Salient point and forming method thereof

A technology of bumps and metal layers under bumps, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as bridging of bumps, short circuits, and affecting the electrical performance of semiconductor devices, so as to avoid short circuits, The effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

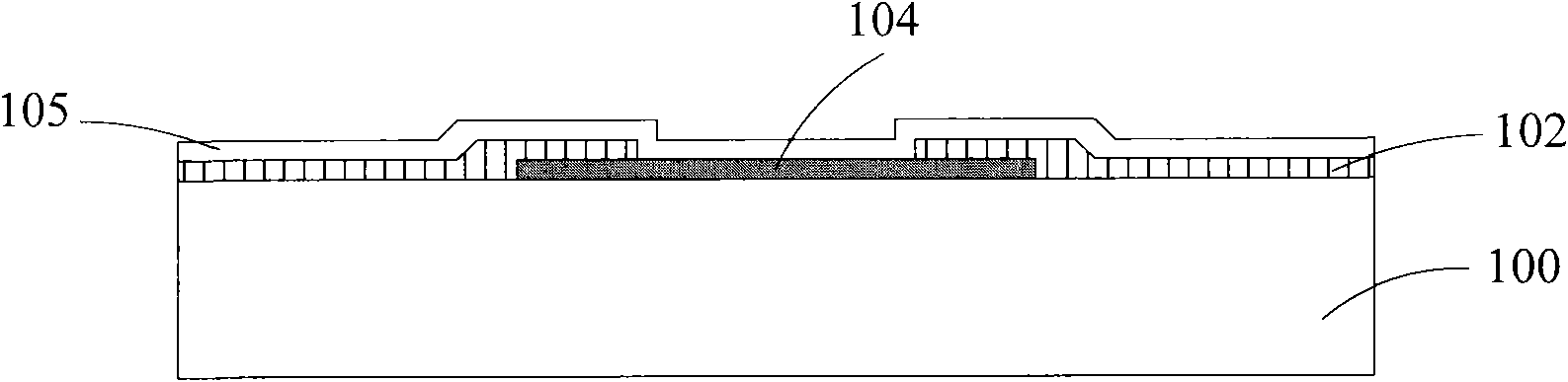

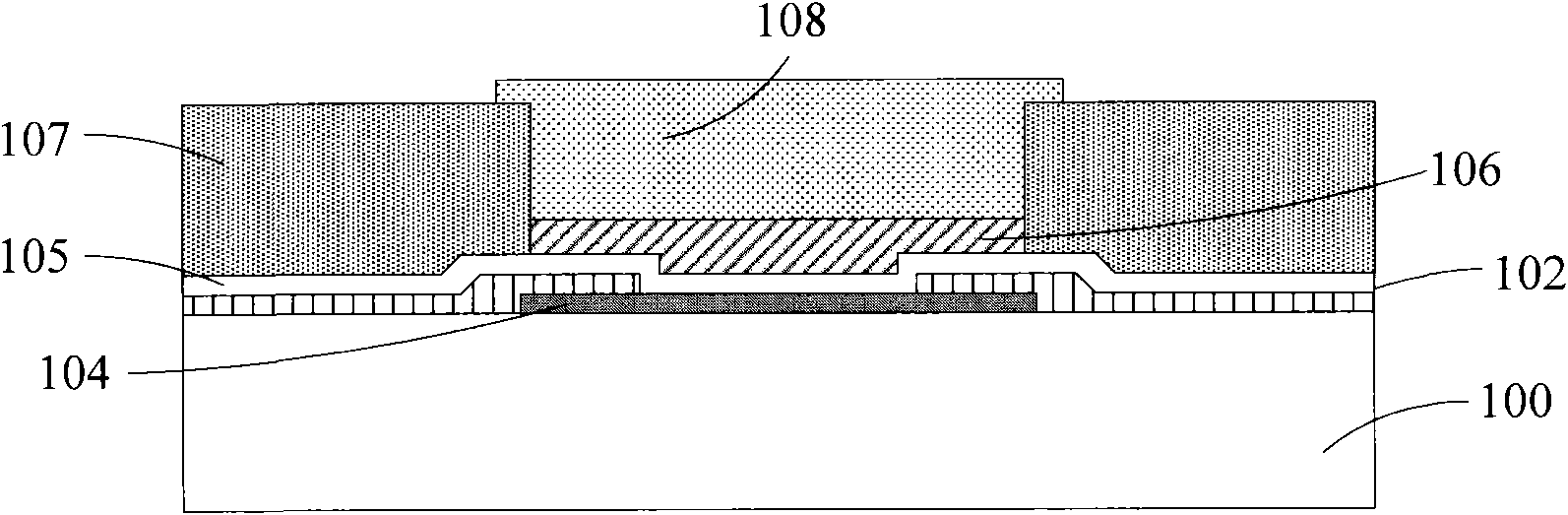

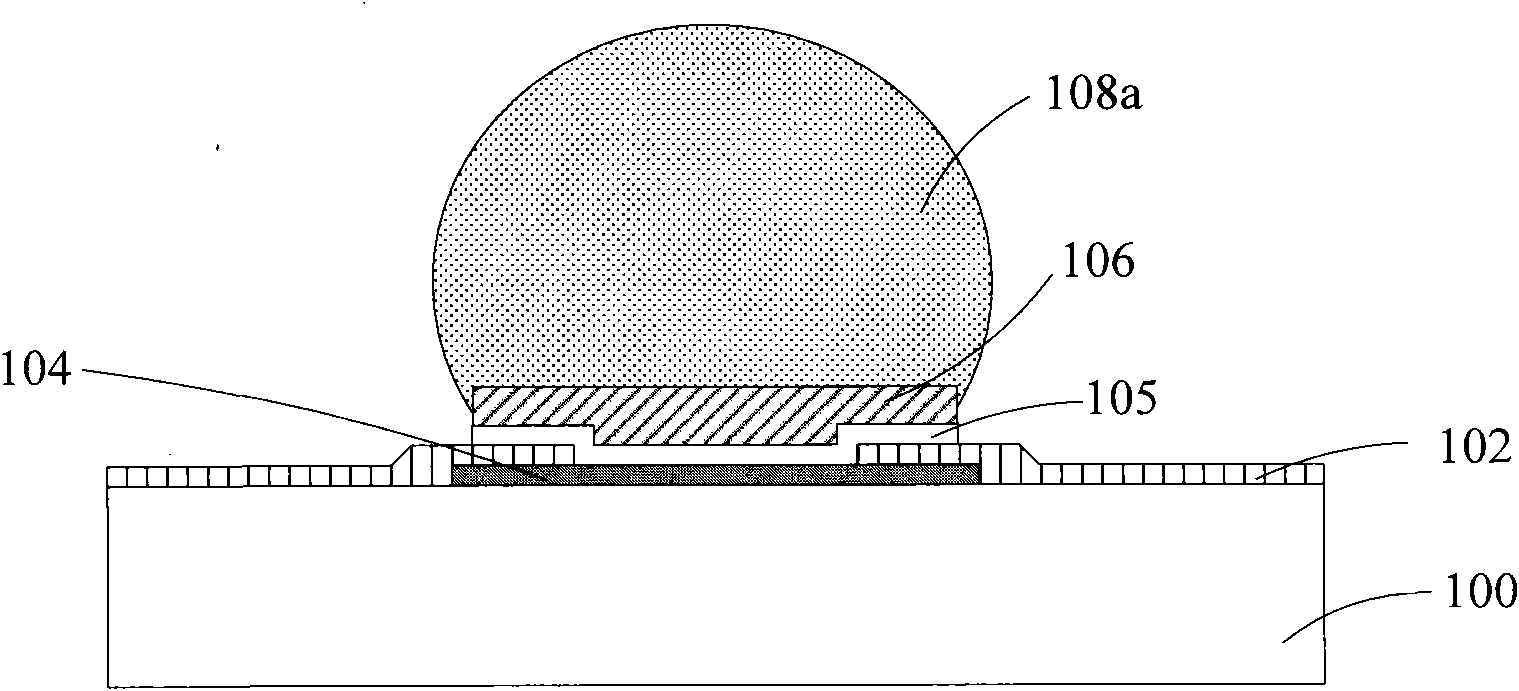

[0027] The present invention provides the concrete flow process of making bump as Figure 4 As shown, step S11 is performed to provide a semiconductor substrate, on which a metal pad layer and a passivation layer are formed, the metal pad layer is embedded in the passivation layer, and exposed through the opening on the passivation layer metal pad layer; perform step S12, form a metal shielding layer on the metal pad layer and the passivation layer in the opening of the passivation layer; perform step S13, form a photoresist layer on the metal shielding layer, on the photoresist layer There is an opening corresponding to the position of the metal pad layer; perform step S14, form a seed layer and an under-bump metal layer on the metal shielding layer in the opening of the photoresist layer; perform step S15, after removing the photoresist layer, etch Removing the metal shielding layer other than the position of the metal pad layer; performing step S16, forming sidewalls on bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com