Improved mechanical equipment for indoor building painting

A kind of mechanical equipment, painting technology, applied in the direction of construction, building structure, etc., can solve the problems of poor operation flexibility, large difference in effect, influence, etc., and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

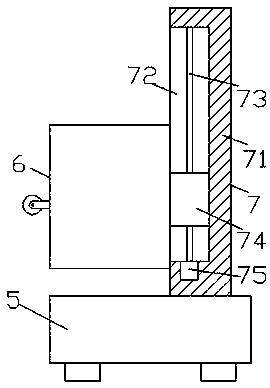

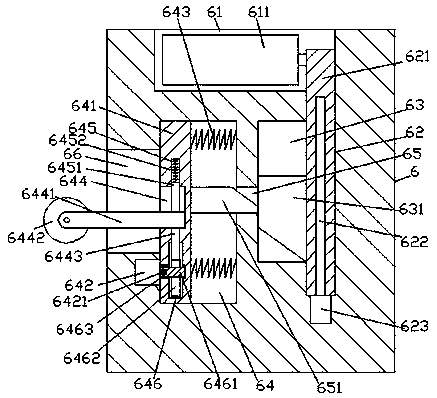

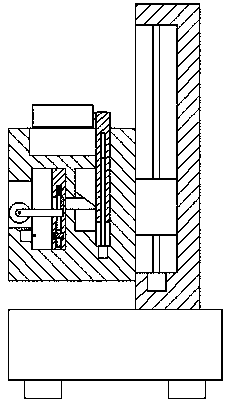

[0015] like figure 1 , figure 2 and image 3 As shown, an improved mechanical equipment for indoor building painting of the present invention includes a loading car body 5, a lifting drive mechanism 7 fixedly installed on the top of the loading car body 5, and a lifting drive mechanism installed on the left side of the lifting drive mechanism 7. The brushing machine body 6 at the end, the top end surface of the brushing machine body 6 is provided with a first accommodating cavity 61, and the inner bottom wall on the right side of the first accommodating cavity 61 is communicated with a first chute 62 extending downwards. A first slide bar 621 extending up and down is connected to the first chute 62 by sliding fit. The side section is provided with a first roller brush 611 that is rotatably connected to the first slide bar 621, and the bottom end surface of the first slide bar 621 is internally threaded and connected with an adjusting screw 622 that extends downward. The ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com