A preparation method of nylon 6-graphene composite with excellent electrical conductivity and thermodynamic properties

A technology of thermodynamic performance and electrical conductivity, applied in the field of nanocomposite materials, to achieve the effect of improving thermodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Mix 2 g of expanded graphite, 350 mL of concentrated sulfuric acid, and 2 g of potassium permanganate into a 500 mL three-necked flask, and react at 35°C for 1 hour to obtain low-oxidation expanded graphite (EGIC).

[0024] 2) Add the above-mentioned EGIC to 300 mL of deionized water, and add 2 g of surfactant OP-15, and perform ultrasound for 1 hour to obtain a low-oxidized graphene aqueous solution. Then take 20 mL of the above graphene aqueous solution by centrifugation to remove the upper layer liquid, and redisperse the lower layer of graphene into 50 mL of ethanol by shearing.

[0025] 3) Add 30 g of nylon 6 powder to the ethanol solution of the above graphene, stir for 2 hours, then filter through a mesh to obtain a wet nylon 6-graphene composite, and dry it overnight in a vacuum. Finally, the composite was molded at 200°C and 10 MPa. The final graphene content in the composite is 0.4 wt%.

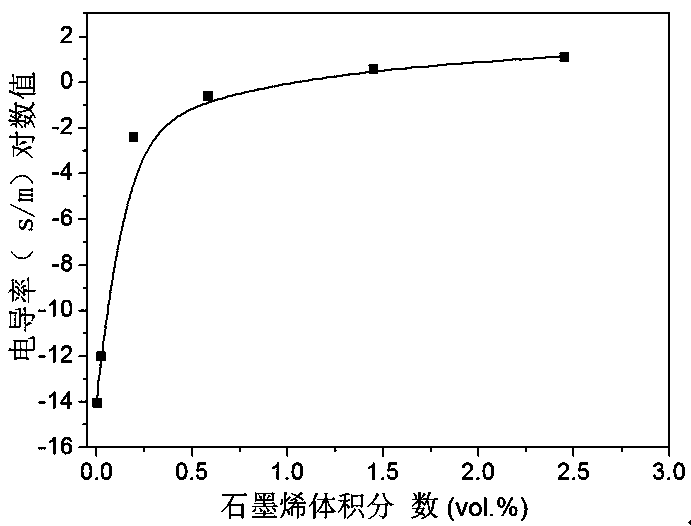

[0026] From figure 1 It can be concluded that in this embodiment, the cond...

Embodiment 2

[0028] 1) Mix 2 g of expanded graphite, 350 mL of concentrated sulfuric acid, and 2 g of potassium permanganate into a 500 mL three-necked flask, and react at 35°C for 1 hour to obtain low-oxidation expanded graphite (EGIC).

[0029] 2) Add the above-mentioned EGIC to 300 mL of deionized water, and add 2 g of surfactant OP-15, and perform ultrasound for 1 hour to obtain a low-oxidized graphene aqueous solution. Then take 37 mL of the above graphene aqueous solution by centrifugation to remove the upper layer liquid, and redisperse the lower layer of graphene into 70 mL of ethanol by shearing.

[0030] 3) Add 25 g of nylon 6 powder to the ethanol solution of the above graphene, stir for 2 hours, then filter through a screen to obtain a wet nylon 6-graphene composite, and dry it overnight in a vacuum. Finally, the composite was molded at 200°C and 10 MPa. The final graphene content in the composite is 1.2 wt%.

[0031] From figure 1 It can be concluded that in this example, the condu...

Embodiment 3

[0033] 1) Mix 2 g of expanded graphite, 380 mL of concentrated sulfuric acid, and 2 g of potassium permanganate into a 500 mL three-necked flask, and react at 35°C for 1 hour to obtain expanded graphite (EGIC) with a low degree of oxidation.

[0034] 2) Add the above-mentioned EGIC to 300 mL of deionized water, and add 2 g of surfactant OP-15, and perform ultrasound for 1 hour to obtain a low-oxidized graphene aqueous solution. Then take 75 mL of the above graphene aqueous solution by centrifugation to remove the upper layer, and redisperse the lower layer of graphene into 80 mL of ethanol by shearing.

[0035] 3) Add 15 g of nylon 6 powder to the above-mentioned graphene ethanol solution, stir for 2 hours, and then filter through a screen to obtain a wet nylon 6-graphene composite, and dry it overnight in a vacuum. Finally, the composite was obtained by compression molding at 210°C and 10 MPa. The final graphene content in the composite is 3 wt%.

[0036] From figure 1 It can be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com