Flexible die for molded composite material stringer and preparation method thereof

A composite material and flexible mold technology, applied in the field of process manufacturing, can solve the problems of low rigidity of rubber soft mold, difficult positioning, unsatisfactory axiality and straightness of long truss, etc. Quality, the effect of realizing mold positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

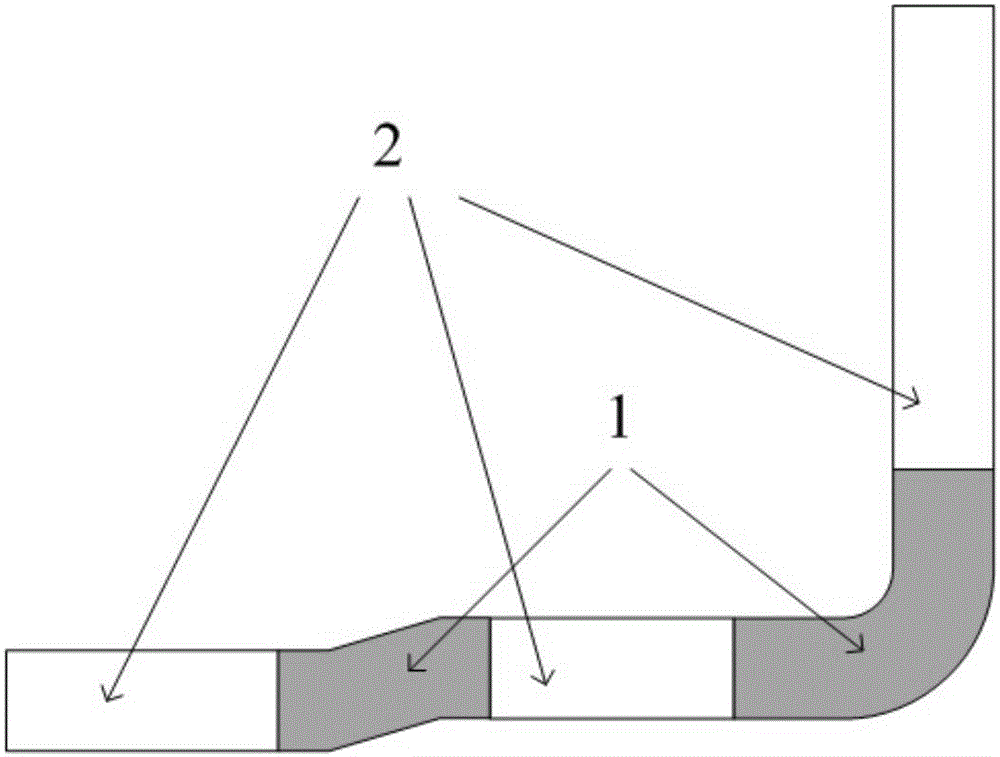

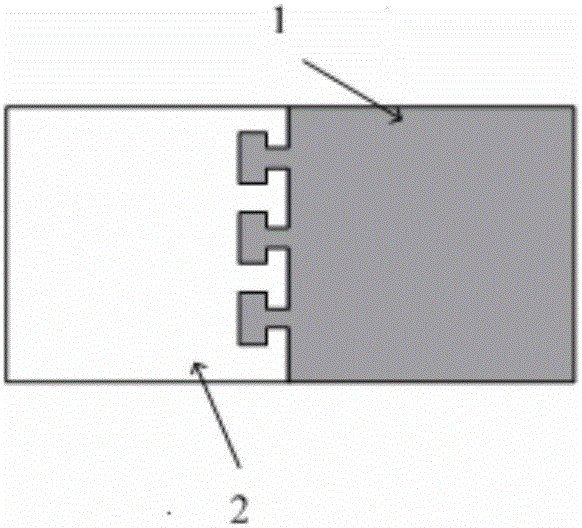

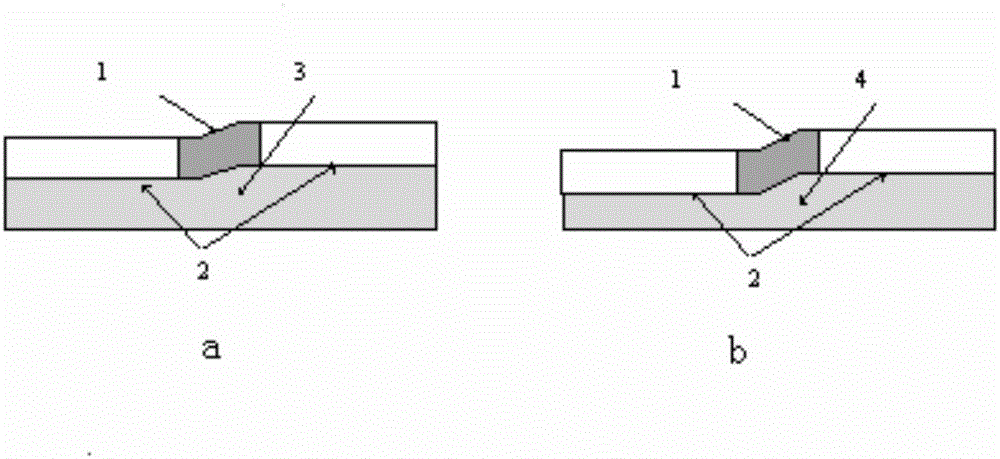

[0029] like Figure 1-2 As shown, the present invention is a flexible mold for molding composite stringers, the flexible mold includes at least one molding unit; the section of the molding unit is L-shaped, and the L-shaped molding unit includes at least one flexible module and two a rigid module, the two rigid modules are connected by a flexible module, and the ends of the L-shaped forming units are all rigid modules;

[0030] Wherein, the rigid module corresponds to the region of equal thickness of the composite stringer flange and the web, and the flexible module corresponds to the corner region of the composite stringer and the thickness change transition region.

[0031] The size of the flexible module is larger than its corresponding composite material stringer corner area and the transition area of flange and web thickness change, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com