Combustion furnace with full-automatic feed and heath fuel feed device

A feeding device and furnace technology, applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of unable to meet the continuous long-term fire demand, difficult to meet people's actual needs, and only suitable for household use, etc., to meet the continuous The effect of long-term use of fire demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

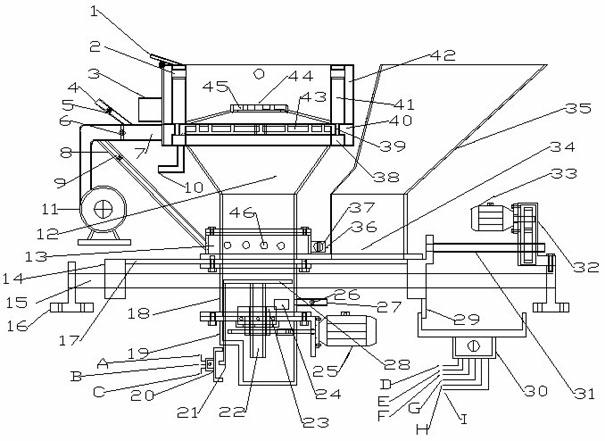

[0017] refer to figure 1 : The fully automatic feeding combustion furnace includes a furnace head part, a furnace body part and a furnace fuel feeding device; the furnace fuel feeding device includes a linear translation device and a linear translation feeding device.

[0018] In the burner section: The flue gas pipe 2 communicates with the smoke collecting layer 42 , and the smoke collecting layer 42 is connected with the chimney 3 , so that the soot gas coming out from the fire outlet 44 is discharged from the chimney 3 . The water inlet 10 is connected to the lower water tank 38, the upper water tank 41 is connected to the lower water tank 38 through the upper and lower water tank connecting pipes 39, the steam outlet 1 is connected to the upper water tank 41, and normal temperature water enters the lower water tank 38 and the upper water tank 41 from the water inlet 10 to be heated. Finally, it turns into steam and is discharged from the steam outlet 1, which plays the r...

Embodiment 2

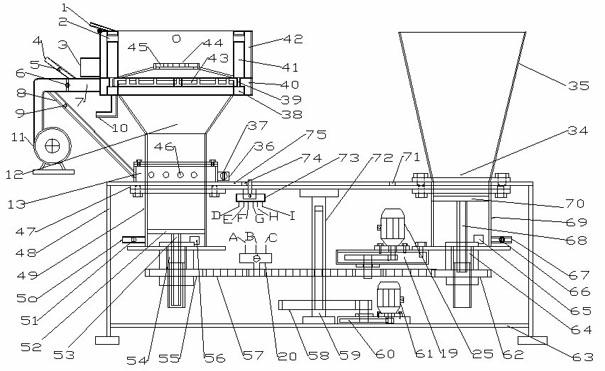

[0034] refer to figure 2 Middle: Furnace head part and furnace body part are similar to embodiment 1; Furnace chamber fuel feeding device comprises rotary translation device and rotary translation feeding device:

[0035] The mouth of the furnace 12 bottom and the funnel outlet 34 at the bottom of the funnel 35 are connected horizontally with the connection port of the fixed platen 75, and the fixed platen 75 is fixedly connected with the support 48;

[0036] The rotation translation device is: The fixed platen 75 and the platen contact surface of the rotating platen 47 are connected by sliding rotation, and the bottom of the rotating platen 47 is vertically connected with the rotating shaft. The connecting device of the machine and the translational platen comprises that the rotating shaft is connected with the rotary motor 61 through the rotary speed changer 60; The platen is symmetrically provided with A feed barrel 49 and B feed barrel 69 relative to the axis of rotati...

Embodiment 3

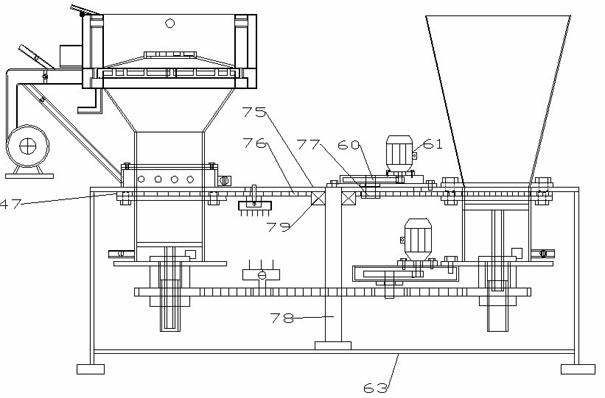

[0051] The burner head part and the furnace body part are similar to Embodiment 1; the furnace fuel feeding device includes a rotary translation device and a rotary translation feeding device, and the rotary translation feeding device is only provided with a single feeding barrel, and the rotary translation device is referred to in Embodiment 2 , feeding device or adopt the feeding device in embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com