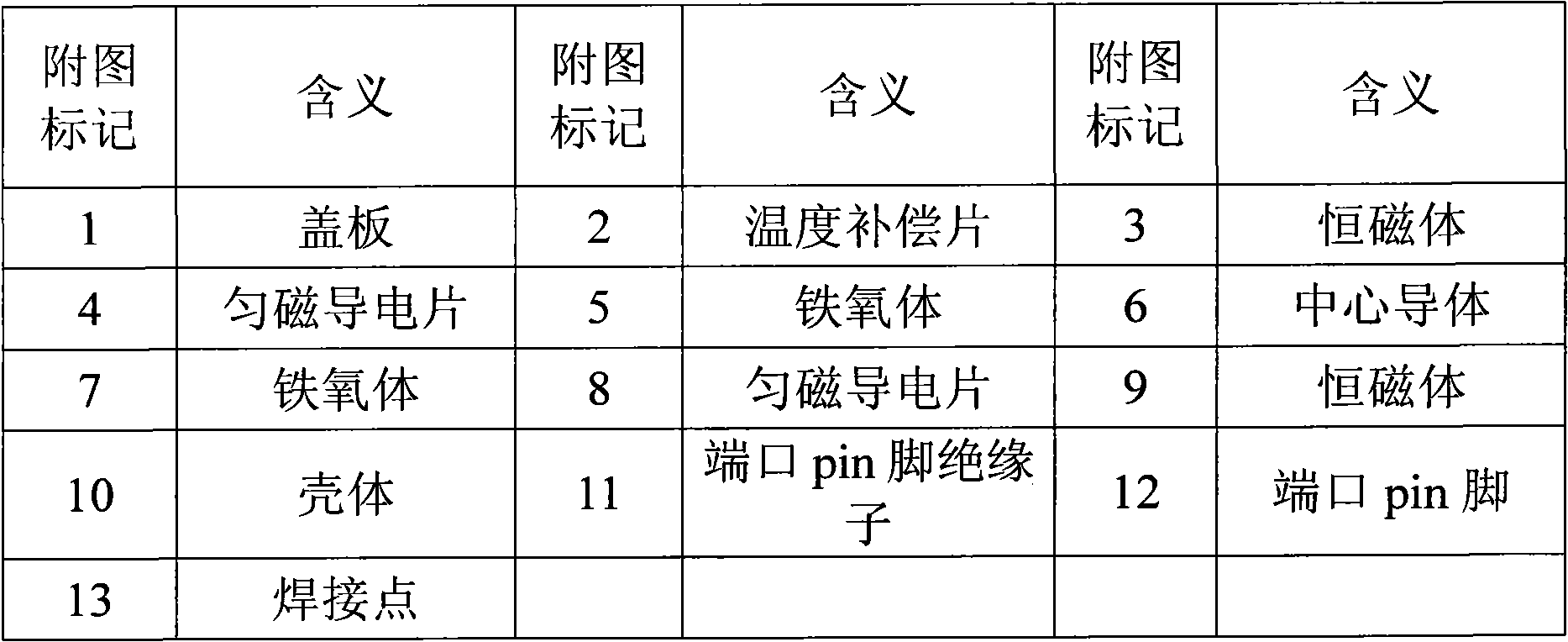

[0020] Such as figure 1 As shown, a surface-mounted microwave circulator with a new port structure includes a housing 10 and a cover plate. The housing 10 is a semi-open cylindrical cavity structure. The side wall of the housing 10 is provided with three port slots. Bosses are respectively provided on the side wall of the body corresponding to the positions of the three port slots, and a permanent magnet 9, a uniform magnetic conductive sheet 8, a ferrite 7, and a central conductor are sequentially placed in the semi-open cylindrical cavity of the shell. 6. Ferrite 5, uniform magnetic conductive sheet 4, permanent magnet 3 and temperature compensation sheet 2, the top of the housing 10 is covered with a cover plate 1, and the central conductor 6 protrudes out of the cavity through the port slot on the side wall of the housing ,Such as figure 1 As shown, the three bosses on the side wall of the shell are all provided with through holes, and each through hole is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com