Optical close distance correction method, optical mask manufacture method and graphical method

An optical short-distance and manufacturing method technology, which is applied in the direction of optics, photographic process of pattern surface, and originals for photomechanical processing, etc., can solve the problems of semiconductor device failure and other problems, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

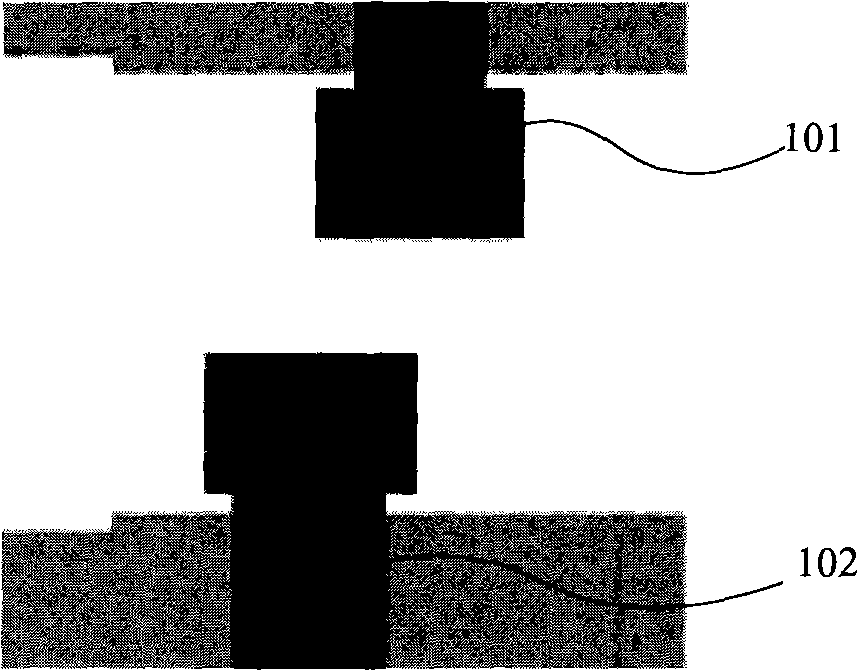

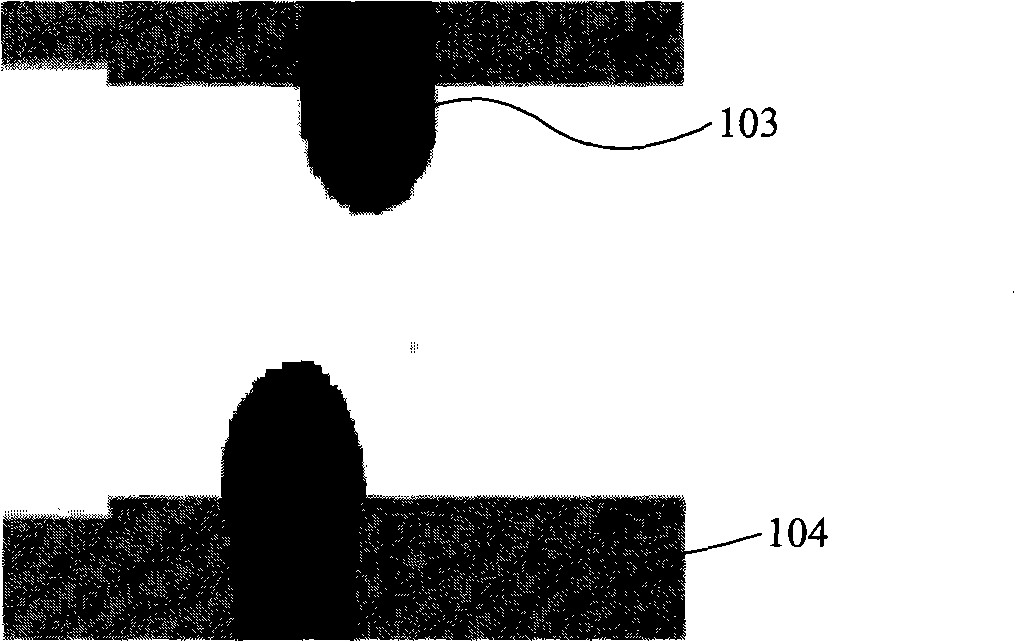

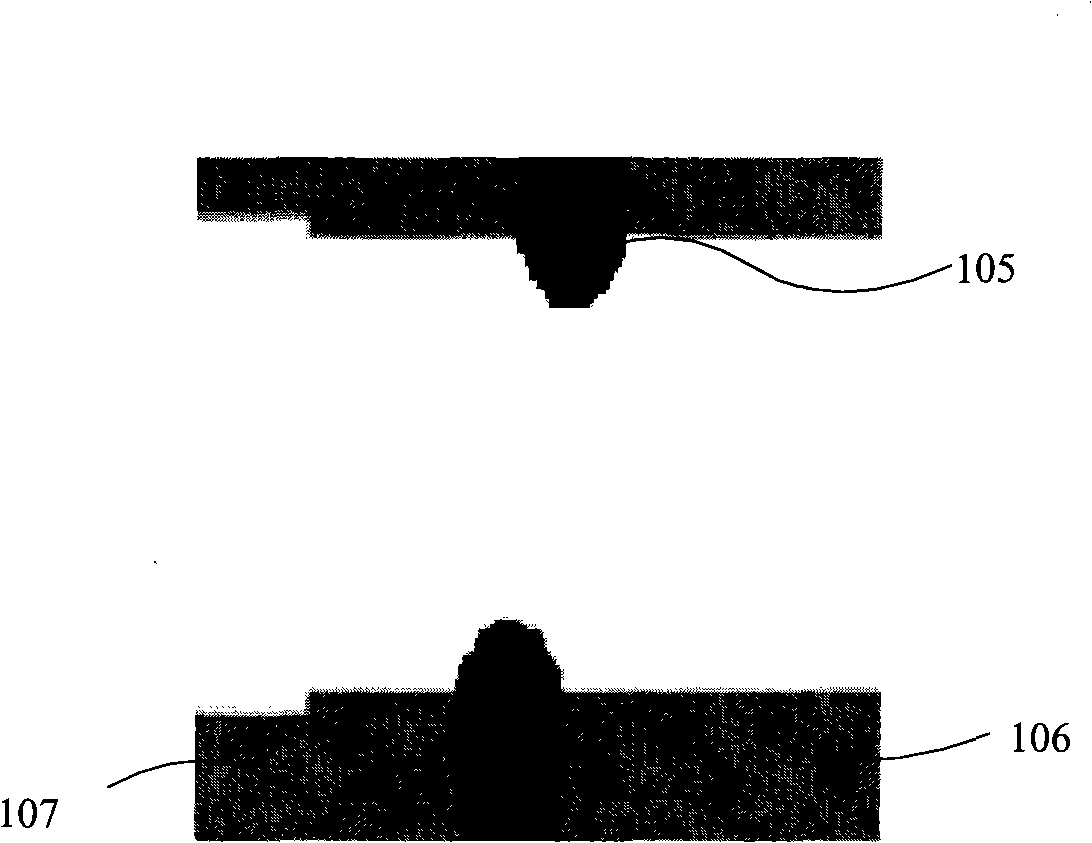

[0023] The present invention forms a corresponding layout auxiliary pattern on opposite sides of the two line ends adjacent or opposite to the layout line pattern. The line ends of the reticle circuit pattern formed on the photomask and the line pattern formed on the wafer are inclined in opposite directions, so that no bridge is generated between the line ends, and the performance of the semiconductor device is improved.

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] Figure 5 It is a flowchart of an embodiment of the present invention for optical close-range correction. Such as Figure 5 As shown, step S101 is performed to provide at least two adjacent or opposite layout line patterns; step S102 is performed to form corresponding layout auxiliary patterns on opposite sides of the two line ends.

[0026] Figure 6 It is a flowchart of an embodiment of the present invention for ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com