Alkali lignin carbon nanometer microsphere as well as preparation method and application thereof

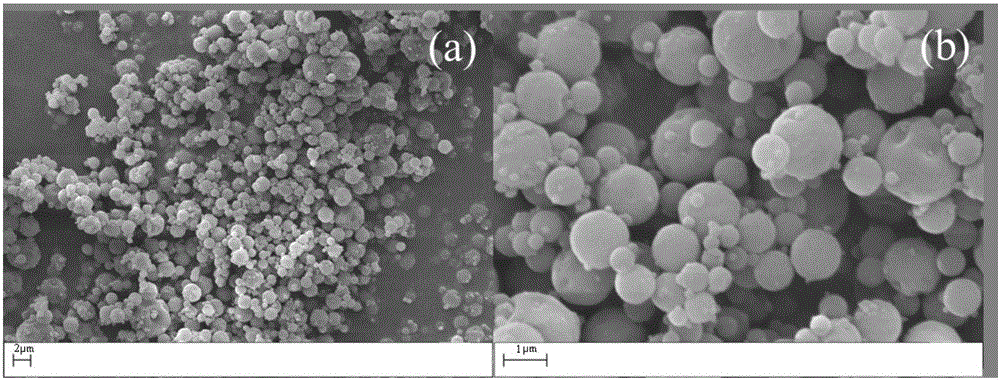

A technology of carbon nanospheres and alkali lignin, which is applied in the direction of nanotechnology, can solve the problems that carbon materials are difficult to maintain shape, nanostructures are easily damaged, and the cost is high, and achieve good practical application value, good microscopic appearance, and improved The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weighing commercial alkali lignin, using N,N-dimethylformamide as a solvent, configured as an alkali lignin electrostatic spray solution with a mass fraction of 35%;

[0026] (2) the alkali lignin electrostatic spray solution of step (1) is transferred in the equipment of electrostatic spray, is 25kv at static voltage, and receiving distance is 15cm, carries out electrostatic spray under the condition that the propulsion speed of electrostatic spray solution is 3ml / h , to obtain alkali lignin nano-microspheres;

[0027] (3) The alkali lignin nanospheres are placed in a tube furnace, and the alkali lignin nanospheres are preoxidized at a preoxidation temperature of 250°C. The preoxidation is carried out in air, and the heating rate is 0.2°C / min , the pre-oxidation time is 2h;

[0028] (4) Carry out carbonization treatment on the pre-oxidized alkali lignin nano-microspheres, the carbonization temperature is 400°C, the carbonization treatment is carried out in nitroge...

Embodiment 2

[0031] (1) Weighing commercial alkali lignin, using N,N-dimethylformamide as a solvent, configured as an alkali lignin electrostatic spray solution with a mass fraction of 45%;

[0032] (2) the alkali lignin electrostatic spray solution of step (1) is transferred in the equipment of electrostatic spray, is 15kv at static voltage, and receiving distance is 15cm, carries out electrostatic spray under the condition that the propulsion speed of electrostatic spray solution is 3ml / h , to obtain alkali lignin nano-microspheres;

[0033] (3) The alkali lignin nanospheres are placed in a tube furnace, and the alkali lignin nanospheres are preoxidized at a preoxidation temperature of 280°C. The preoxidation is carried out in air, and the heating rate is 0.5°C / min , the pre-oxidation time is 2h;

[0034] (4) Carry out carbonization treatment on the pre-oxidized alkali lignin nano-microspheres, the carbonization temperature is 400°C, the carbonization treatment is carried out in nitroge...

Embodiment 3

[0036] (1) Weigh commercial alkali lignin, use glacial acetic acid as a solvent, and configure it as an alkali lignin electrostatic spray solution with a mass fraction of 25%;

[0037] (2) the alkali lignin electrostatic spray solution of step (1) is transferred in the equipment of electrostatic spray, is 15kv at static voltage, and receiving distance is 10cm, carries out electrostatic spray under the condition that the propulsion speed of electrostatic spray solution is 2ml / h , to obtain alkali lignin nano-microspheres;

[0038] (3) The alkali lignin nanospheres are placed in a tube furnace, and the alkali lignin nanospheres are preoxidized at a preoxidation temperature of 280°C. The preoxidation is carried out in air, and the heating rate is 0.2°C / min , the pre-oxidation time is 2h;

[0039] (4) Carry out carbonization treatment on the pre-oxidized alkali lignin nano-microspheres, the carbonization temperature is 600°C, the carbonization treatment is carried out in argon, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com