Burning furnace burden level control design method, control device and control method

A material level control and design method technology, applied in liquid level control, solid heating fuel, non-electric variable control, etc. The effect of continuous long-term fire demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

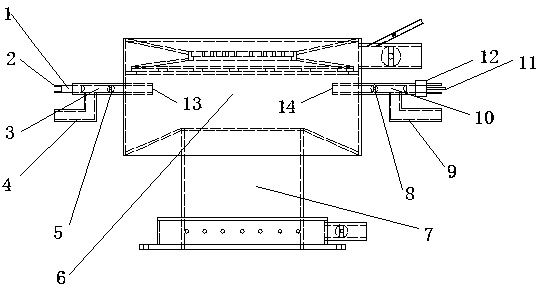

[0025] It includes a detection signal transmitting device, a detection signal receiving device and a feeding control device. A detection signal transmission device and a detection signal receiving device are arranged on both sides of the furnace 6. The detection signal transmission port and the detection signal receiving port are located in the two sides of the furnace 6. Corresponding to the side level, the horizontal emission line of the detection signal emission port is the positioning position of the charge burning.

[0026] The detection signal transmitter head 1 of the detection signal transmitter device is connected to the detection signal transmitter head support 3, the detection signal transmitter head support 3 is connected to the furnace 6, and one end of the detection signal transmitter head support 3 outside the furnace 6 is for transmitter The other end is the detection signal transmitting port 13 in the furnace 6; the furnace 6 is connected with the feed pipe 7. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com