Front axle swing type paddy field four-wheel drive chassis steering system

A steering system and front axle technology, applied in the field of agricultural machinery, can solve the problems of laborious steering, easy damage to the physical structure of the soil, high labor intensity, etc., and achieve the effects of good traction adhesion, flexible and convenient operation, and good chassis stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

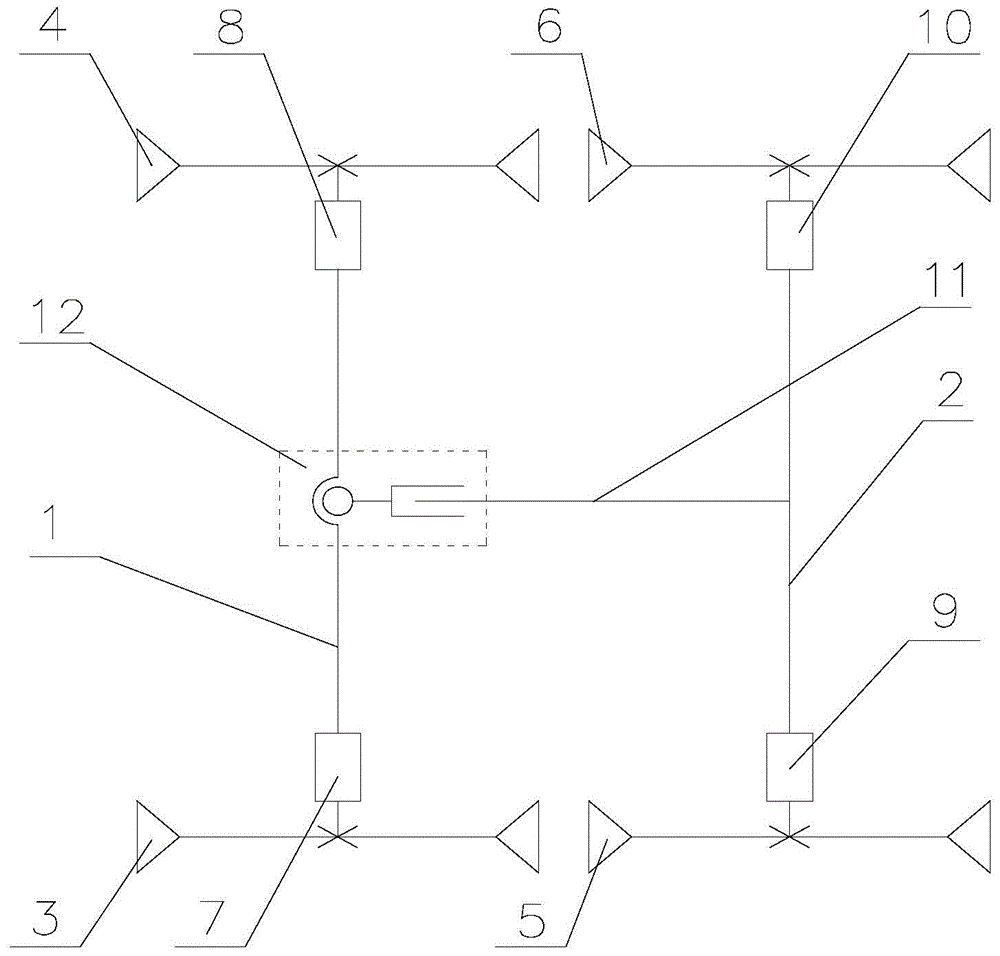

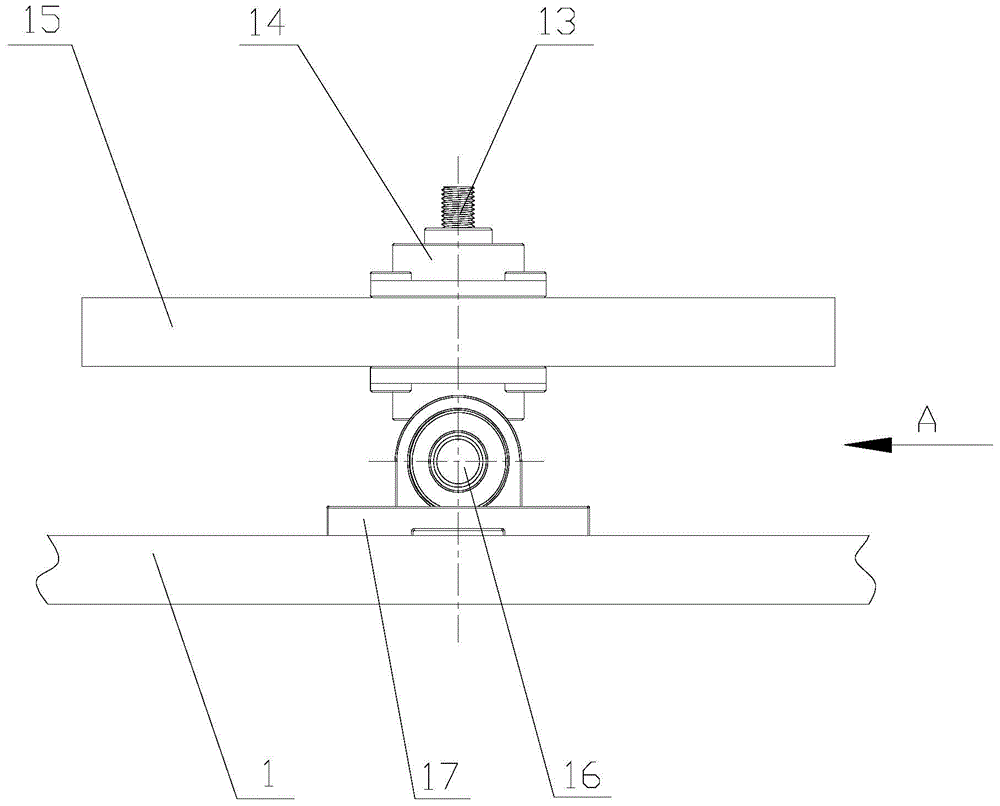

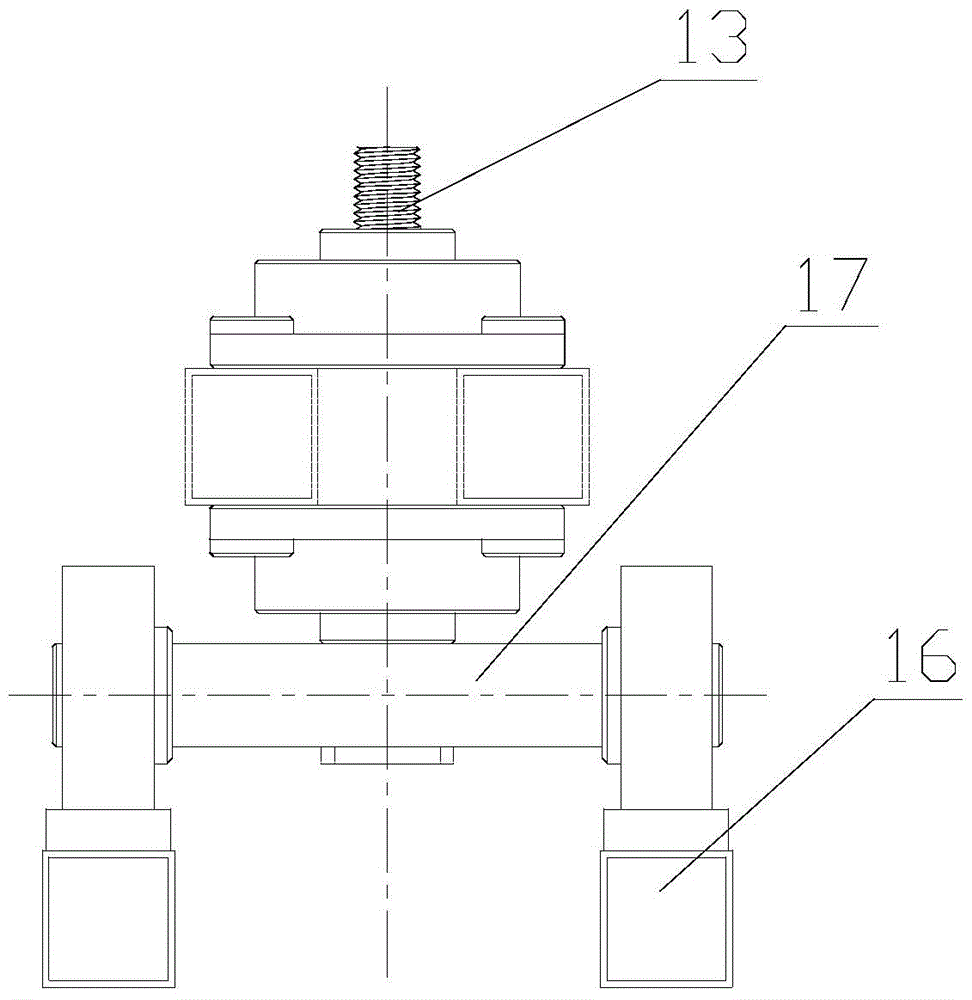

[0025]In this embodiment, a front axle swing type paddy field four-wheel drive chassis steering system includes a front axle 1, a rear axle 2, a left front wheel 3, a right front wheel 4, a left rear wheel 5 and a right rear wheel 6, and the left front wheel and The right front wheel is respectively arranged at the left and right ends of the front axle, the left rear wheel and the right rear wheel are respectively arranged at the left and right ends of the rear axle, and the front axle and the rear axle are respectively fixed on the vehicle frame; The left rear wheel and the right rear wheel are respectively equipped with independent hydraulic motors, and each hydraulic motor is connected to the hydraulic oil circuit; the hydraulic motor corresponding to the left front wheel is the left front hydraulic motor 7, and the hydraulic motor corresponding to the right front wheel is the right front hydraulic motor. Motor 8, the hydraulic motor corresponding to the left rear wheel is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com