Vibration friction welding jig of sliced plastic air intake manifold

A technology of intake manifold, vibration and friction, which is applied in household appliances, other household appliances, household components, etc. It can solve the problem of welding fixtures without adjustable product outline repositioning, welding fixture debugging time is long, and customers cannot be satisfied Requirements and other issues, to achieve the effect of high welding strength and reliability, short debugging time, and improve the welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

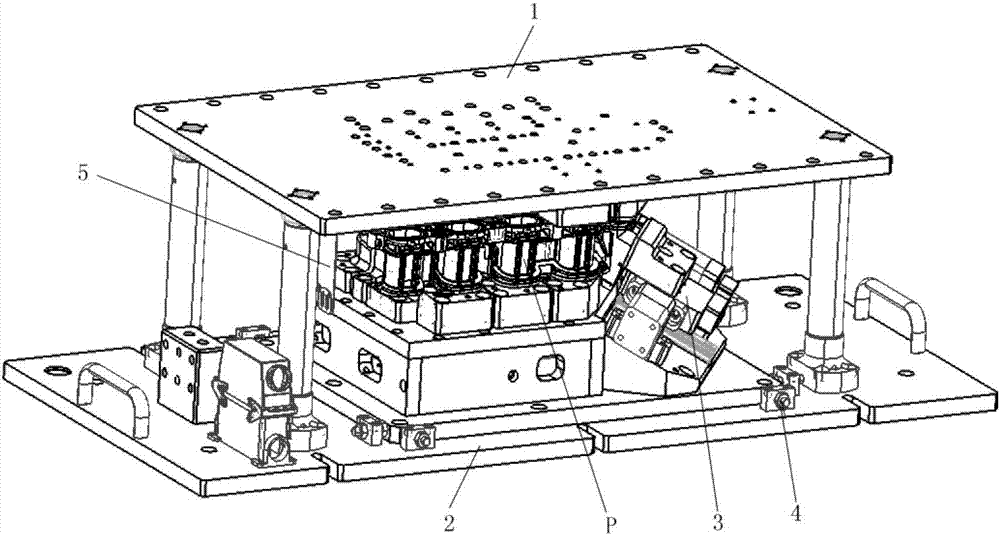

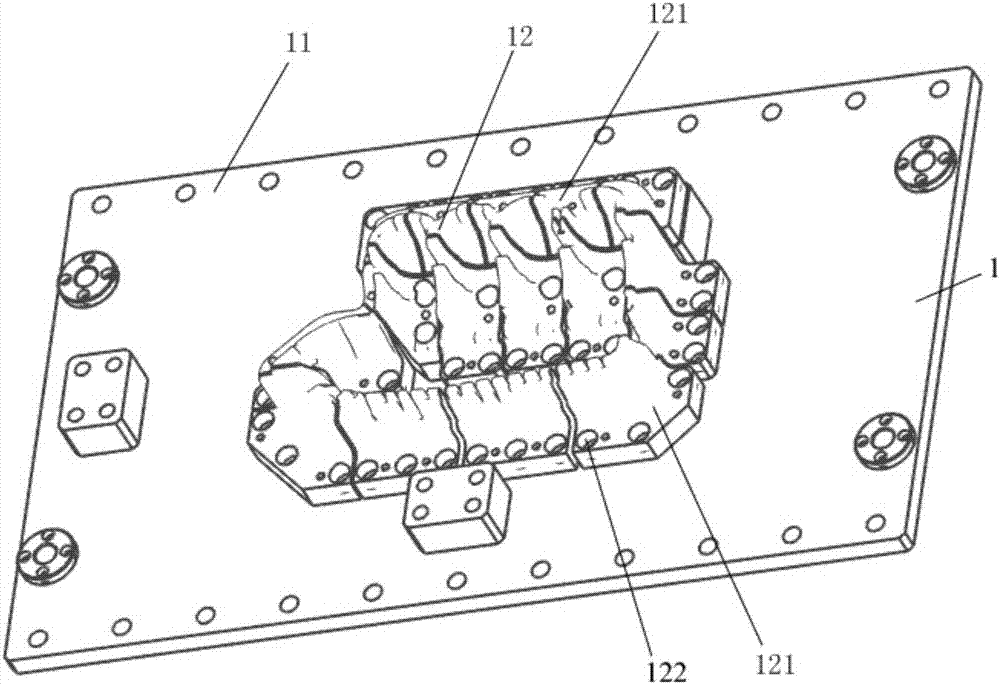

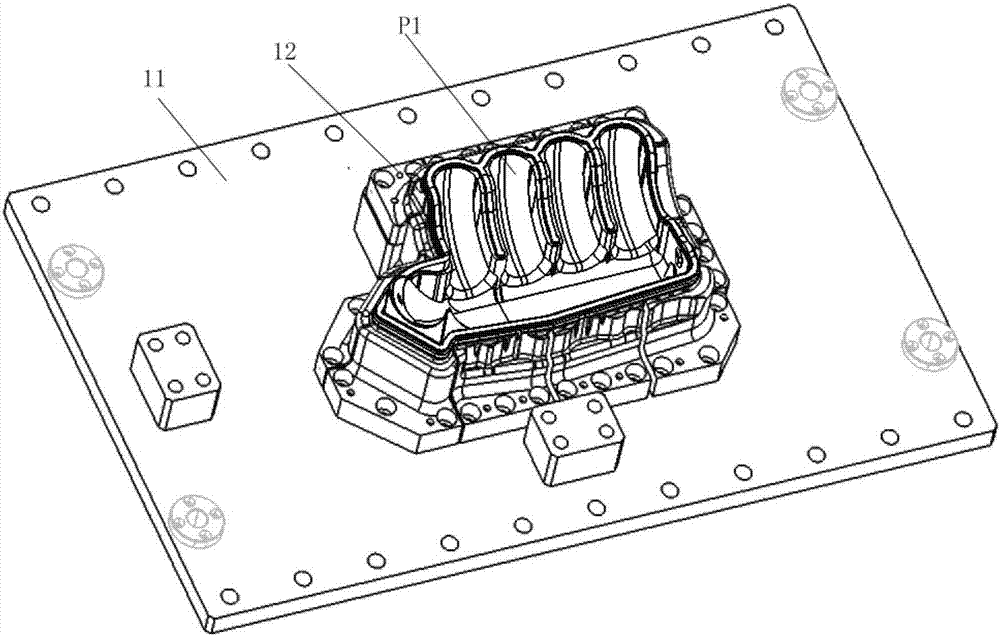

[0019] Embodiment 1: A vibratory friction welding fixture for a sliced plastic intake manifold, such as Figure 1-Figure 5 As shown, it includes an upper fixture 1 and a lower fixture 2. The upper fixture 1 includes an upper mounting plate 11 and an upper contour support positioning assembly 12 that matches the contour of the upper half of the intake manifold. The upper contour supports The positioning assembly has an upper profile support rib for supporting the welding ribs in the upper half of the intake manifold. The upper profile support positioning assembly is assembled from 16 small support positioning blocks I121, and each small support positioning block I has at least There are two screw mounting holes 122, and the small support positioning block I is mounted on the upper mounting plate 11 by screws. By adjusting the position of each small support positioning block I, the profile and size of the upper profile support positioning assembly can be fine-tuned.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com