Production of conducting wire

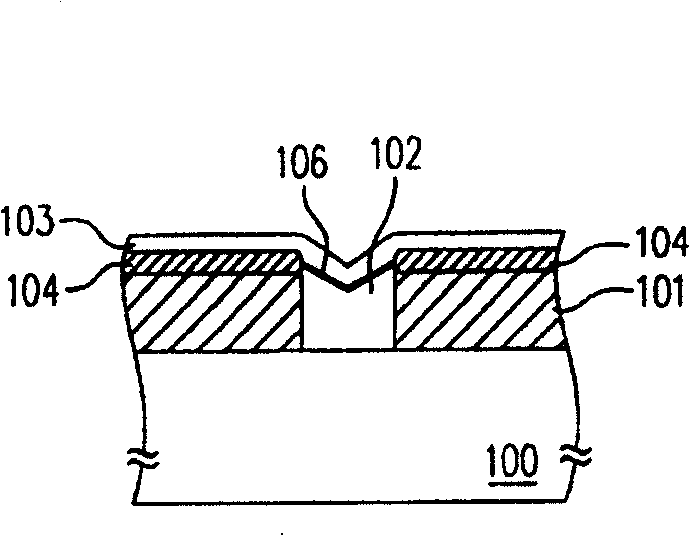

A manufacturing method and wire technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of polysilicon layer 101 short circuit connection, side diffusion, polysilicon seepage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

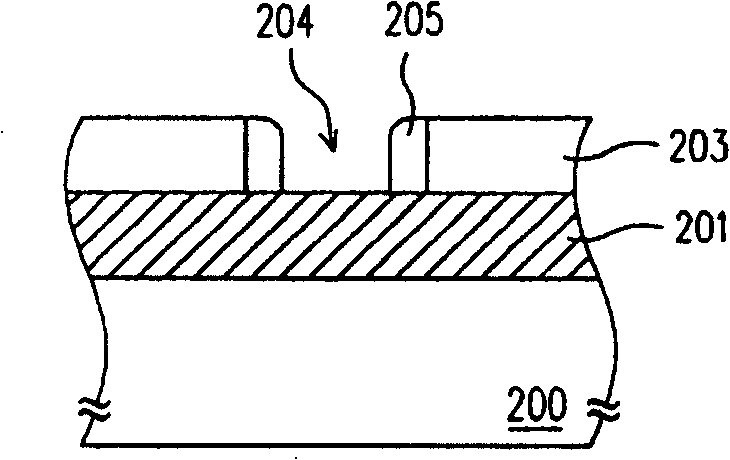

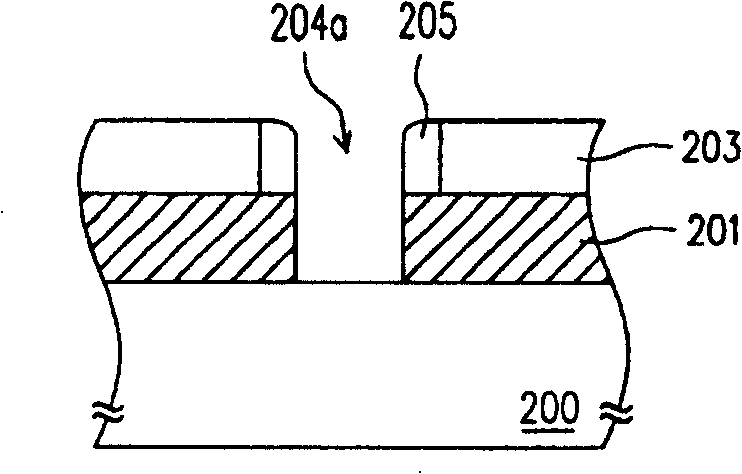

[0041] Figure 2A to Figure 2F is a cross-sectional view illustrating a manufacturing process of a wire according to a preferred embodiment of the present invention.

[0042] Please refer to Figure 2A In the method for manufacturing wires of the present invention, a substrate 200 is firstly provided, and a layer of polysilicon layer 201 has been formed on the substrate 200, and the formation method is, for example, chemical vapor deposition. Afterwards, a mask layer 203 is formed on the polysilicon layer 201 , which has an opening 204 exposing the polysilicon layer 201 . Wherein, the material of the mask layer 203 is, for example, silicon oxide or silicon nitride, and its formation method is, for example, to first form a mask material layer (not shown) by chemical vapor deposition, and then perform a photolithographic etching process to pattern the mask. mold material layer to form it.

[0043] Next, a spacer 205 is formed on the sidewall of the mask layer 203. The materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com