Salient point and formation method thereof

A technology of bumps and metal layers under bumps, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc. The effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

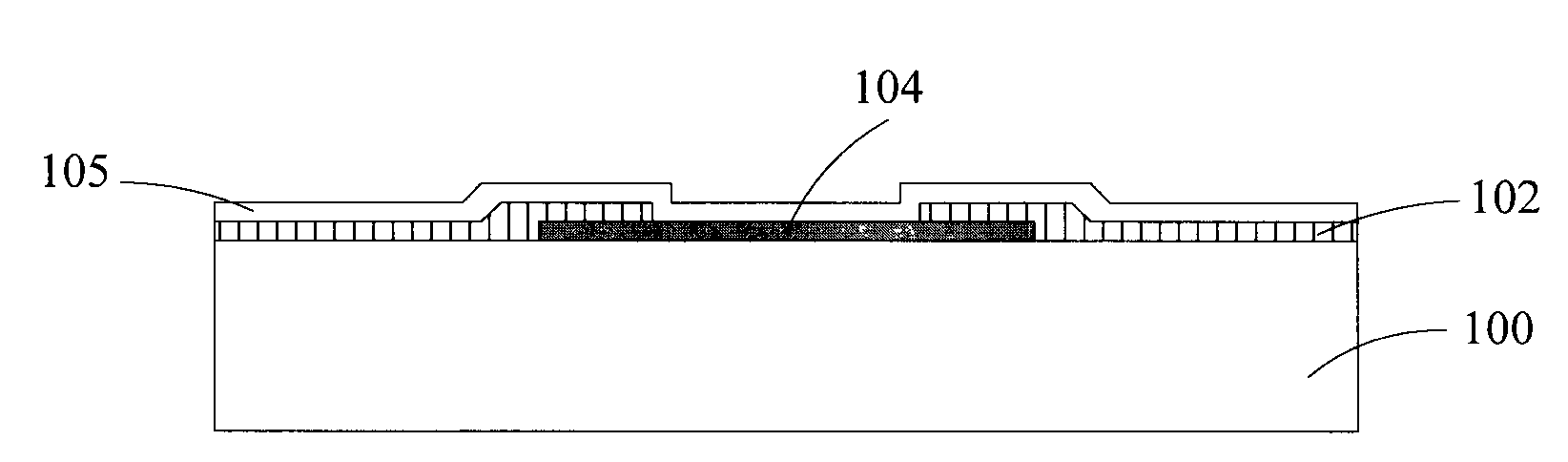

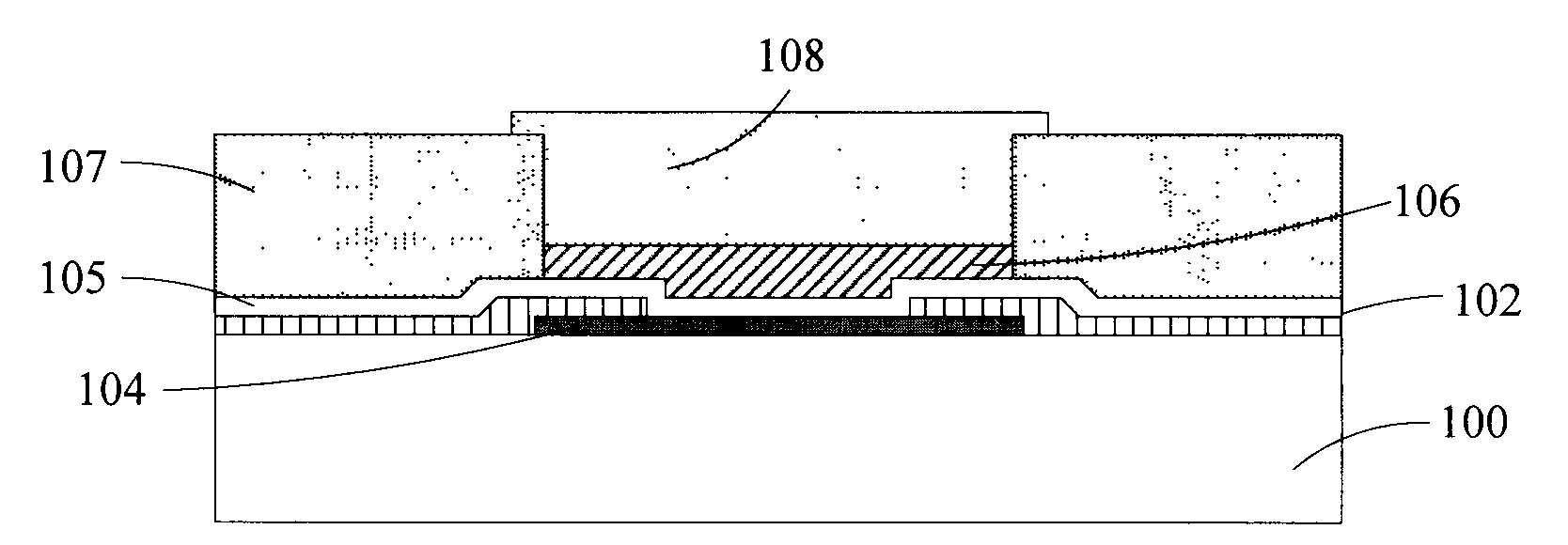

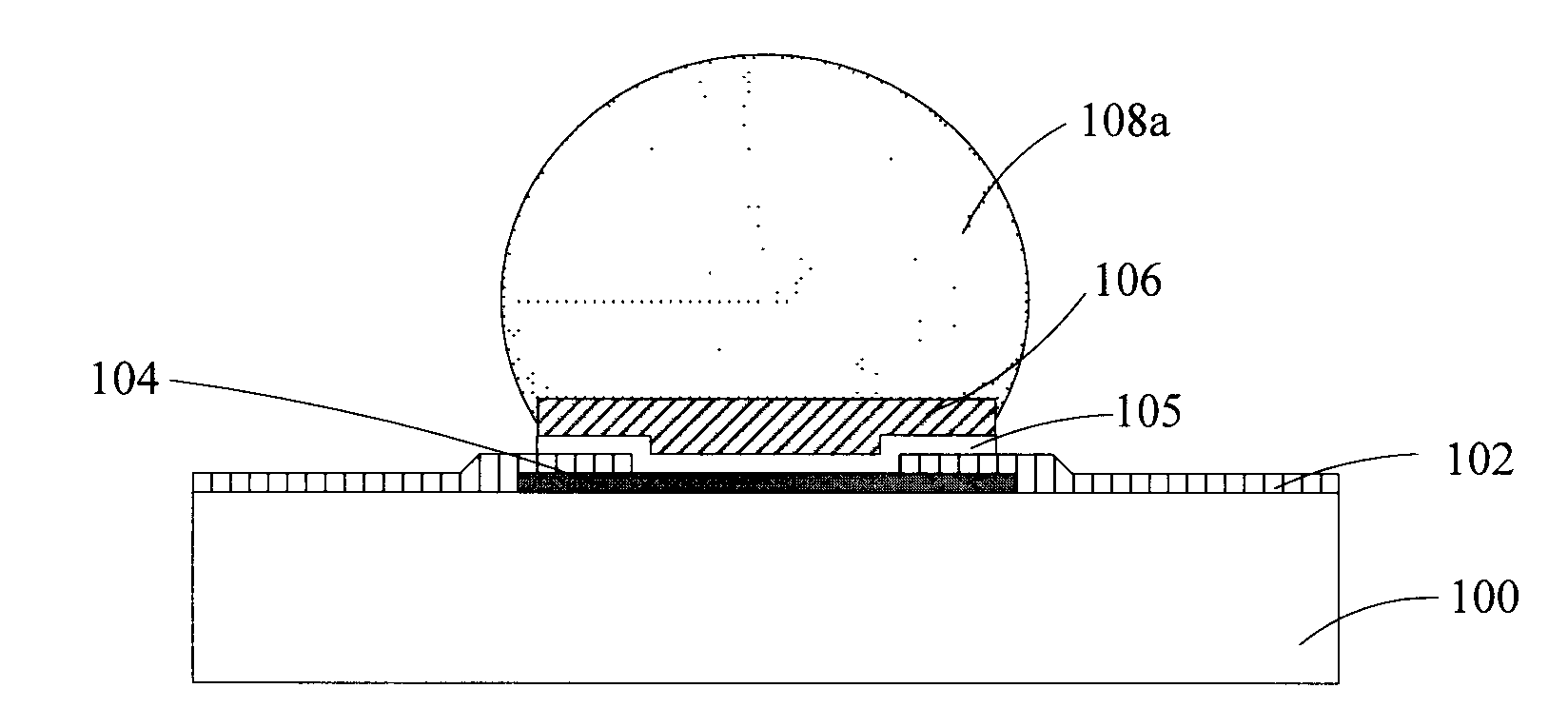

[0028] The present invention provides the concrete flow process of making bump as Figure 4 As shown, step S11 is performed to provide a semiconductor substrate, on which a metal pad layer and a passivation layer are formed, the metal pad layer is embedded in the passivation layer, and exposed through the opening on the passivation layer metal pad layer; perform step S12, form a metal shielding layer on the metal pad layer and the passivation layer in the opening of the passivation layer; perform step S13, form a photoresist layer on the metal shielding layer, on the photoresist layer There is an opening corresponding to the position of the metal pad layer; perform step S14, form a seed layer and an under-bump metal layer on the metal shielding layer in the opening of the photoresist layer; perform step S15, after removing the photoresist layer, etch removing the metal shielding layer other than the position of the metal pad layer; performing step S16, forming sidewalls on bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com