Automatic chicken feed feeding system

A technology of automatic feeding and chicken feed, which is applied in the field of breeding, can solve the problems of low efficiency and high labor cost, and achieve the effect of saving labor cost and realizing automatic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

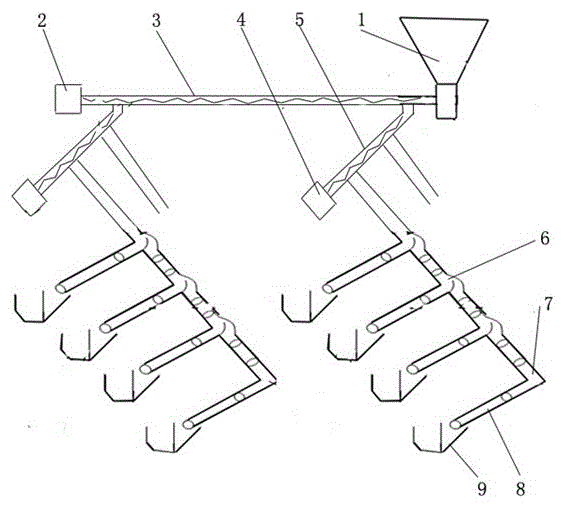

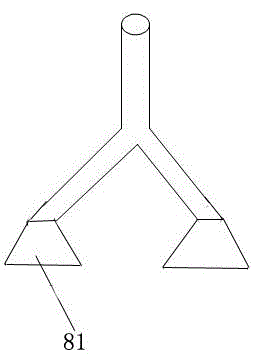

[0024] Such as figure 1 Shown, a kind of chicken feed automatic feeding system comprises material storage device 1, main cage motor 2, main feed pipe 3, sub-cage motor 4 and sub-feed pipe 5, and said main feed pipe 3 is horizontal One end is connected with the storage device 1, and the other end is connected with the main winding cage motor 2. There are several sub-feeding pipes 5, and each sub-feeding pipe 5 is arranged horizontally, and one end is connected to the main shaft through an elbow Below the feeding pipe 3, the other end is connected with the sub-twisting cage motor 4, and several downward-sloping branches are set on the sub-feeding pipe 5, and each branch is connected by several joints from top to bottom in sequence. 6 and the ordinary elbow 7 connected at the bottom.

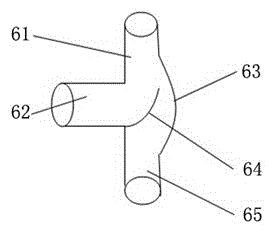

[0025] Such as figure 2 As shown, each section of automatic material distribution tee 6 includes a main pipe, the upper end of the main pipe is a feed port 61, and the lower end is a discharge p...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 lies in that the opposite side wall of the connection between the main pipe and the side distribution pipe 62 protrudes outwards to form a hollow bulge-shaped expansion part 63 .

[0030] Embodiment 1 is suitable for the case where the inner diameter of the distribution baffle 64 is shorter than that of the main pipe, and Embodiment 2 is suitable for the situation where the inner diameter of the distribution baffle 64 is longer than that of the main pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com