Surface-mounted microwave circulator

A circulator, mount-type technology, applied in the field of new surface-mounted microwave circulators, can solve problems such as poor welding between the shell and the circuit board, misalignment of the surface circulator, and low production efficiency, achieving good consistency and improving The effect of improving reliability and welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

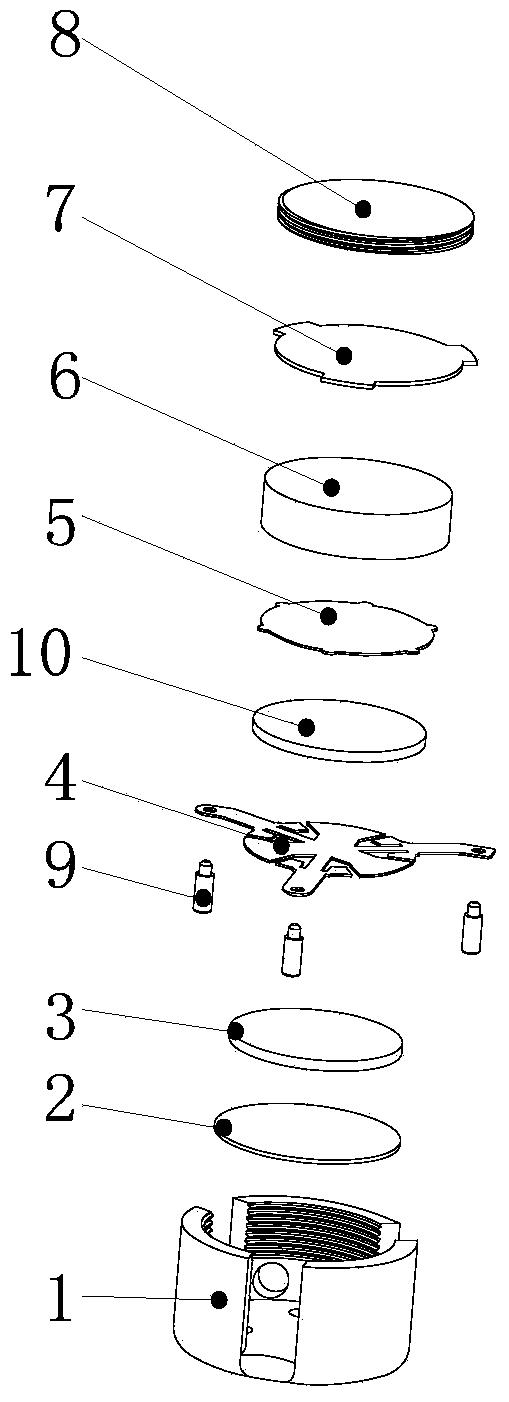

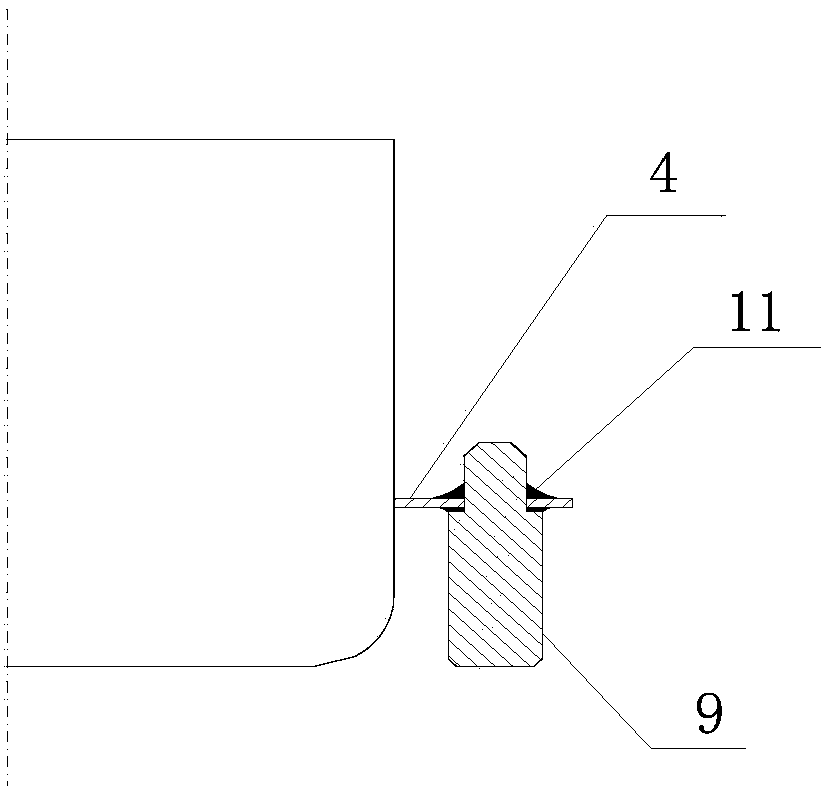

[0013] Such as figure 1 As shown, the surface-mounted microwave circulator includes a housing 1 and a cover plate 8 located thereon. The housing 1 has a semi-open cylindrical cavity structure, and the side wall of the housing 1 is provided with 3 openings. 1, a gasket 2, a lower ferrite 3, a central conductor 4, an upper ferrite 10, a homogeneous conductive sheet 5, a permanent magnet 6 and a temperature compensation sheet 7 are placed in sequence in the semi-open cylindrical cavity of 1, and the permanent magnet 6 is Single-magnet magnetic circuit structure, the center conductor 4 protrudes out of the cavity through the opening on the side wall of the housing, the end of the center conductor 4 is welded with a columnar joint 9, the axis of the columnar joint 9 is at a 90-degree right angle to the plane of the center conductor 4, forming The cylindrical connector port presents an RF impedance of about 50 ohms relative to the RF signal.

[0014] Put the gasket 2, the lower fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com