Automatic tracking type laser welding method for micro-slender weld joint of nuclear reactor coolant pump

A coolant pump and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unqualified welds, deviations between laser beams and weld tracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

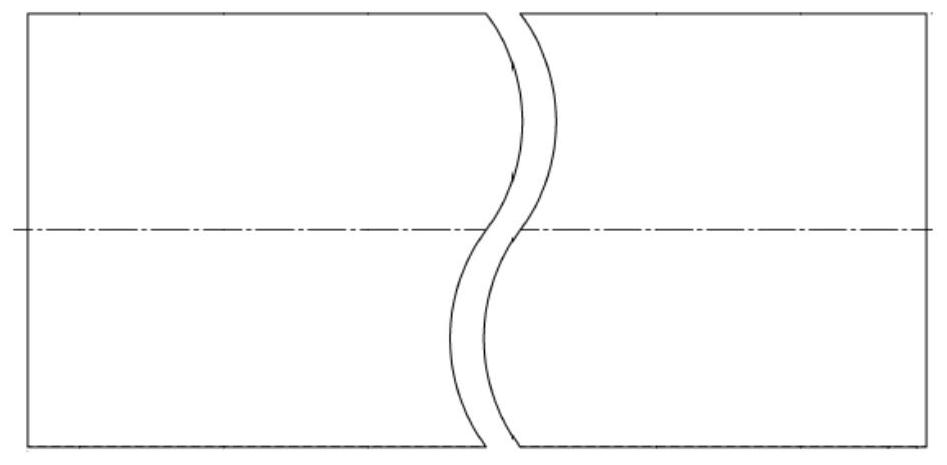

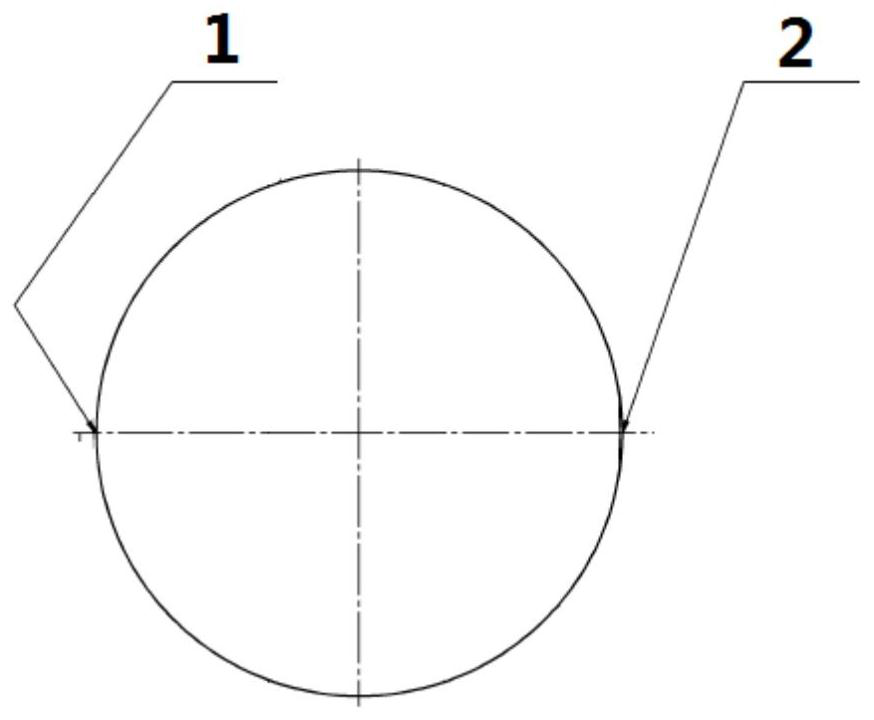

[0023] The shielding sleeve is a cylindrical piece spliced by two shielding sleeve plates. For the form of the cylindrical piece, see figure 1 , the shielding sleeve plate contains two fine long-distance welds, the positions of the first weld 1 and the second weld 2 are shown in figure 2 , the specific implementation plan is as follows:

[0024] (1) The continuous laser welding process is adopted. Applicable base metal thickness < 1mm, weld length less than 4000mm, I-shaped groove, assembly gap less than 0.1mm;

[0025] (2) Use the fine seam tracker for real-time automatic tracking, and complete the automatic adjustment of the beam during the welding process of the fine long-distance seam;

[0026] (3) Welding parameters: using the orthogonal method, defocus amount: +5 ~ +8mm; continuous laser output power is set to 400w ~ 700w; welding speed 300 ~ 400mm / min; welding shielding gas adopts argon-helium mixture, the composition 50% Ar+50% He, gas flow 25~35CHF; high-purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com