Method for avoiding solder bridge

A technology of tin bridging and wave soldering, which is applied in the field of avoiding improper solder bridging between two adjacent soldering points, so as to improve the first-pass rate, reduce maintenance costs, and improve the soldering qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

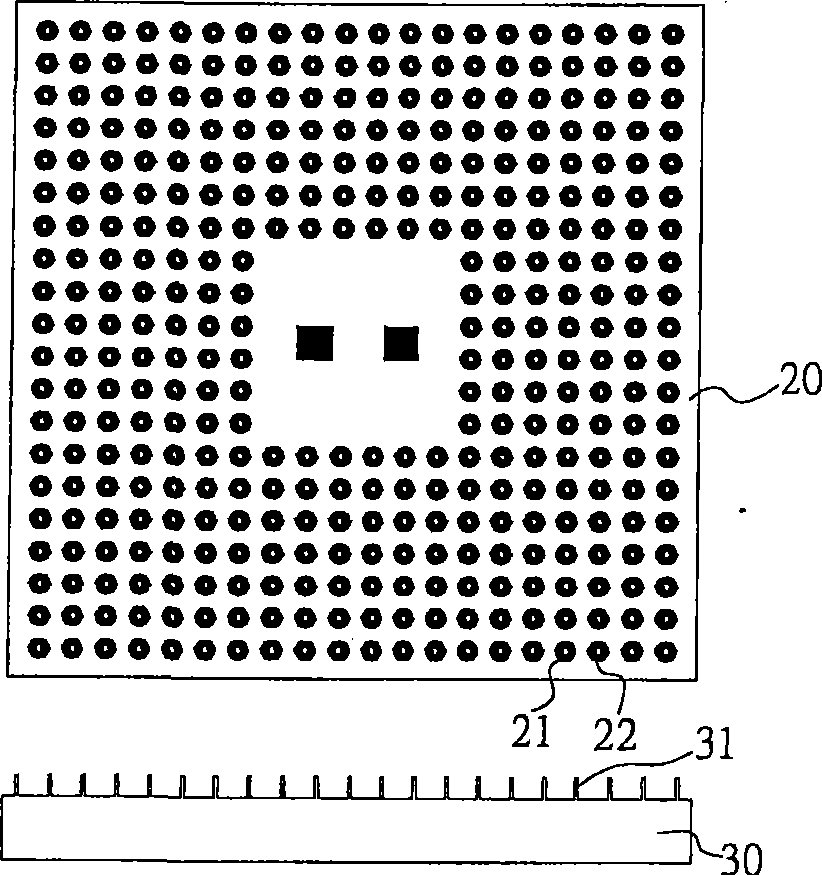

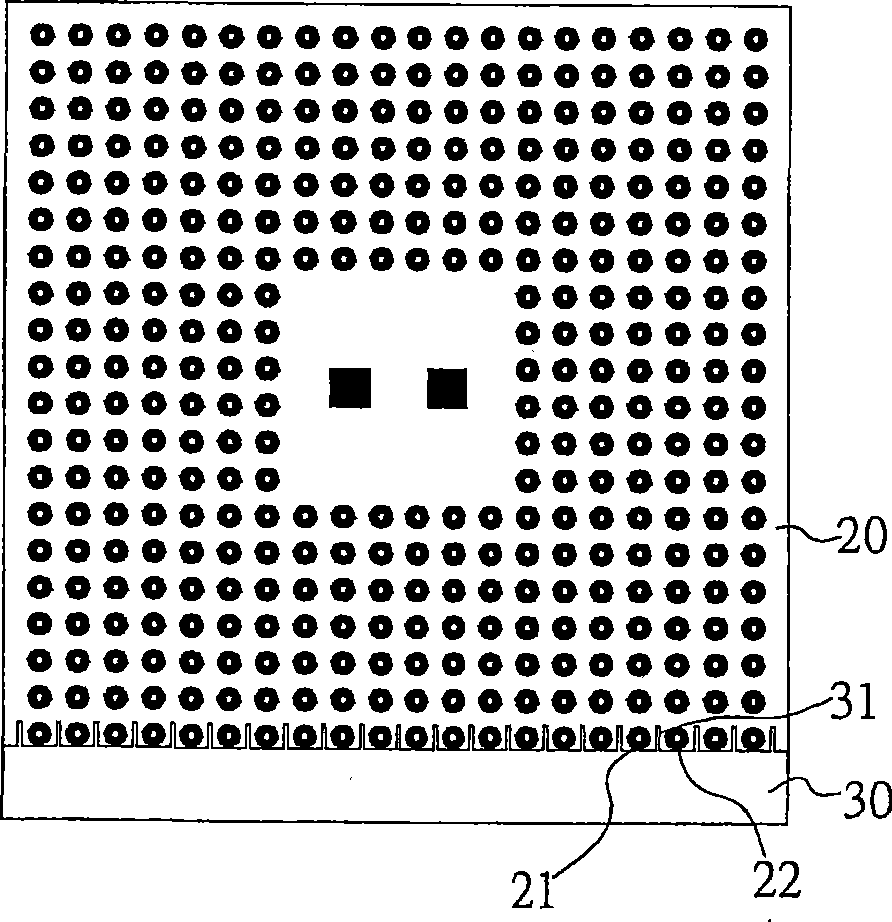

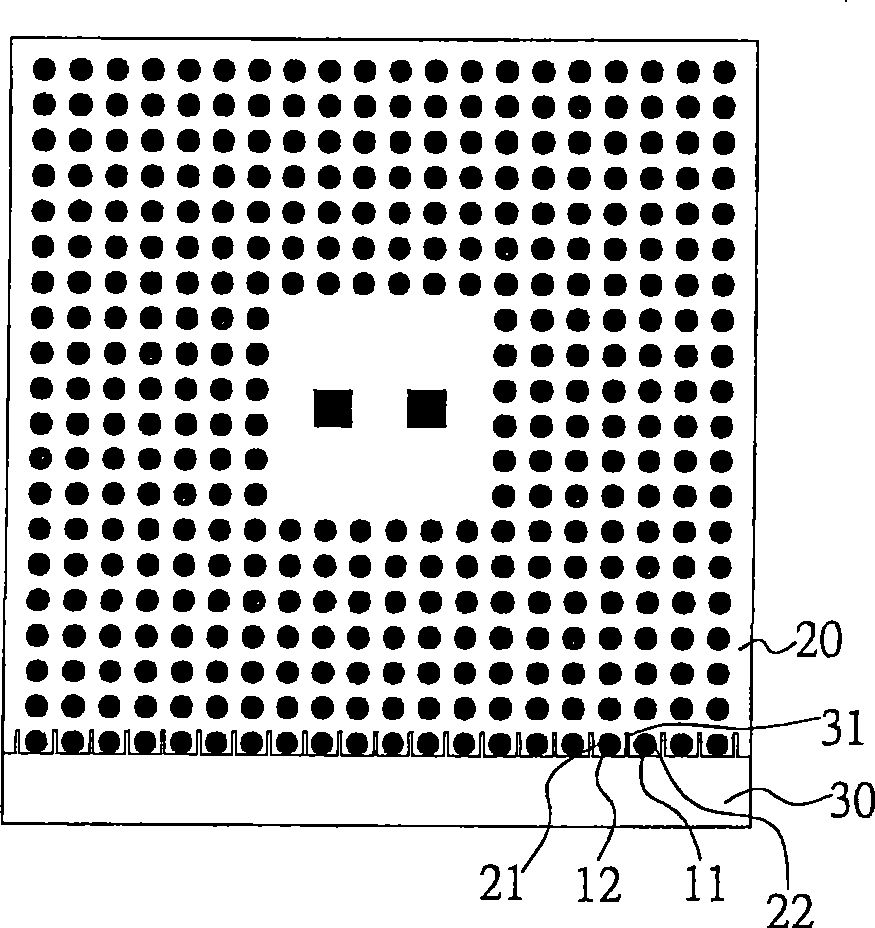

[0051] According to the welding theory, the smaller the distance between the parts holes, the easier it is to cause the phenomenon of tin connection (bridging). In order to prevent the phenomenon of tin connection (bridging) during soldering when the spacing between the parts feet is ≤ 2mm and the gap between the parts holes corresponding to the parts feet on the printed circuit board is ≤ 0.6mm, the present invention uses between two parts holes Solder mask material to be isolated. For example, a steel sheet with a thickness of 0.1-0.2mm is used to set up multiple dams or retaining walls with a width of 0.15-0.20mm, that is, isolation strips (lines), which can isolate and block the tin liquid during welding, effectively preventing two The phenomenon of tin connection (bridging) occurs in adjacent parts holes.

[0052] see figure 1 shown. In order to solve electronic products, such as the pin seat of the central processing unit in the wave soldering, the last row of part p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com