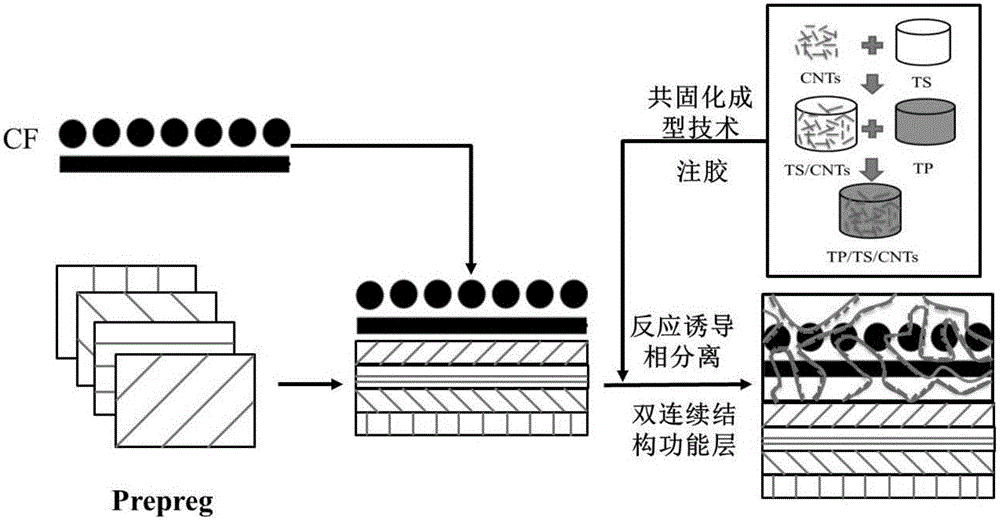

Composite material function modification method based on co-curing and reaction inductive phase separation

A composite material and induced phase technology is applied in the field of functional modification of composite materials, which can solve the problems that the electrical and thermal conductivity of resin cannot be effectively improved, the electrical conductivity of resin cannot be improved, and carbon nanotubes are difficult to enter, and the co-curing process is simple and cost-effective. Low, use-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of carbon fiber composite materials with lightning strike and deicing functions based on the E51 / PEI / CNTs hybrid system

[0040] Dissolve polyetherimide (PEI) in dichloromethane, and evaporate most of the solvent at room temperature; add carbon nanotubes to liquid epoxy resin E51 at a ratio of 1 to 5 wt%, and use mechanical stirring and ultrasonic dispersion, etc. The device is stirred evenly. Add PEI into the liquid epoxy resin mixed with carbon nanotubes in the proportion of 10-30wt%, and use mechanical stirring and ultrasonic dispersion to stir evenly to obtain a stable E51 / PEI / CNTs mixed system. Cut the carbon fiber prepreg and lay it up according to [45° / 0° / -45° / 90°] to obtain a laminated prepreg structure. Cut the dry carbon fiber cloth and lay up layers according to [45° / 0° / -45° / 90°] to obtain a dry carbon fiber preform. The laminated prepreg structure and dry carbon fiber preform are brought together. In the prepared E51 / PEI / CNTs materi...

Embodiment 2

[0044] Example 2: Preparation of carbon fiber composite materials with lightning strike and deicing functions based on the E51 / PES / CNTs hybrid system

[0045] Add carbon nanotubes into liquid epoxy resin E51 at a ratio of 1 to 5 wt%, and stir evenly with devices such as mechanical stirring and ultrasonic dispersion; Heat-melt it into the liquid epoxy resin mixed with carbon nanotubes at high temperature, and use mechanical stirring and ultrasonic dispersion to stir evenly to obtain a stable E51 / PES / CNTs mixed system. According to the method of Example 1, a carbon fiber composite material with a lightning-resistant and deicing surface functional layer was obtained.

Embodiment 3

[0046] Example 3: Preparation of a structure-function integrated composite material with wave-absorbing and stealth functions

[0047] The functional particles in the above-mentioned Example 1 were replaced with carbonyl iron powder and FeNi nano-powder with a content of 1 to 5 wt%. According to the method of Example 1, a composite material with a surface functional layer was obtained. The test results showed that: Compared with the composite material control group of particles, the composite material of the present invention has higher microwave absorption effect and higher interlayer crack resistance performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com