Method for preparing pyrolytic oil by co-heated pyrolysis and liquefaction of biomass and waste tire

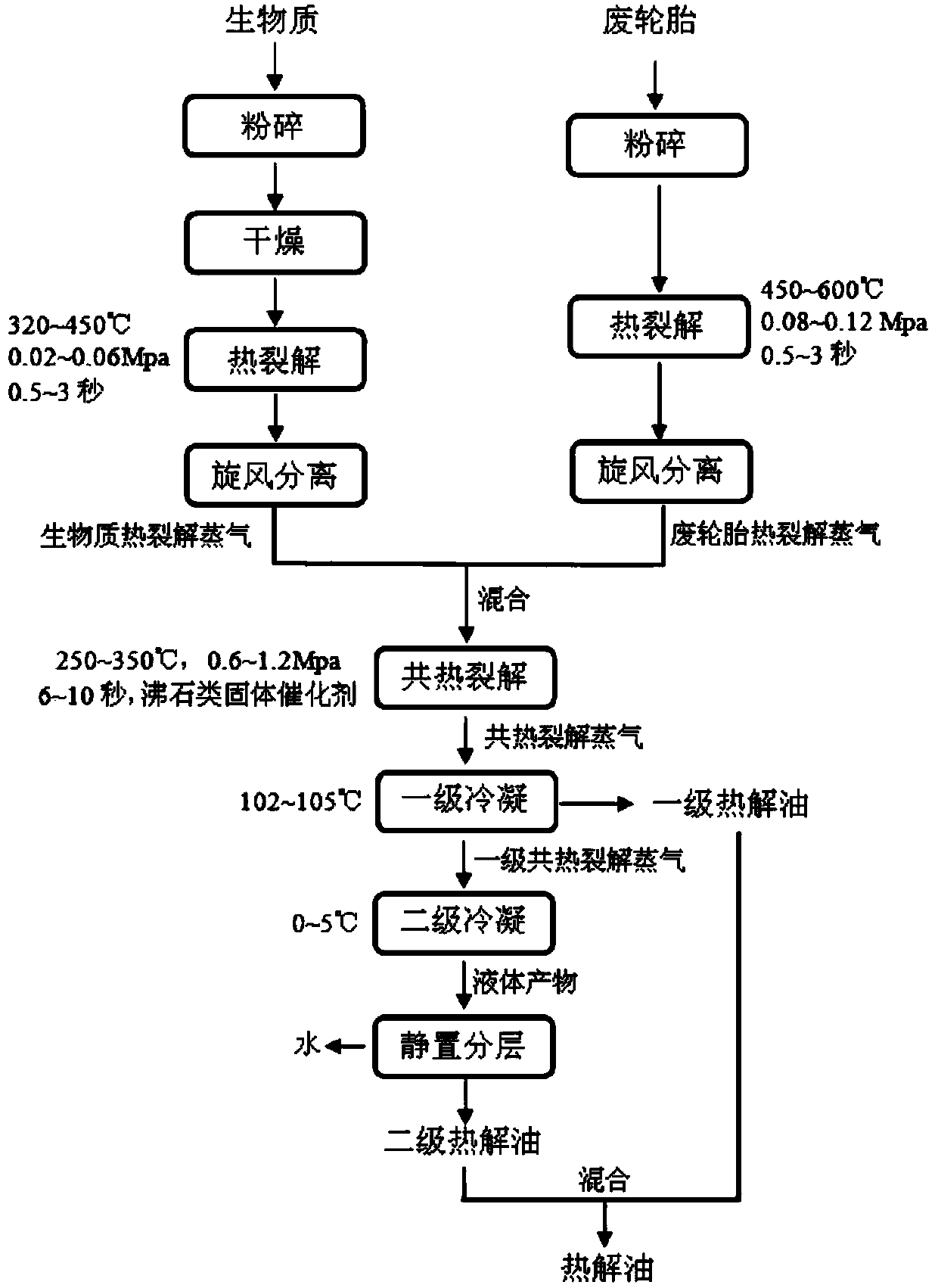

A biomass thermal cracking and waste tire technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of insufficient reaction and insignificant synergistic effect of co-thermal cracking, so as to achieve oil-water separation, improve effect and quality boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking larch and automobile waste tires as an example to introduce the implementation process of the present invention is as follows:

[0029] (1) Crush the larch into particles with a particle size of 1.0 mm, and dry the crushed material so that the moisture content of the material is 8%; crush the waste tire raw material into particles with a particle size of 0.5 mm;

[0030] (2) The larch particles are subjected to pyrolysis reaction under a nitrogen atmosphere, the reaction temperature is 350°C, the reaction pressure is 0.02Mpa, and the reaction time is 2 seconds, and larch pyrolysis steam carrying larch pyrolytic charcoal is generated. performing cyclone separation on larch pyrolysis steam carrying larch pyrolysis carbon to obtain larch pyrolysis steam;

[0031] (3) The waste tire particles are subjected to pyrolysis reaction under nitrogen atmosphere, the reaction temperature is 450°C, the reaction pressure is 0.08Mpa, the reaction time is 2 seconds, and the waste...

Embodiment 2

[0037] Taking corn stalks and waste automobile tires as an example to introduce the implementation process of the present invention is as follows:

[0038] (1) Crush the raw material of corn stalks into particles with a particle size of 2.0 mm, and dry the crushed material so that the moisture content of the material is 10%; crush the raw material of waste tires into particles with a particle size of 1.0 mm;

[0039] (2) The pyrolysis reaction of corn stalk particles is carried out under nitrogen atmosphere, the reaction temperature is 400°C, the reaction pressure is 0.04Mpa, and the reaction time is 0.5 seconds, and the corn stalk pyrolysis steam carrying the corn stalk pyrolysis carbon is generated, and the The corn stalk pyrolysis steam carrying the corn stalk pyrolysis carbon is subjected to cyclone separation to obtain the corn stalk pyrolysis steam;

[0040] (3) The waste tire particles are subjected to pyrolysis reaction under nitrogen atmosphere, the reaction temperatu...

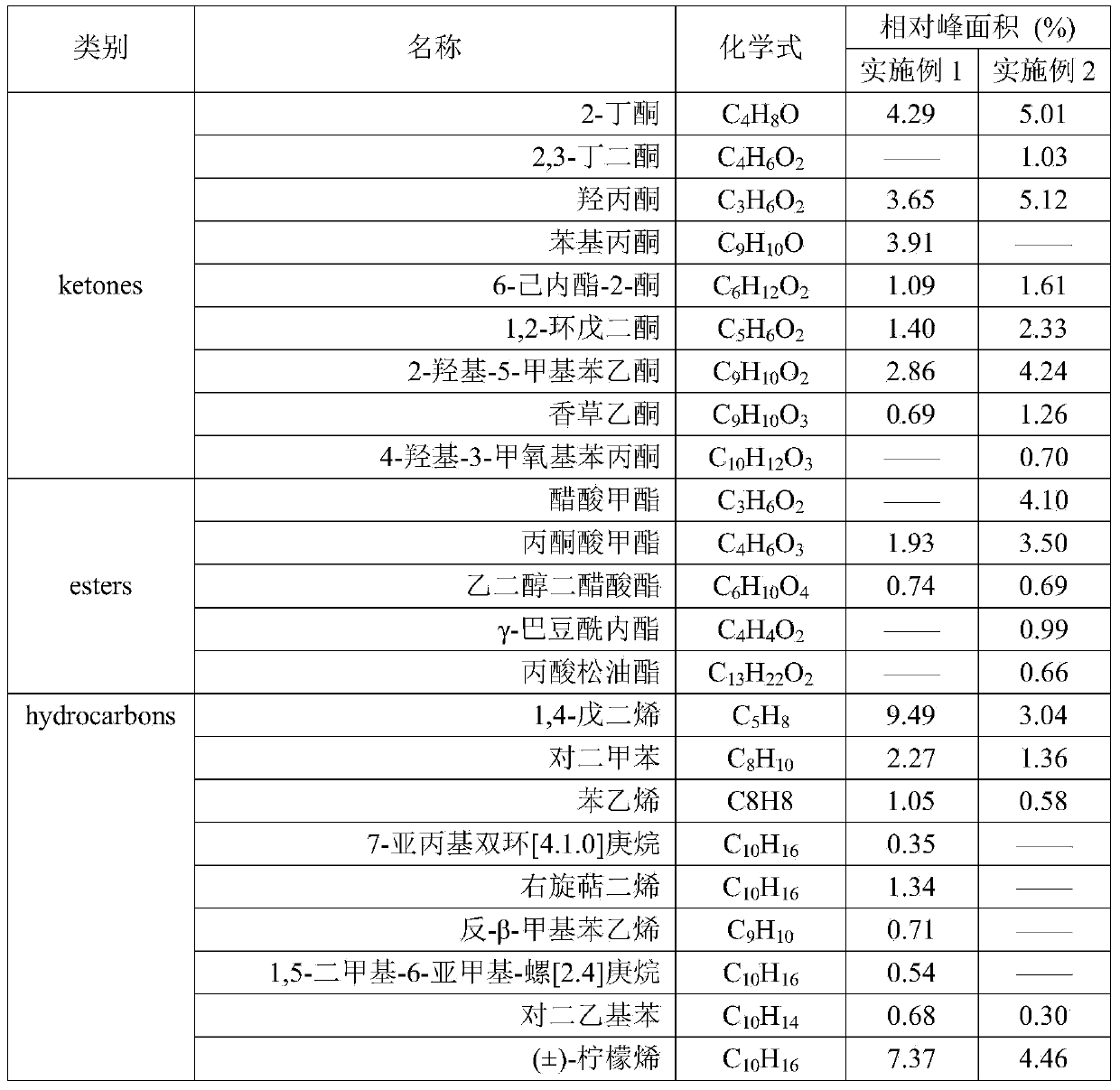

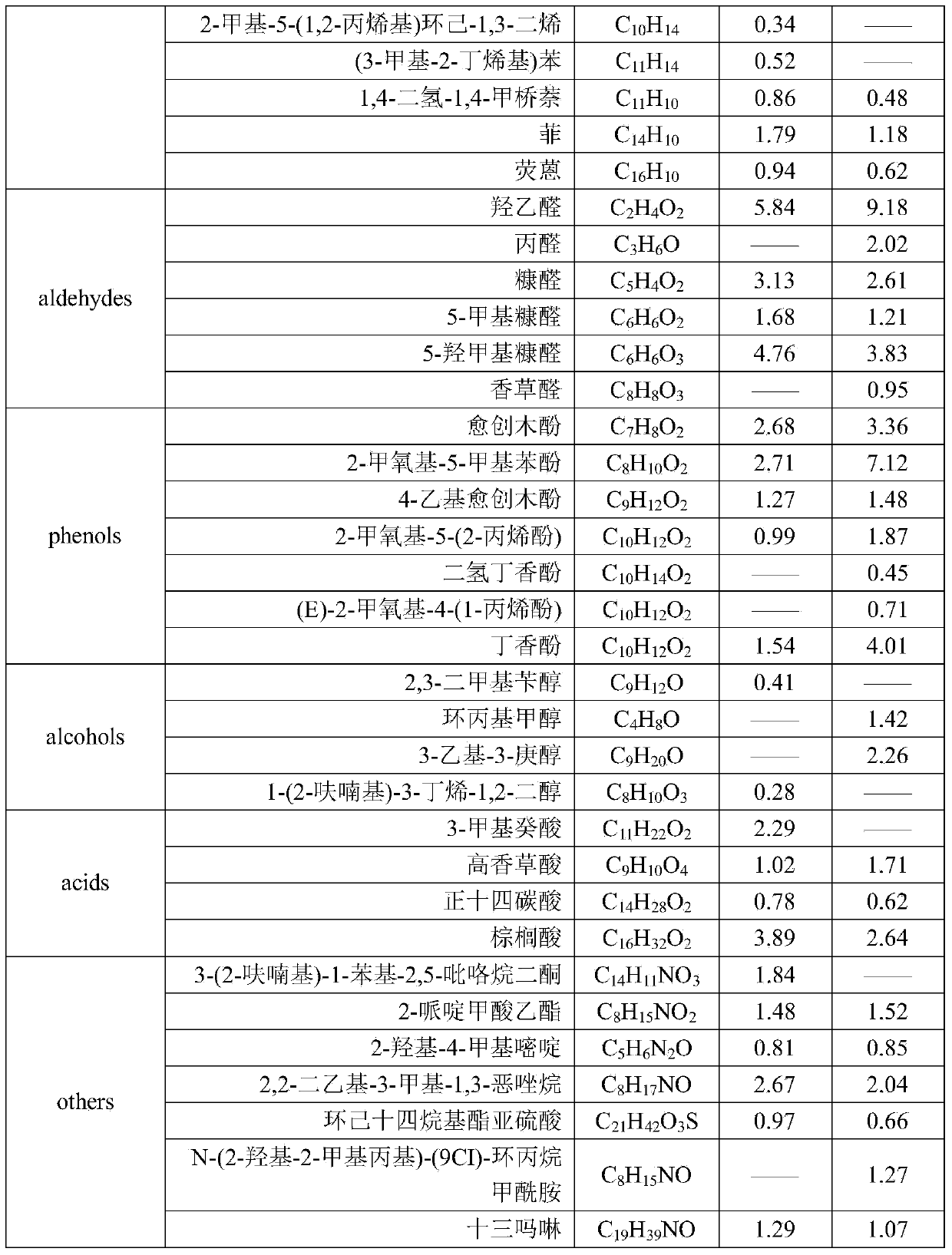

Embodiment 1 and Embodiment 2

[0045] Table 1 Example 1 and Example 2 pyrolysis oil chemical components

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com