Sludge recycling utilization process and system

A recycling and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high equipment loss, large floor area, and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described below with reference to the drawings.

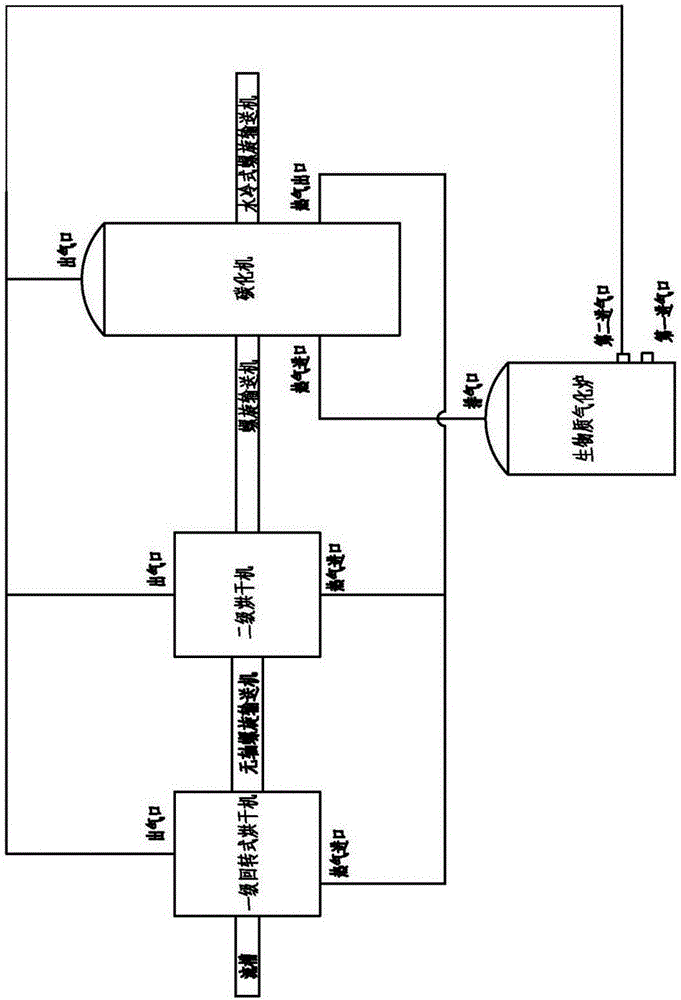

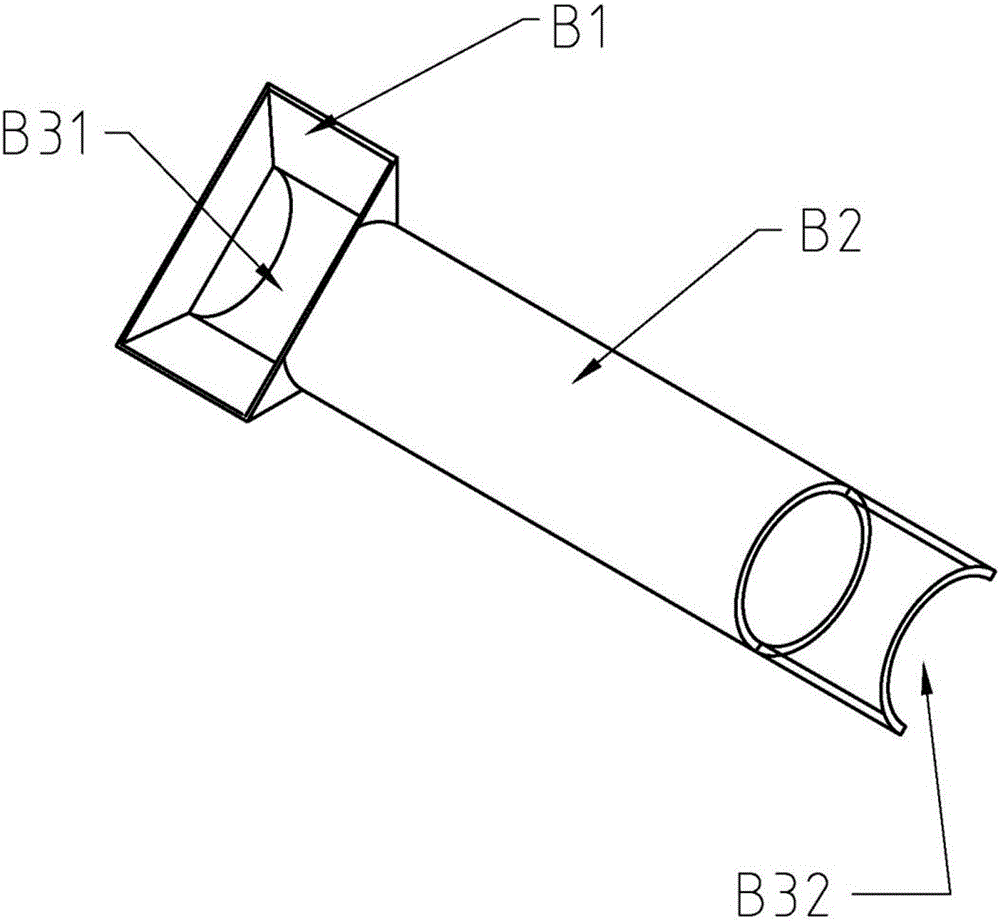

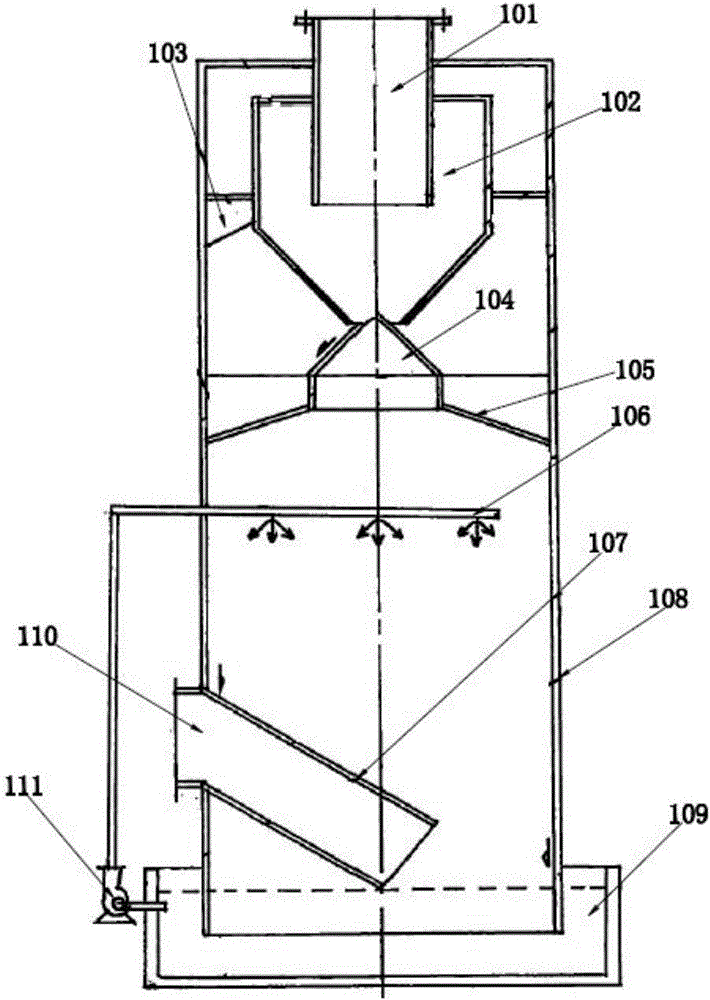

[0020] The invention relates to a sludge resource utilization process, including: primary drying, conveying sludge with a water content of 60% to 100% through a flow trough to a primary rotary dryer with a dispersing shaft for internal drying Dry for 15 minutes to reduce the water content of the sludge to 20-50%, and the heat balance is about 600,000 kcal / hour; secondary drying, the sludge after primary drying is conveyed to the belt by a shaftless screw conveyor The loose shaft secondary dryer is further dried to reduce the water content of the sludge to 2-20%, the sludge particle size is no more than 5 mm, and the heat balance is about 360,000 kcal / hour; carbonization will dry the second time The dried sludge is conveyed to the carbonization machine for carbonization by a screw conveyor. The carbonization machine is heated by a biomass gasifier of 1 million kcal. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com