Recycling method of metal powder return scrap

A technology of metal powder and return material, applied in the field of recycling of metal powder return material, can solve the problems of increasing oxygen and nitrogen in molten steel, absorbing oxygen and nitrogen, large specific surface area of return material, etc. The effect of content reduction and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

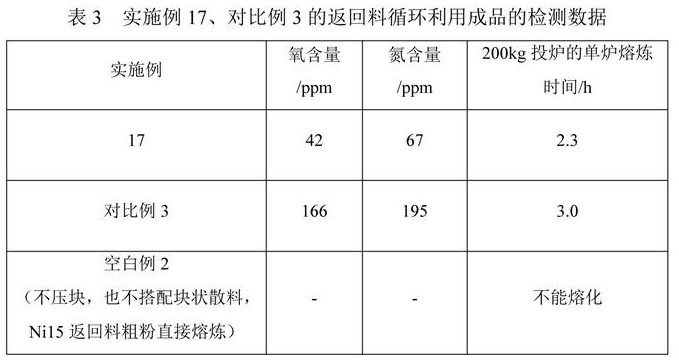

[0032] The preparation embodiment of volatilizable macromolecular material wrapping:

[0033] Embodiments 1-8 prepare volatile polymer material wrappers according to the formula in Table 1 below:

[0034]

[0035] The specific preparation process of embodiment 1-8 volatile polymer material wrapping is:

[0036] According to the formula in Table 1, add each raw material into the high-speed mixer, raise the temperature to 75°C, and mix the materials for 12 minutes, and mix the materials uniformly; transfer the uniformly mixed materials in the high-speed mixer to the internal mixer for banburying , the temperature in the internal mixer is 140°C, and the banburying time is 25min; the material after banbury mixing is sent into the extruder for extrusion operation, and the temperature of the extruder is 160°C; The material is calendered, stretched, and cooled by a calender. The roller temperature of the calender is 170°C. During the calendering and stretching, the thickness of t...

Embodiment 9

[0040] Adopt the application technical scheme to carry out the recycling of GH3536 return material, concrete method is as follows:

[0041] (1) Put the 0-15 micron and 53-250 micron GH3536 return material into the mixer, mix the mixer at a speed of 8 rpm for 3 hours, and mix the material evenly into a coarse powder;

[0042](2) Using the volatilizable polymer material sheath of Example 1 (composition: polyethylene, polyvinyl chloride, zinc stearate, paraffin), coat the coarse powder to form a powder sheath, volatilize the polymer material The weight of the package is less than 0.1%;

[0043] (3) Put the powder sheath into a mold cavity with a diameter of φ50 and a height of 50 mm, and use a press with a pressure of 200 tons to mold the powder sheath at a rate of 2 times / min; press the returned material into a block cylinder;

[0044] (4) Directly smelting the returned bulk cylinder to obtain the finished product.

Embodiment 10

[0046] The same method as in Example 9 is used to recycle the GH3536 returned material, the difference is that the "volatizable polymer material wrapper of Example 1" is replaced with "the volatilizable polymer material wrapper of Example 2".

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com