Oxygen-enriched combustion boiler system and operation method thereof

An oxygen-enriched combustion and boiler technology, applied in the field of boilers, can solve problems such as aggravated corrosion of flue air ducts, and achieve the effects of increasing combustion stability, preventing acid corrosion, and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

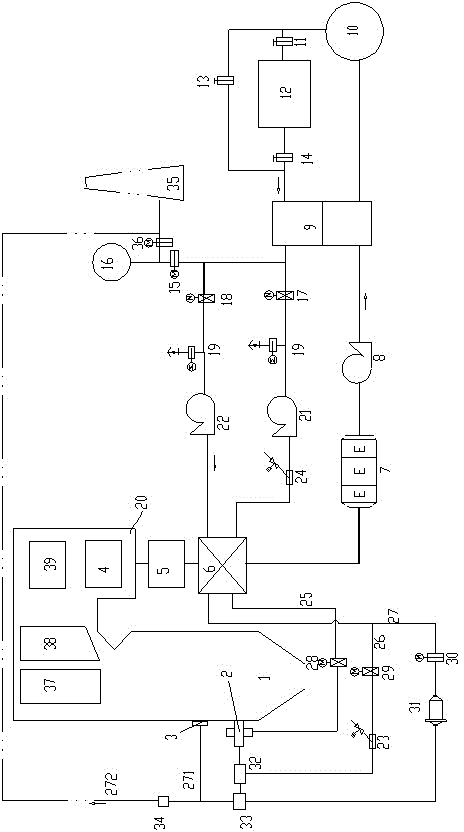

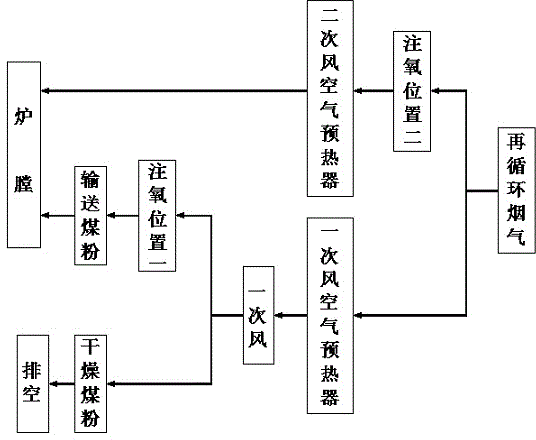

[0036] Such as figure 1 , figure 2 As shown, the oxygen-enriched combustion boiler system of the present invention includes a furnace 1, a burner 2, an overfired air nozzle 3, an economizer 4 located in the tail flue 20, a preheater 6, a dust collector 34 and a chimney 35, and the tail A denitrification device 5 is connected between the outlet of the flue 20 and the exothermic flue gas inlet of the preheater 6, and the exothermic flue gas from the exothermic flue gas outlet of the preheater 6 passes through the dust collector 7 and the flue gas heat exchanger 9 Inlet connection, the exothermic flue gas outlet of the flue gas heat exchanger 9 is connected to the desulfurization device 10 and the flue gas cooler 12 in sequence, and then connected back to the heat-absorbing flue gas inlet of the flue gas heat exchanger 9, and the flue gas cooler 12 Both ends are connected in parallel with a flue gas cooler closing branch with a flue gas cooling control valve 13, a front shut-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com