A kind of polyolefin-based conductive and dielectric composite material and preparation method thereof

A polyolefin and conductive filler technology, which is applied in the field of polyolefin-based conductive and dielectric composite materials and their preparation, can solve the problems of poor mechanical properties of conductive materials, complex processing technology, low percolation, etc., and achieve high strength and toughness , good overall performance, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

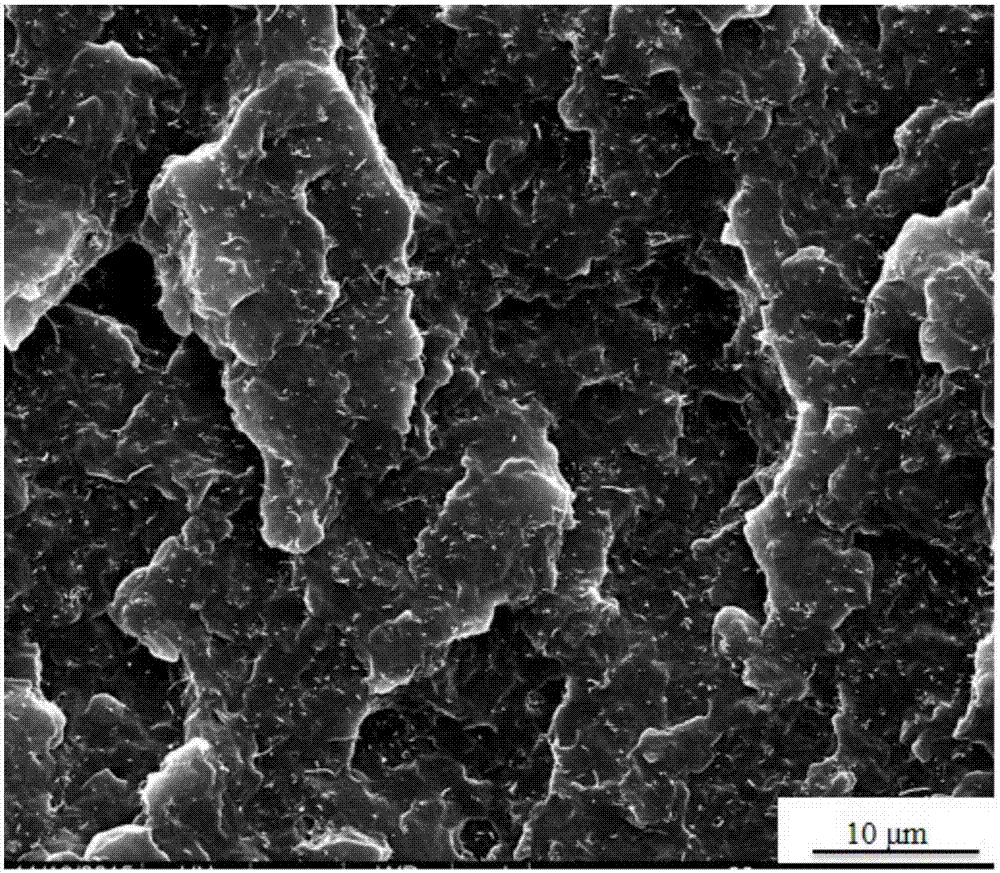

Embodiment 1

[0032] Polypropylene / ethylene-octene block copolymer (PP / OBC) blend with a mass ratio of 80:20 is used as the polymer matrix, and multi-walled carbon nanotubes (MWCNT) are used as conductive filler particles; at 190°C, 80rpm Under conditions, in the torque rheometer (XSS-300 type, produced by Shanghai Qingji Mold Factory), OBC and different contents (1,3,5,7,9,11,13,15wt%), conductive filler The content refers to the mass percentage of MWCNT in the total amount of PP / OBC) MWCNT was blended for 3 minutes, and then PP was added to continue blending under the same conditions for 8 minutes to obtain a PP / OBC / MWCNT composite material with uniformly dispersed MWCNT. The obtained composite material was pressed at 190°C and 10 MPa for 5 minutes, and then cooled to obtain a PP / OBC / MWCNT sheet, and its electrical and mechanical properties were tested.

Embodiment 2

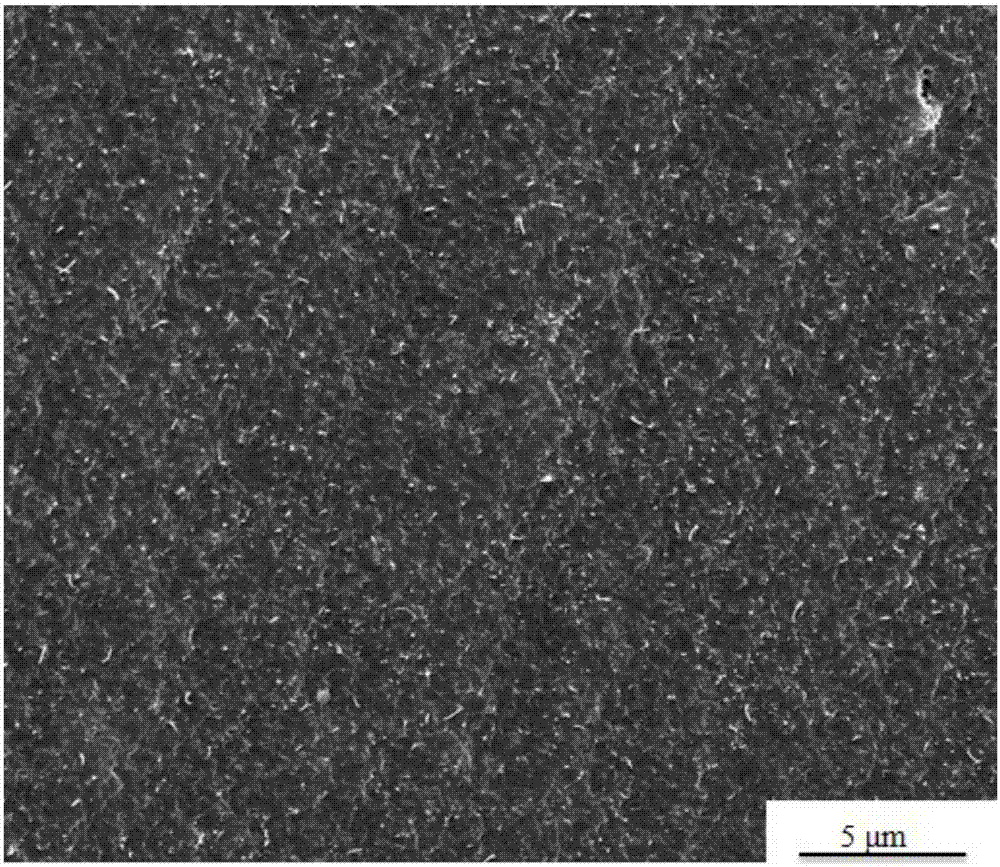

[0034] A high-density polyethylene / ethylene-octene block copolymer (HDPE / OBC) blend with a mass ratio of 80:20 is used as the polymer matrix, and multi-walled carbon nanotubes (MWCNT) are used as conductive filler particles; at 190°C , under the condition of 80rpm, in the torque rheometer (XSS-300 type, produced by Shanghai Qingji Mold Factory), firstly mix OBC with different contents (the contents are respectively 1,3,5,7,9,11,13, 15 wt%) of MWCNT was blended for 3 minutes, and then HDPE was added to continue blending under the same conditions for 8 minutes to obtain a HDPE / OBC / MWCNT composite material with uniformly dispersed carbon tubes. The obtained composite material was pressed at 190°C and 10 MPa for 5 minutes, and after cooling, HDPE / OBC / MWCNT sheets were obtained, and their electrical and mechanical properties were tested.

Embodiment 3

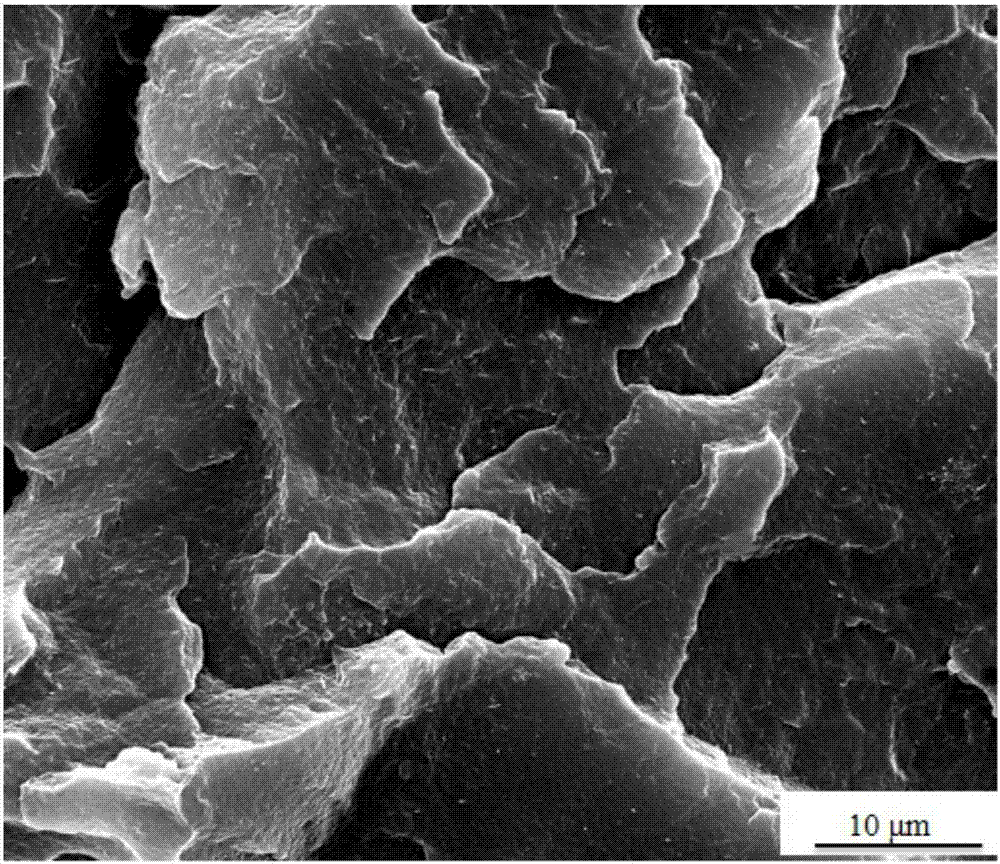

[0036]The low-density polyethylene / ethylene-octene block copolymer (LDPE / OBC) blend with a mass ratio of 80:20 is used as the polymer matrix, and the multi-walled carbon nanotube (MWCNT) is used as the conductive filler particle; at 190°C , under the condition of 80rpm, in the torque rheometer (XSS-300 type, produced by Shanghai Qingji Mold Factory), first mix OBC with different contents (1,3,5,7,9,11,13,15wt%) The MWCNTs were blended for 3 minutes, and then LDPE was added to continue blending for 8 minutes under the same conditions to obtain LDPE / OBC / MWCNT composites with uniformly dispersed carbon tubes. The obtained composite material was pressed at 190°C and 10MPa for 5 minutes, and after cooling, LDPE / OBC / MWCNT sheets were obtained, and their electrical and mechanical properties were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com