Conductive paste for solar cells and preparation method thereof

A solar cell and conductive paste technology, applied in the field of solar cells, can solve problems such as low welding strength, decreased battery performance, and reduced density, and achieve the effects of high welding strength, improved battery performance, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

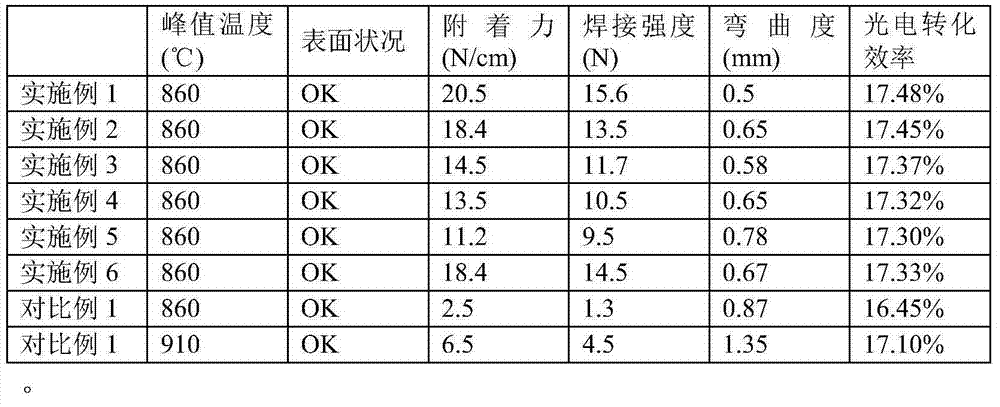

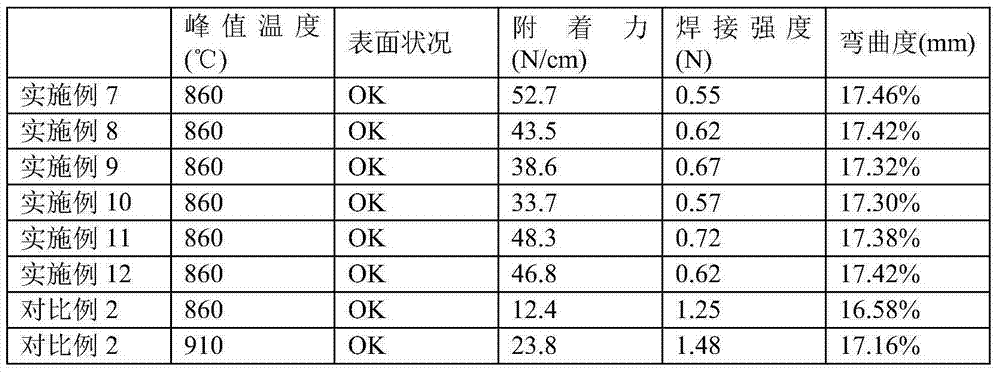

Examples

preparation example Construction

[0021] Simultaneously, the present invention provides the preparation method of above-mentioned conductive paste for solar cell, and the step comprises:

[0022] S1. Mix the solution containing metal nitrate with the mixture of silicate and borate under the condition of pH = 0.5-2 to obtain a gel system; the mixing method of the present invention is not particularly limited, and various methods known to those skilled in the art can be used. For example, the acid can be mixed with the metal nitrate first, and then mixed with the mixture of silicate and borate to control the mixing rate, ensure the pH value of the reaction system, and form a uniform gel system. Mix the acid with the mixture of silicate and borate, control the pH value of the reaction system, react for 1 to 2 hours, hydrolyze part of the silicate and borate in advance, and then add metal nitrate under the condition of stirring and heating , add acid at the same time, control the pH value of the reaction system, a...

Embodiment 1

[0034] To the glossy silver conductive paste.

[0035] (1) Preparation of inorganic glass powder

[0036] According to the mass ratio of nitric acid (concentration: 50wt%): glacial acetic acid (concentration: 99.5wt%): deionized water = 1:1:100 dilution, to obtain a mixed acid solution.

[0037] Take by weighing 55 parts by mass of bismuth nitrate, 8 parts by mass of zinc nitrate, and 5 parts by mass of aluminum nitrate, add deionized water to dissolve and stir evenly, the amount of deionized water is 2.5 times of the total amount of metal nitrate, to obtain metal nitrate aqueous solution.

[0038] Weigh 20 parts by mass of butyl borate and 12 parts by mass of ethyl silicate, add ethanol according to the mass sum of ethyl silicate and butyl borate: ethanol = 1:2, mix and stir evenly.

[0039] Add mixed acid dropwise to the mixed solution of ethyl silicate, butyl borate and metal nitrate aqueous solution, and stir evenly to make the pH of the solution 1.5. The stirring time i...

Embodiment 2

[0046] Silver conductive paste for glossy surface

[0047] The same method as in Example 1 was used to prepare the glossy silver conductive paste, except that mixed acid was added dropwise in the preparation of the inorganic glass powder to make the pH of the gel reaction system 0.5.

[0048] Adopt the method identical with embodiment 1 to test inorganic glass powder, record the medium particle diameter D of the inorganic glass powder of preparation 50 123.2nm, D 10 at 26.2nm, D 90 At 482.6nm, the specific gravity of the glass powder is 6.79, and the softening point is 414°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com