Method for fabricating bump

A fabrication method and bump technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as affecting reliability, short-circuiting semiconductor devices, affecting the electrical properties of copper metal layers, etc., to achieve reliability assurance , avoid short circuit, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

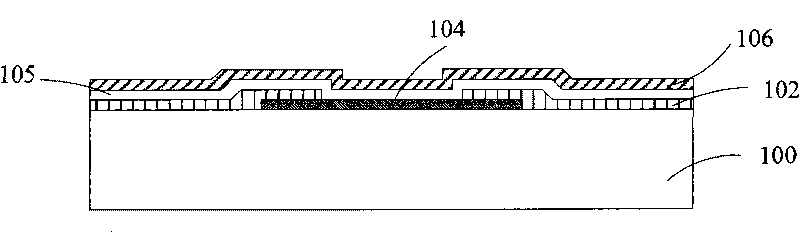

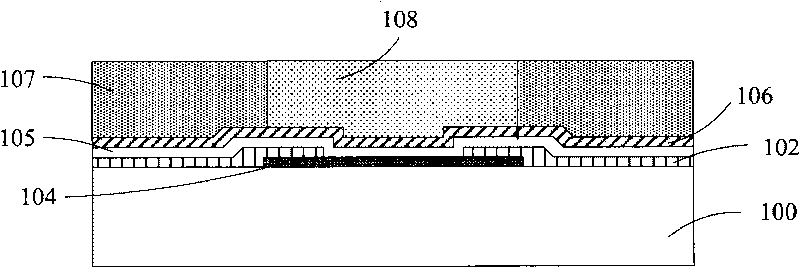

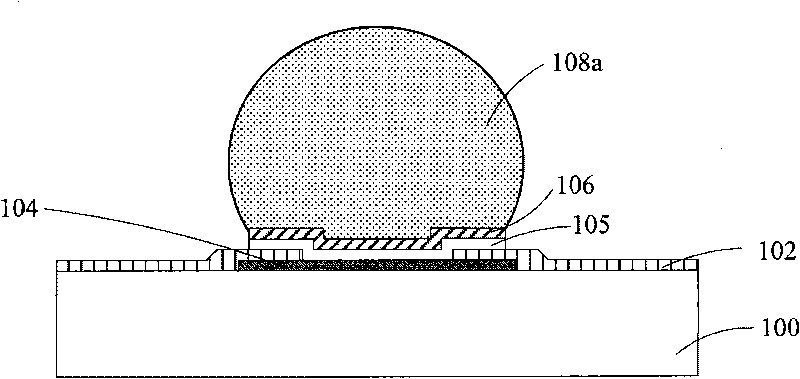

Embodiment Construction

[0022] Flip-chip technology is gaining more and more attention because it can reduce the size of the package. As a key technology in flip-chip manufacturing technology, the quality of bump production directly affects the quality of flip-chip. In the invention, the opposite surface of the surface where the solder layer of the chip is located is in contact with and fixed to the hot plate of the reflow furnace, and the chip is located under the hot plate. Due to the inversion of the solder layer, the solder layer will only flow downward under the influence of gravity during the reflow process, and will not penetrate into the UBM layer, so that the reliability of the UBM layer is guaranteed; at the same time, the solder layer After inversion, the bumps formed by reflow will not produce bridging phenomenon, avoiding the occurrence of short circuit; in the process of making copper pillar bumps, the inversion of the solder layer will prevent the solder layer from flowing along the ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com