Blast-furnace coal powder injection method using waste gas of hot-blast stove flue as carrier

A technology of flue exhaust gas and blast furnace coal injection, which is applied in the field of blast furnace coal injection to achieve the effects of reducing O2 content, increasing combustion speed, and avoiding large emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

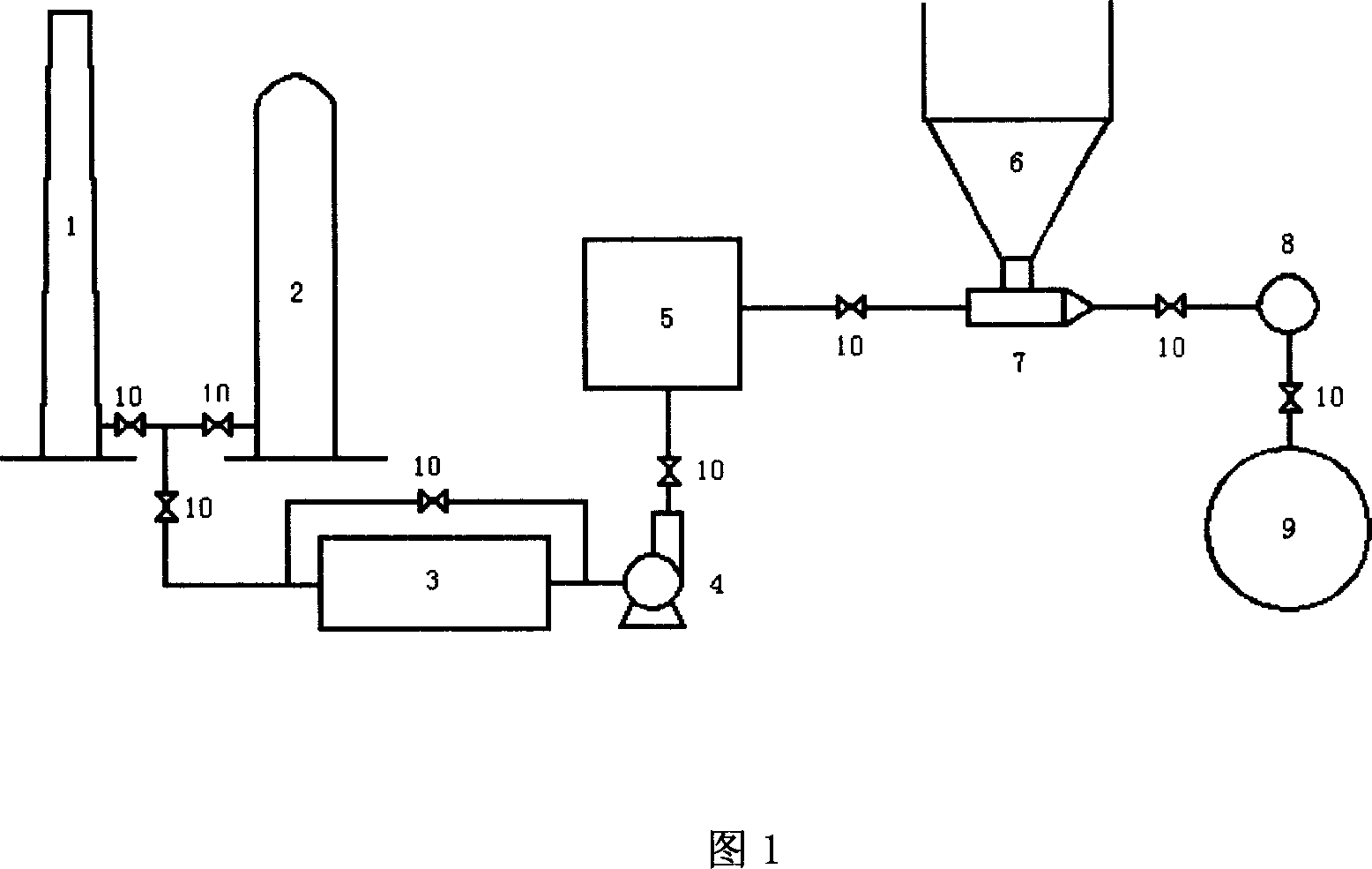

[0019] As shown in Figure 1, the present invention consists of a control valve 10, a heat exchanger 3, an induced draft fan 4, an air compressor 5, an injection tank 6, a coal feeder 7, a distributor 8, special pipes and spray guns, etc. Furnace flue exhaust gas coal injection system, and through this system to form and realize the process flow of connection-extraction-temperature control-pressurization-coal feeding-blowing-distribution-coal injection, so as to realize the use of hot blast stove flue gas as carrier injection Coal pulverized system function.

[0020] Its specific process and implementation steps are:

[0021] The induced draft fan 4 draws the hot blast stove flue waste gas from the flue through a special pipe connected to the hot blast stove flue between the chimney 1 and the hot blast stove 2 . Two passages are arranged at the front of the induced draft fan 4: one is directly connected with the induced draft fan 4, and is controlled by a control valve 10 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com