Packaging and stacking device and method for manufacturing same

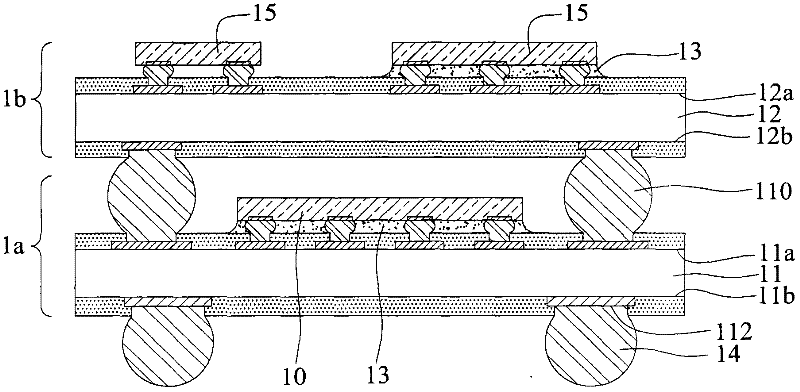

A stacking and stacking technology, which is applied in the field of package stacking device and its manufacturing method, can solve problems such as inclined placement, influence on product yield, difficult control of solder ball 110 size variation, etc., and achieve the effect of avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The implementation of the present invention will be described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

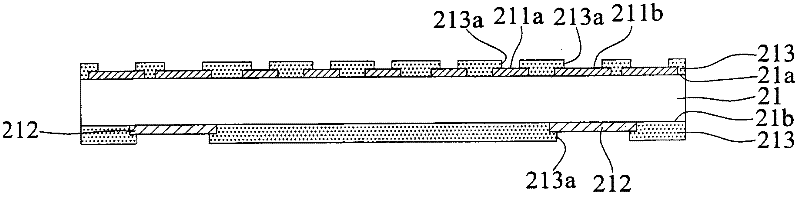

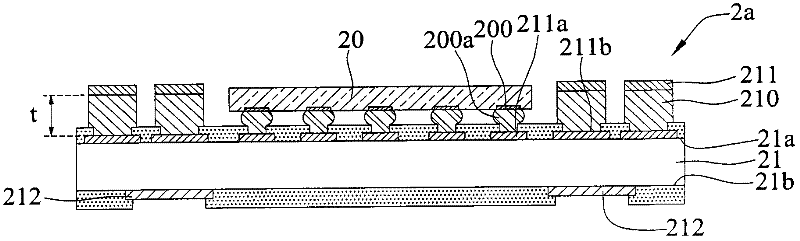

[0061] see Figure 2A to Figure 2G , which is a schematic cross-sectional view of the first embodiment of the manufacturing method of the package stacking device of the present invention.

[0062] Such as Figure 2A As shown, firstly, a first substrate 21 having opposite first surface 21a and second surface 21b is provided, on the first surface 21a of the first substrate 21 there are a plurality of welding pads 211a and electrical contact pads 211b, and The second surface 21 b of the first substrate 21 has a plurality of ball planting pads 212 .

[0063] In this embodiment, the first and second surfaces 21a, 21b of the first substrate 21 have an insulating protective layer 213 such as a solder resist layer, and the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com