Conductive polymer composite material with continuous isolation structure and preparation method thereof

A technology of conductive polymer and composite material, applied in the field of conductive polymer composite material with continuous isolation structure and its preparation, can solve the problem of poor mechanical properties such as rigidity and toughness, limiting the application of conductive polymer materials, and poor mechanical properties of conductive materials. and other problems, to achieve the effect of high modulus, good comprehensive performance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second technical problem to be solved in the present invention is to provide the preparation method of the above-mentioned conductive polymer composite material, which includes the following steps:

[0045] Step 1. Using two polymers that can form a co-continuous structure as a matrix, and using conductive particles that can be selectively dispersed in one of the polymer phases as a filler, the three are melt blended to obtain a double percolation Structural conductive composite samples;

[0046] Step 2. Use a specific solvent to selectively dissolve the one-phase polymer containing nanoparticles in the sample obtained in step 1, and then remove the solvent at a certain rate, and the nanoparticles are deposited on the surface of the remaining holes during the solvent removal process. , to obtain a porous material containing a conductive filler;

[0047] Step 3: Pressing the porous material obtained in Step 2 at a certain temperature with a certain pressure for a cert...

Embodiment 1

[0051] Embodiment 1PP / CB conductive composite material and preparation thereof

[0052] Polymer 1 is PP, the conductive filler is carbon black, the introduction of polymer 2 is PS, and the mass ratio of PP to PS is 50:50; the preparation method is as follows:

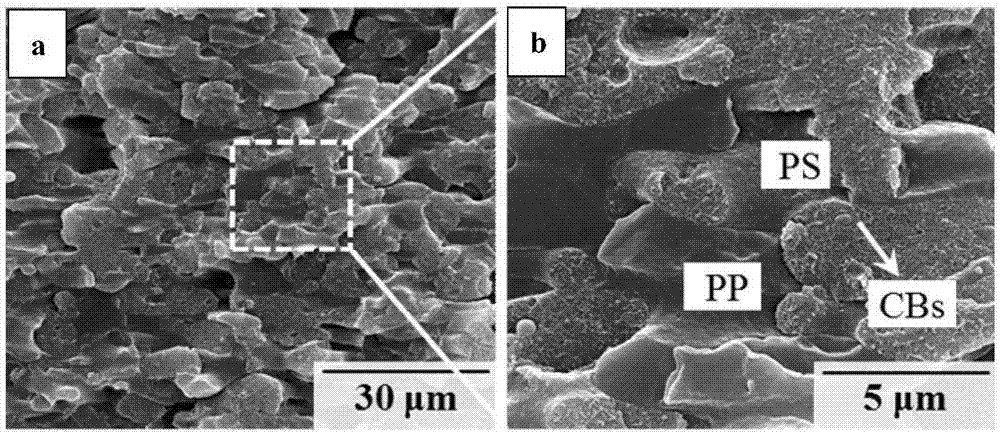

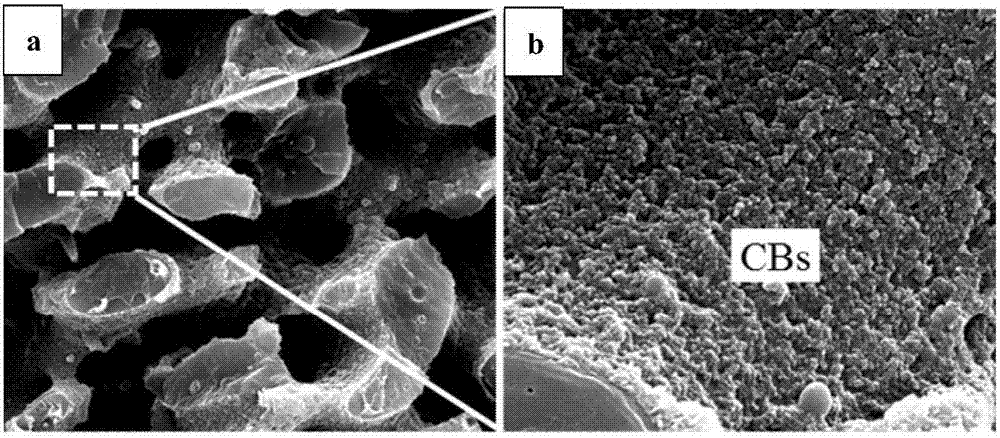

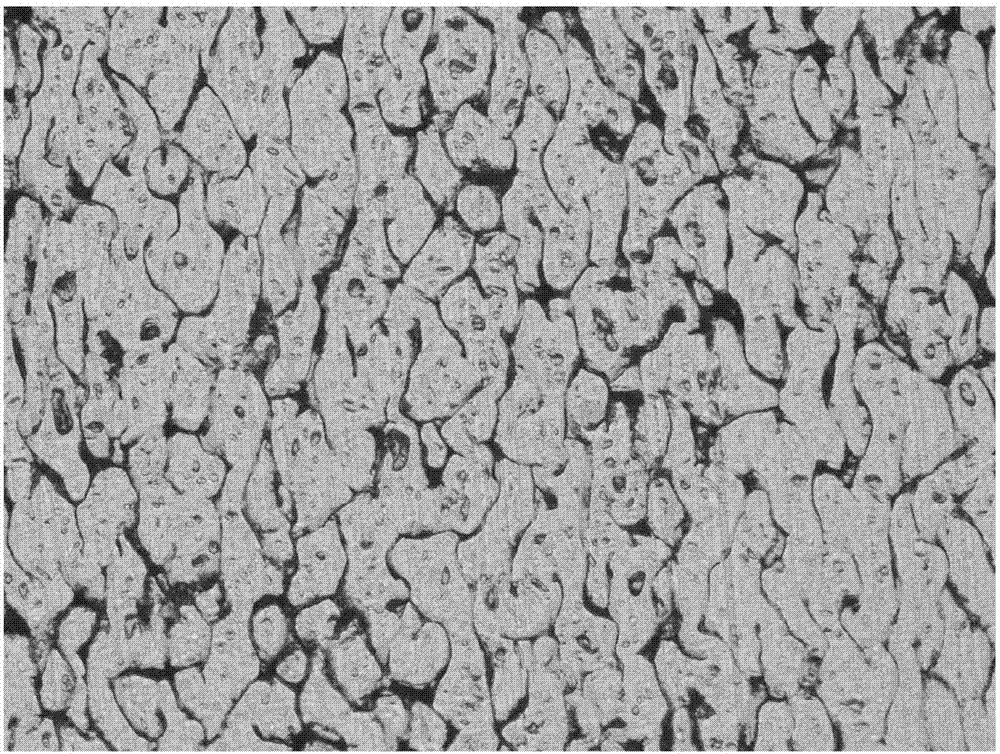

[0053] Step 1. Under the condition of 190°C and 50rpm, in a torque rheometer (XSS-300 type, produced by Shanghai Qingji Mold Factory), first integrate PS with different contents of CB (CB accounts for PP / PS blends) 0, 0.05%, 0.1%, 0.2%, 0.4%, 1%, 2%, 3%, 4%, 5%, 6%) blending for 3min, then adding PP to continue blending for 5min under the same conditions , to obtain a PP / PS / CB ternary blend with a double percolation structure; the SEM image of the obtained ternary blend is shown in figure 1 shown by figure 1 It can be seen that the two phases of PP and PS are continuous structures, and the blend presents a co-continuous structure, in which CB particles are selectively distributed in the PS phase, and there are no CB p...

Embodiment 2

[0056] Embodiment 2PP / MWCNT conductive composite material and its preparation

[0057] Polymer 1 is PP, the conductive filler is multi-walled carbon nanotubes, polymer 2 is introduced as PS, and the mass ratio of PP to PS is 50:50; the preparation method is as follows:

[0058] Step 1. Under the conditions of 190°C and 50rpm, in a torque rheometer (XSS-300, produced by Shanghai Qingji Mold Factory), first integrate PS with different contents of MWCNT (MWCNT accounts for PP / PS blends) 0, 0.05%, 0.1%, 0.2%, 0.4%, 1%, 2%, 3%, 4%, 5%, 6%) blending for 3min, then adding PP to continue blending for 5min under the same conditions , to obtain a PP / PS / MWCNT ternary blend with a double percolation structure, wherein the MWCNT is selectively distributed in PS;

[0059] Step 2. Soak the PP / PS / MWCNT ternary blend obtained in step 1 in xylene for one week to ensure that the PS phase in the sample is completely and selectively dissolved, and then put the sample in an oven and dry it at 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com