Automatic control method of 300 MW grading circulating fluidized bed units

A circulating fluidized bed and automatic control technology, which is applied to electric controllers, fluidized bed combustion equipment, and electric temperature control, etc., can solve the problems of complex coupling relationship and the complexity of the combustion system of circulating fluidized bed boilers. , to achieve the effect of high distribution accuracy and good operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

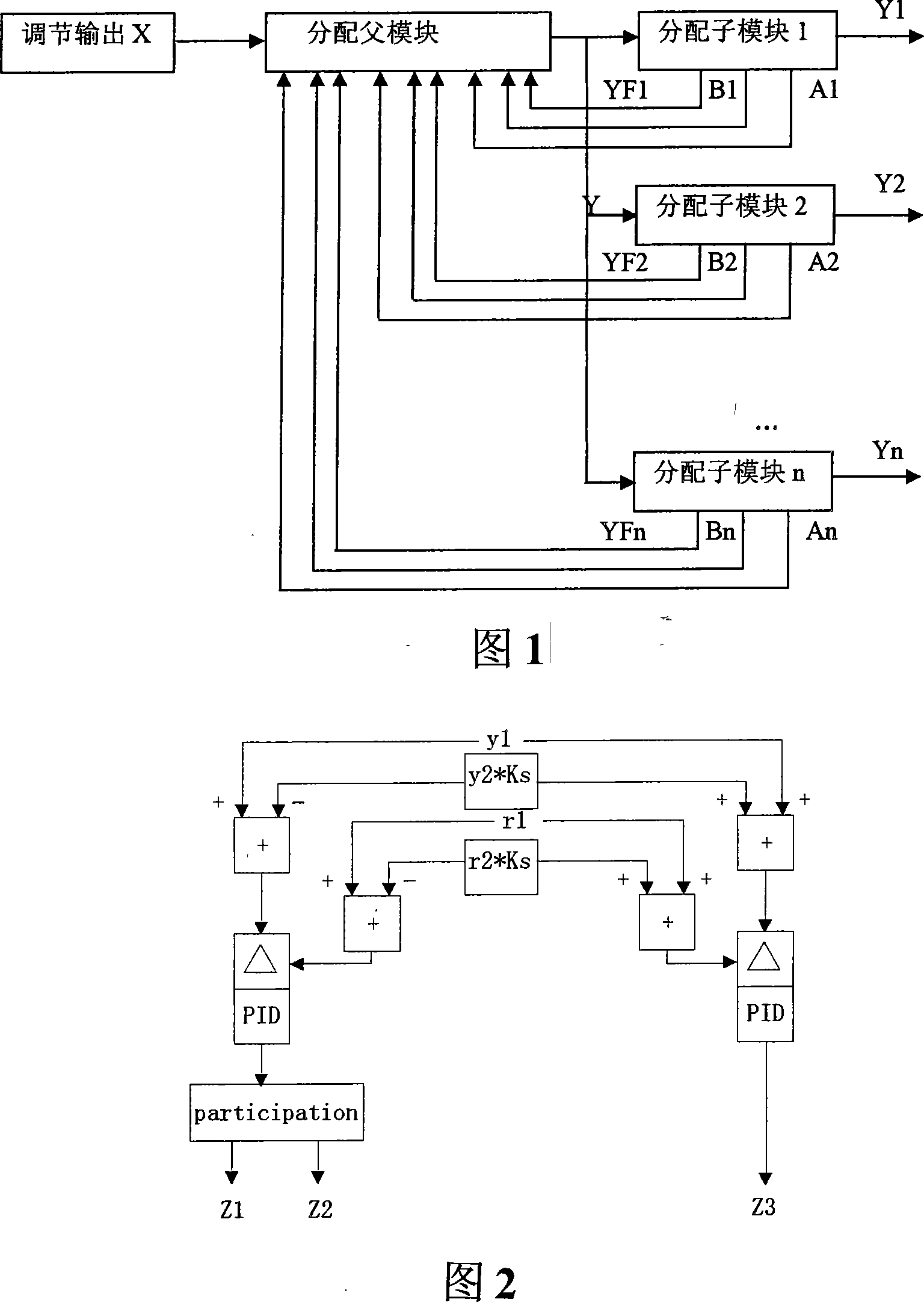

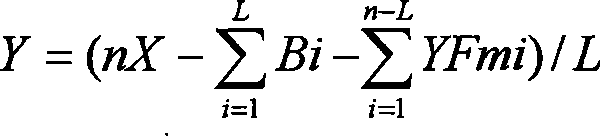

Image

Examples

Embodiment Construction

[0027] (1) Coordinated automatic control of machines and furnaces

[0028] Improved direct energy balance machine-furnace coordination control method. The steam turbine side load formed by the primary pressure of the steam turbine is used, and the steam drum pressure differential is multiplied by the heat storage coefficient of the boiler to form the heat load of the boiler, which is used as the adjusted quantity of the fuel adjustment in the coordinated control; in the furnace and machine coordination mode The boiler load command composed of four parts superimposed is used as the setting value of fuel adjustment: the current load command of the unit, the change rate of the current load command of the unit multiplied by the compensation coefficient, the change rate of the pre-machine pressure setting value multiplied by the compensation coefficient, the pre-boiler pressure Adjust the output of the main regulator; the adjusted quantity of the turbine power regulator is the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com