Method for reducing cutting overburning of straight flame cutting machine and gas channel

A flame cutting machine, straight bar technology, applied in gas flame welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of cutting, over-cutting, over-burning, and large oxygen consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present technical scheme is further described:

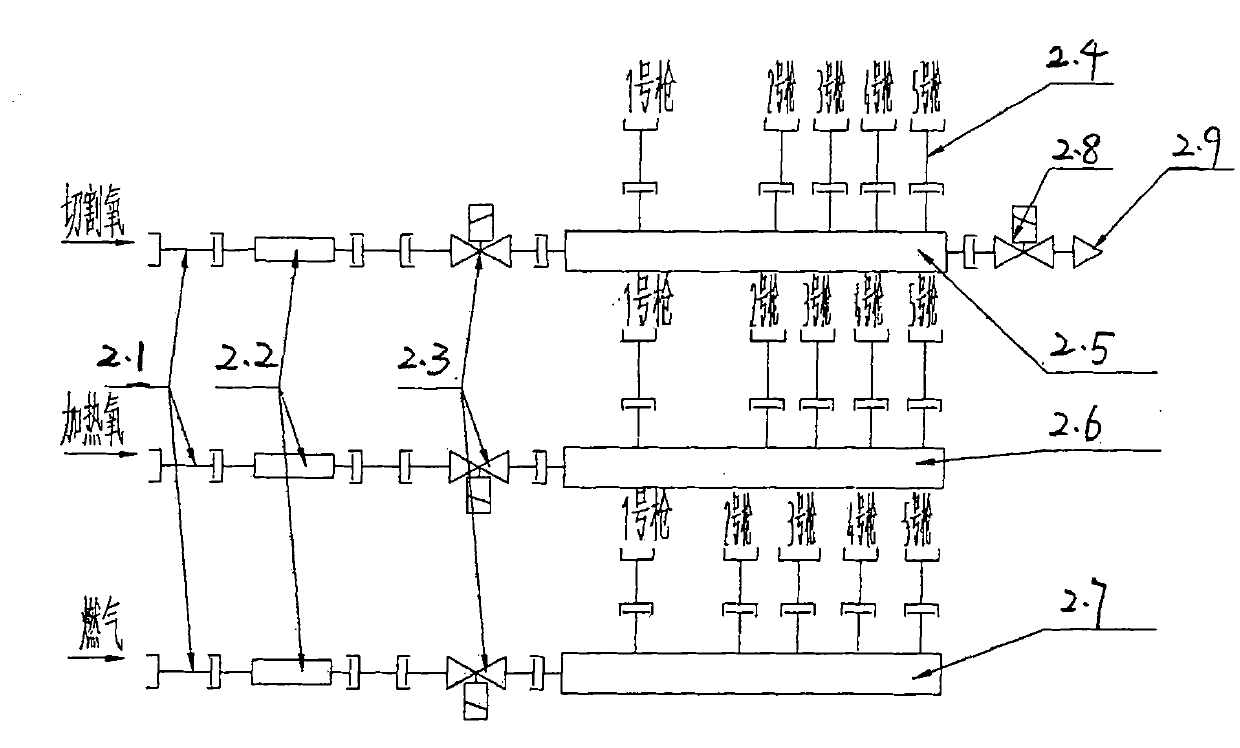

[0023] In this example, when the cutting is closed, the cutting oxygen inlet valve is first turned off, and at the same time, the cutting oxygen gas from the cutting oxygen inlet valve to each flame torch is quickly exhausted, so that the cutting oxygen no longer works and plays a role in cutting oxygen. The role of the switch valve, and then turn off the heating oxygen intake valve and the gas intake valve in turn, and the flame is extinguished thereupon.

[0024] In addition, in the process of exhausting the cutting oxygen, the high-pressure cutting oxygen will be exhausted in a short time, which will generate a lot of noise, so it is necessary to deal with the generated noise, and install a silencer on the exhaust gas path of the cutting oxygen. system.

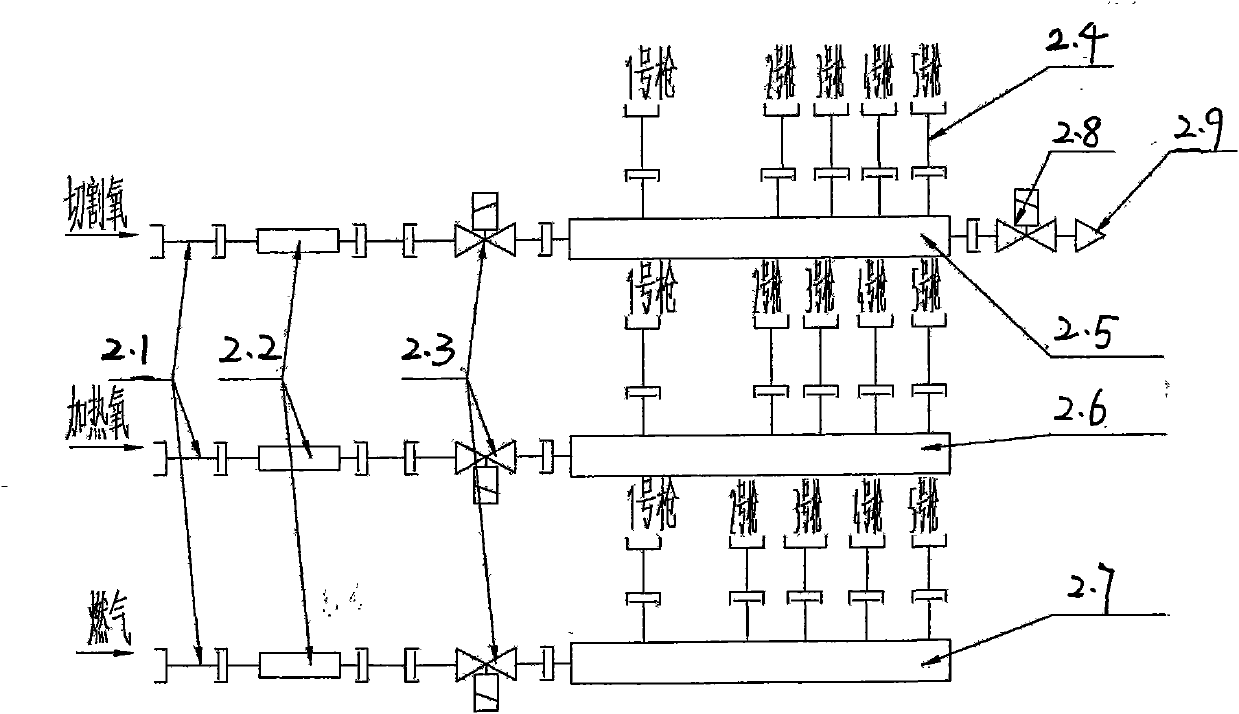

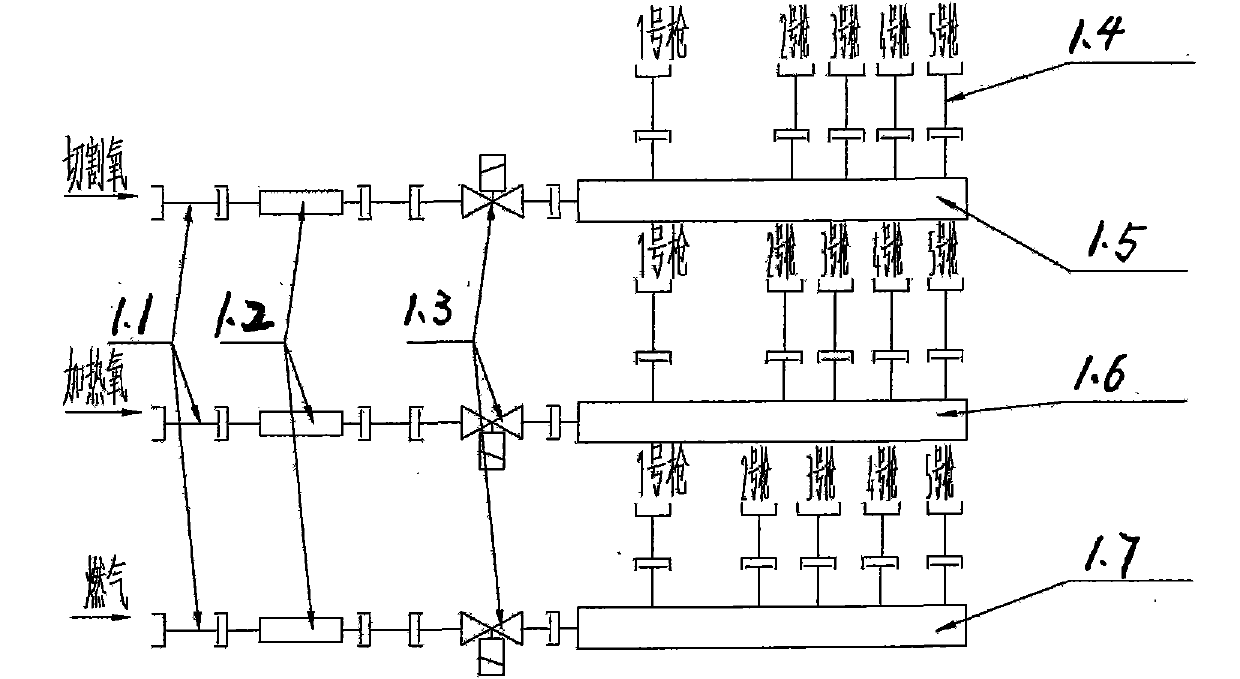

[0025] The specific implementation is to improve the cutting gas path of the existing stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com