Furnace head of biomass burning furnace

A biomass burning furnace and burner technology, which is applied in the field of domestic furnaces or stoves, can solve the problems of inability to effectively control the material level and feeding, and it is difficult to meet the actual needs of people, so as to meet the needs of continuous long-term use of fire. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

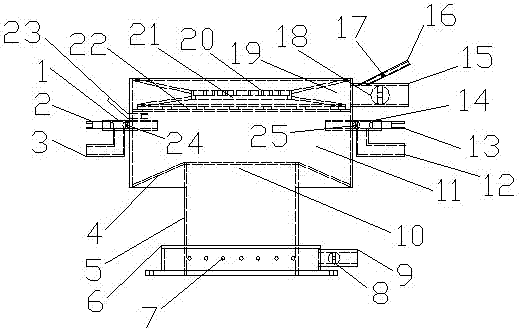

[0021] The furnace mouth part includes an upper air passage air inlet pipe 15, an ignition gas pipe 16, an ignition gas valve 17, an upper air passage valve 18, an upper air passage 19, a fire distribution plate 20, a fire outlet 21 and an upper air passage air outlet 22; The valve 17 is connected with the ignition gas pipe 16, and the ignition gas pipe 16 is connected with the air inlet pipe 15 of the upper air passage. Connect, the air outlet trough that upper air channel 19 is arranged in the direction of burner chamber body 11 inboards is upper air channel air outlet 22, and upper air channel air outlet 22 is communicated with fire outlet 21 by burner chamber body 11, and fire outlet 21 is provided with There is a fire dividing plate 20, and the below of the fire outlet 21 is an upper air duct air outlet 22.

[0022] Both sides of the burner chamber body 11 are provided with a detection signal transmitting device and a detection signal receiving device, and the detection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com