A fire-tube waste heat boiler capable of improving the utilization rate of waste heat

A waste heat boiler and utilization rate technology, applied in the field of waste heat boilers, can solve the problem of low utilization rate of waste heat, achieve the effects of smooth and uniform intake air, slowing down the flow rate, and improving the utilization rate of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

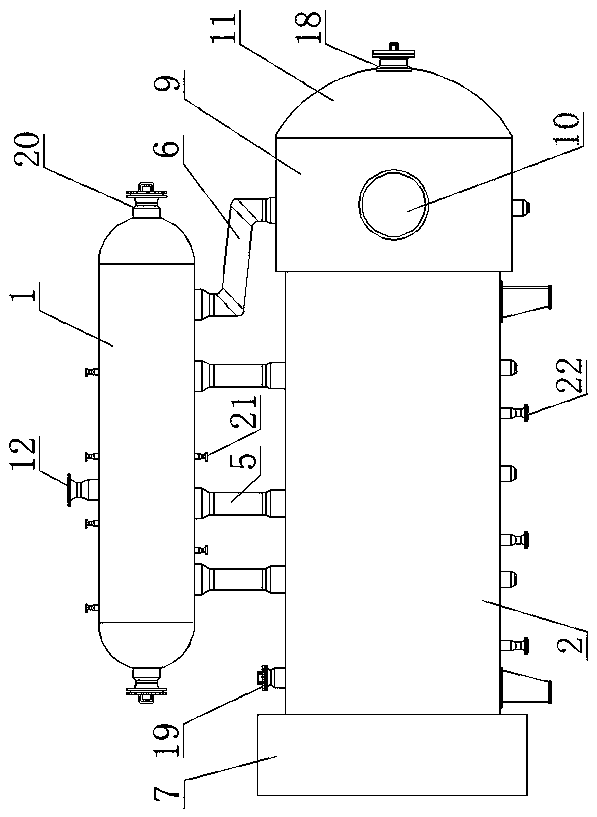

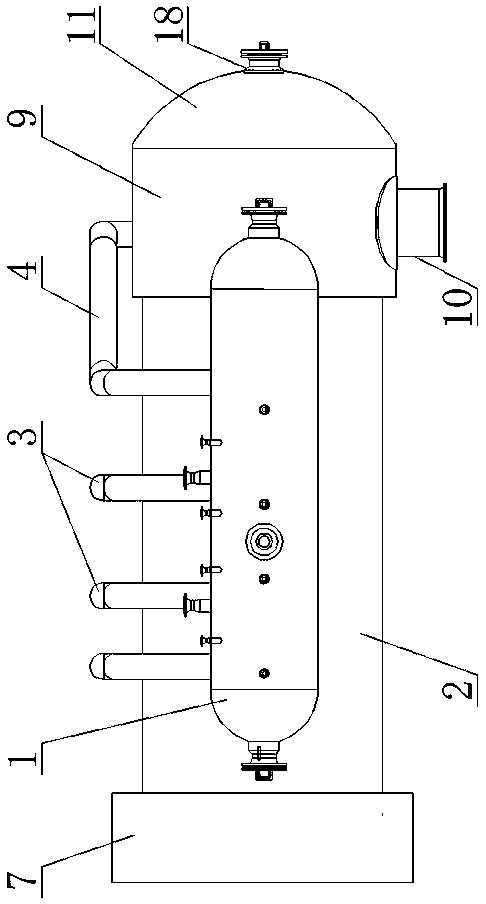

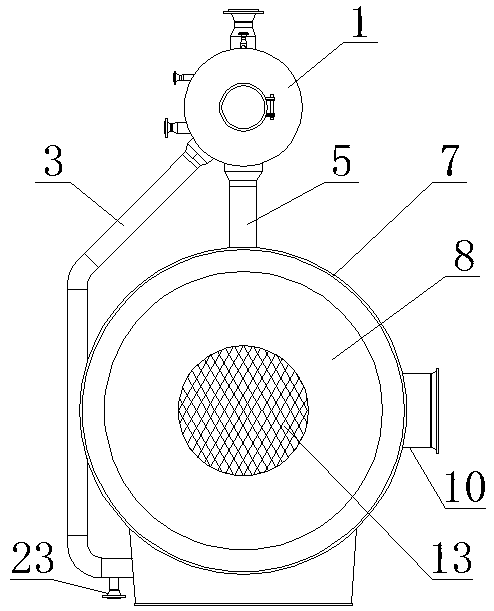

[0023] Referring to the accompanying drawings, the specific implementation is as follows:

[0024] A fire tube waste heat boiler capable of improving the utilization rate of waste heat, comprising a boiler body 2 and a steam drum 1 located above the boiler body 2, the steam drum 1 is provided with a saturated steam outlet 12, and the bottom of the boiler body 2 passes through a plurality of first descending The tube 3 communicates with the steam drum 1, and the top of the boiler body 2 communicates with the steam drum 1 through a plurality of first rising pipes 5. One end of the boiler body 2 is equipped with a front smoke box cylinder 7, and the inner cavity of the front smoke box cylinder 7 A process gas inlet 8 is installed in the middle, a rear smoke box cylinder 9 is installed on the other end of the boiler body 2, and a process gas outlet 10 is installed on the side wall of the rear smoke box cylinder 9, and the rear smoke box cylinder 9 is far away from the boiler body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com