Machining deformation precision control method for super-long large-diameter concrete tube pile steel mould

A concrete pipe pile, precision control technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty in quality control, increased risk, high requirements, etc., to overcome the difficult control of deformation precision, improve production efficiency, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

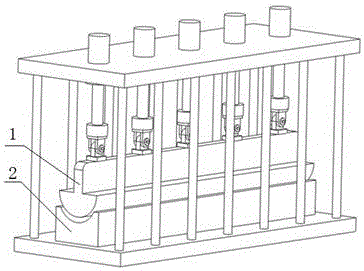

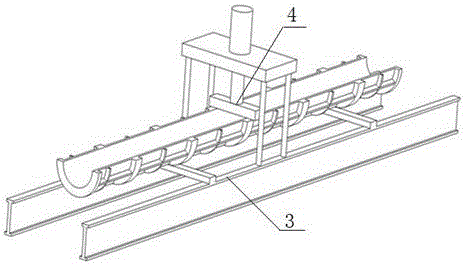

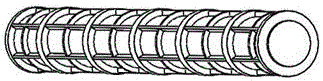

Embodiment 1

[0030] Φ1400×390000 pre-tensioned prestressed concrete pipe pile steel mold processing: steel mold processing is carried out according to the following procedures: 1. Cutting preparation, including semicircular steel mold cylinder, ring reinforcement, longitudinal reinforcement, tongue and groove plate, end connection Plates, running wheels, ribs, clamping bolts. The semi-circular steel mold cylinder is pressed on a 6-meter-long pressure forming machine. 2. Spot installation, hoist the semicircular steel mold cylinder, tongue and groove plate, running wheel, longitudinal rib, ring rib and rib plate to the spot loading platform in sequence, and spot weld them firmly according to the design requirements. The corresponding clamping molds of the two semicircular steel mold cylinders are connected into a complete circle by clamping bolts. 3. Welding, hoist the spot-welded steel mold to the large welding frame, and complete the welding according to the symmetrical welding sequence ...

Embodiment 2

[0045] Φ1200×44600 pre-tensioned prestressed concrete pipe pile steel mold processing is carried out according to the following procedures: 1. Cutting preparation, including semi-circular steel mold cylinder, ring reinforcement, longitudinal reinforcement, tongue and groove plate, end connection plate , running wheels, ribs, clamping bolts. The semi-circular steel mold cylinder is pressed on a 6-meter-long pressure forming machine. 2. Spot installation, hoist the semicircular steel mold cylinder, tongue and groove plate, running wheel, longitudinal rib, ring rib and rib plate to the spot loading platform in sequence, and spot weld them firmly according to the design requirements. The corresponding clamping molds of the two semicircular steel mold cylinders are connected into a complete circle by clamping bolts. 3. Welding, hoist the spot-welded steel mold to the large welding frame, and complete the welding according to the symmetrical welding sequence welding process. 4. Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com