Welding grease for electronic industry

A technology for electronic industry and solder paste, applied in the field of solder paste for electronic industry, can solve the problem of poor storage stability of solder paste, and achieve excellent wettability, excellent storage stability, excellent wettability and storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the solder alloy powder is Sn63-Pb37, its content is 90% (mass percentage), and the content of flux is 10% (mass percentage).

[0020] The components of the flux and the content of each component are as follows:

[0021] Resin Hydrogenated rosin 35% of flux mass

[0022] Premium Rosin 19% of flux mass

[0023] Solvent Isopropanol 17% by mass of flux

[0024] Terpineol 25.6% by mass of flux

[0025] Rheology modifier Modified hydrogenated castor oil 2.95% by mass of flux

[0026] Activator Perfluorooctanoic acid 0.25% by mass of flux

[0027] Perfluoroglutaric acid 0.15% by mass of flux

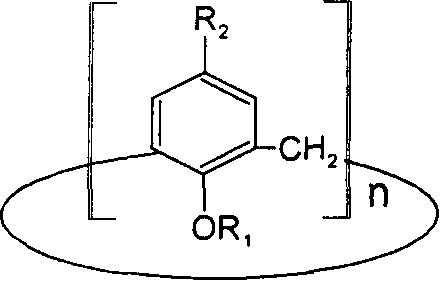

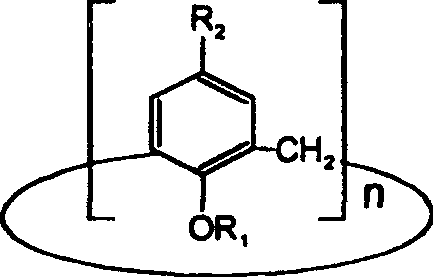

[0028] Stabilizer p-tert-butyl cup [4] 0.05% of flux mass

[0029] Thoroughly mix the above alloy solder powder and flux evenly to prepare solder paste. The product should be kept refrigerated below 5°C.

Embodiment 2

[0031] In this embodiment, the alloy solder powder is Sn95.5-Ag3.8-Cu0.7, its content is 85% (mass percentage), and the content of solder is 15% (mass percentage).

[0032] The components of the flux and the content of each component are as follows:

[0033] Resin polyacrylate 20% of flux mass

[0034] Polyurethane 25% by mass of flux

[0035] Solvent diethylene glycol ether 40% of flux mass

[0036] Rheology modifier Hydrogenated castor oil 5% of flux mass

[0037] Activator tert-butyl perfluoroglutarate 4% by mass of flux

[0038] Perfluoroadipic acid 4% by mass of flux

[0039] Stabilizer p-tert-butyl cup [6] 2% of flux mass

[0040] Thoroughly mix the above alloy solder powder and flux evenly to prepare solder paste. The product should be kept refrigerated below 5°C.

Embodiment 3

[0042] In this embodiment, the solder alloy powder is Sn91.8-3.4Ag-4.8Bi, its content is 94% (mass percentage), and the content of solder is 6% (mass percentage).

[0043] The components of the flux and the content of each component are as follows:

[0044] Resin Polymerized rosin 45% of flux mass

[0045] Solvent methyl cellosolve 38.5% of flux mass

[0046] Rheology modifier Hydrogenated castor oil 8% by mass of flux

[0047] Activator Perfluoroglutaric acid 1.5% by mass of flux

[0048] tert-butyl perfluoroadipate 3% by mass of flux

[0049] Stabilizer p-phenyl cup [4] 3.95% of flux mass

[0050] Fluorosurfactant Perfluorobetaine 0.05% of flux mass

[0051] Thoroughly mix the above alloy solder powder and flux evenly to prepare solder paste. The product should be kept refrigerated below 5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com